Graphene mass production equipment and manufacturing method thereof

A manufacturing method, graphene technology, applied in the direction of graphene, single-layer graphene, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

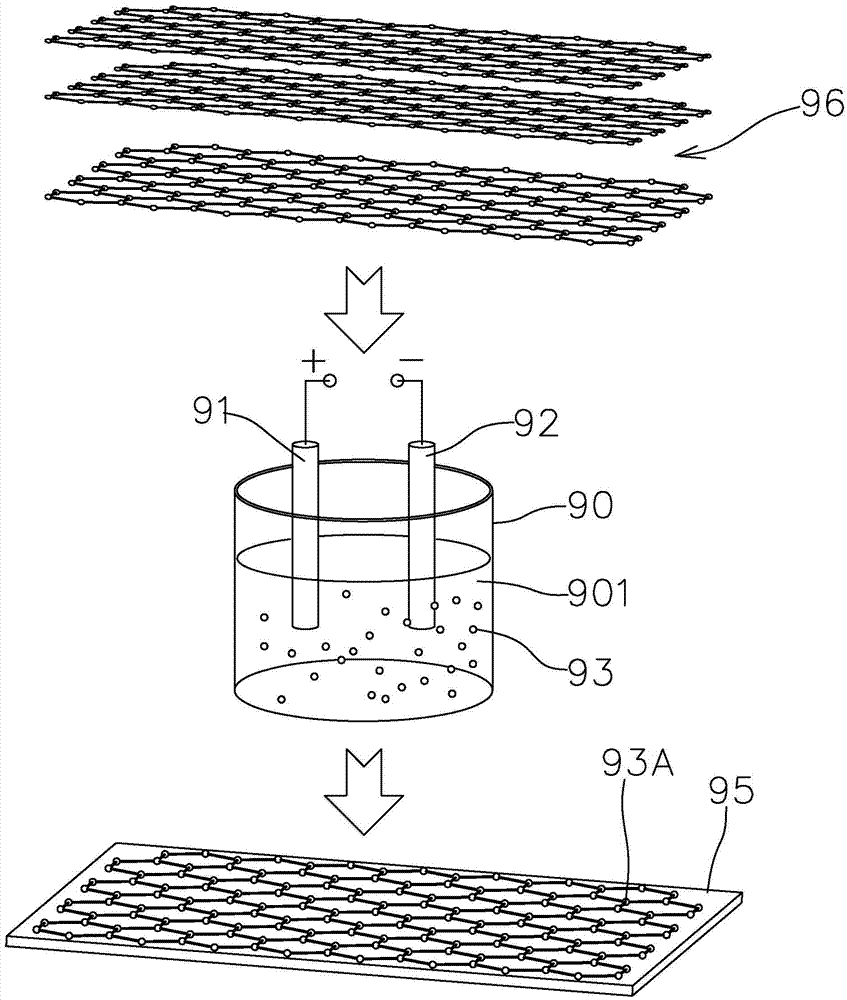

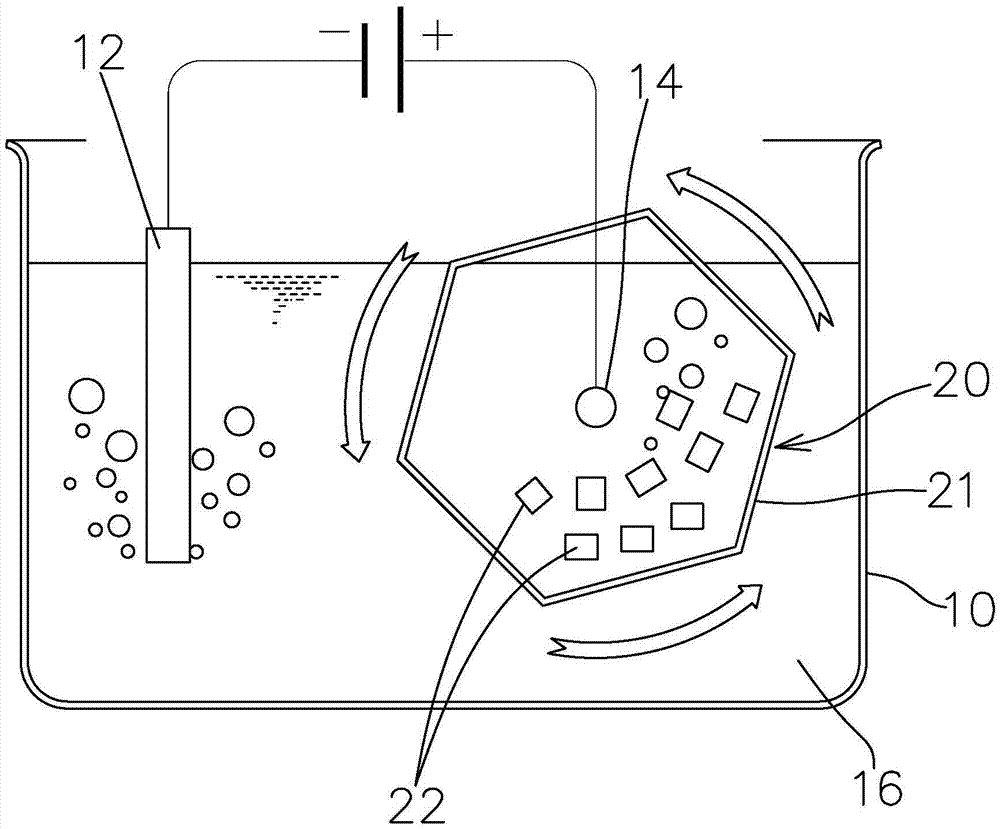

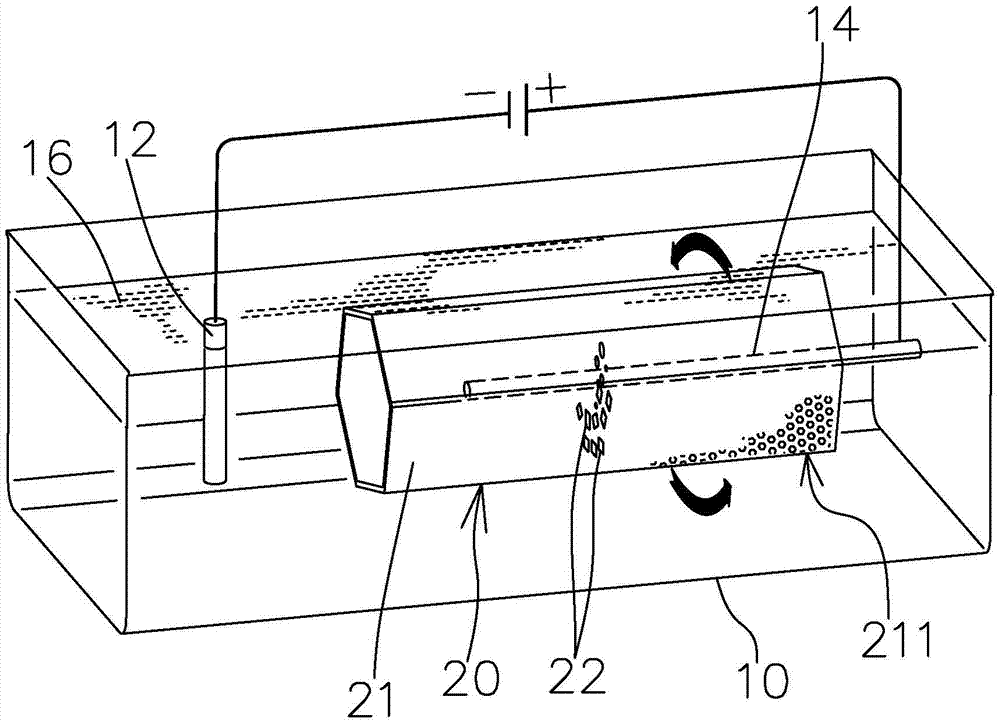

[0027] see figure 2 , image 3 and Figure 4 , which is a preferred embodiment of the graphene mass production equipment and its manufacturing method of the present invention, these drawings are all schematic diagrams for convenience of description, which only schematically illustrate the basic structure of the present invention, and the shown structure The drawing does not limit the same shape and size ratio as the actual implementation, and the actual implementation shape and size ratio is an optional design. As shown in the figure, the graphene mass production equipment of the present invention includes an electrolytic cell 10 and a roller device 20, the electrolytic cell 10 is built with an electrolyte 16 and a first electrode 14, a second electrode 12, the first electrode 14 , The second electrode 12 is immersed in the electrolytic solution 16; wherein, the composition of the electrolytic solution 16 is a solution with an electrolyte, and the electrolyte can include hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com