Packaged phase-change energy-storage composite material with super-high thermal conductivity and processing technology thereof

A technology of phase change energy storage and composite materials, which is applied in the field of organic waxy phase change composite materials and its processing technology, can solve the problems of low thermal conductivity and density of composite materials, expensive composite materials, leakage, etc., and achieve dense blank materials , good application prospects, the effect of low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

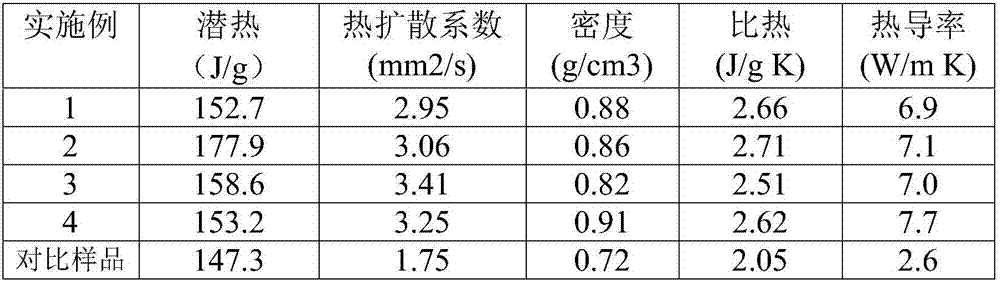

Embodiment 1

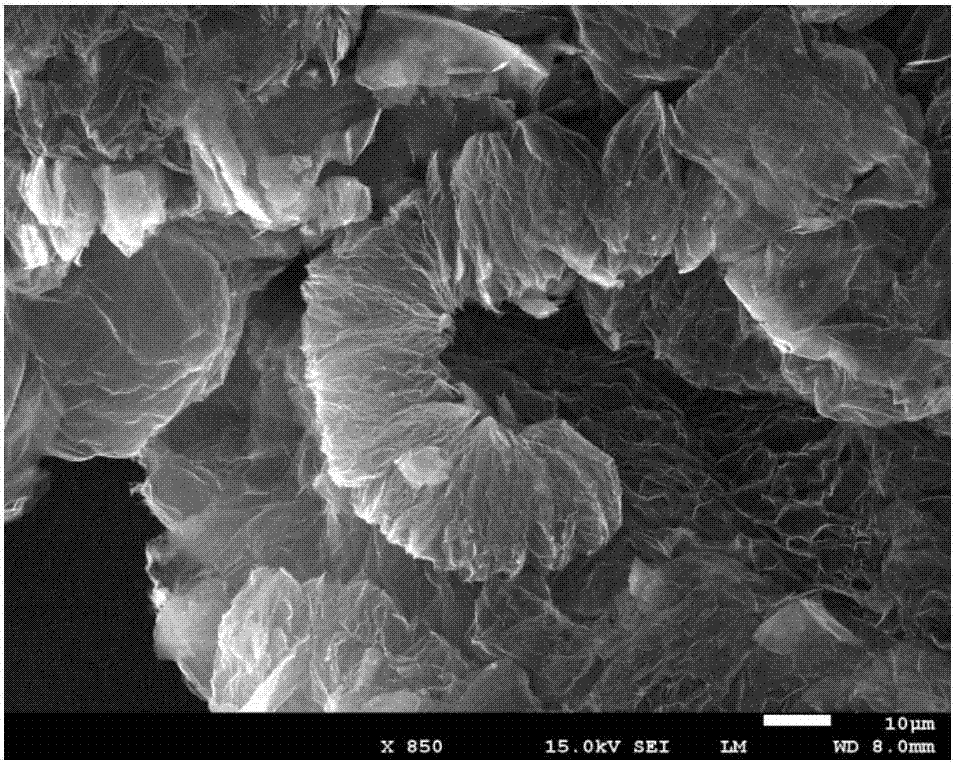

[0031] Example 1: The phase-change energy storage composite material in this example uses n-hexacane as the main material for phase-change energy storage, and its melting temperature is 58°C; expanded graphite and nano-graphene sheets are used as thermal conductivity-enhanced packages; where The expansion temperature of the selected expanded graphite is 950°C, and the expansion rate is about 250 times. According to microscopic analysis, its average pore size is about 2 microns; the selected nano-graphene sheet is a powder material with an average thickness of about 8 nanometers. The ratio is selected as follows: in the overall composite material, the proportion of n-hexacane energy storage material is 90%; the rest is expanded graphite and nano-graphene sheets, wherein the proportion of expanded graphite is 8.5%, and the proportion of nano-graphene sheets is 1.5%.

[0032] The processing technology is as follows: firstly add n-hexacane and expanded graphite material in proporti...

Embodiment 2

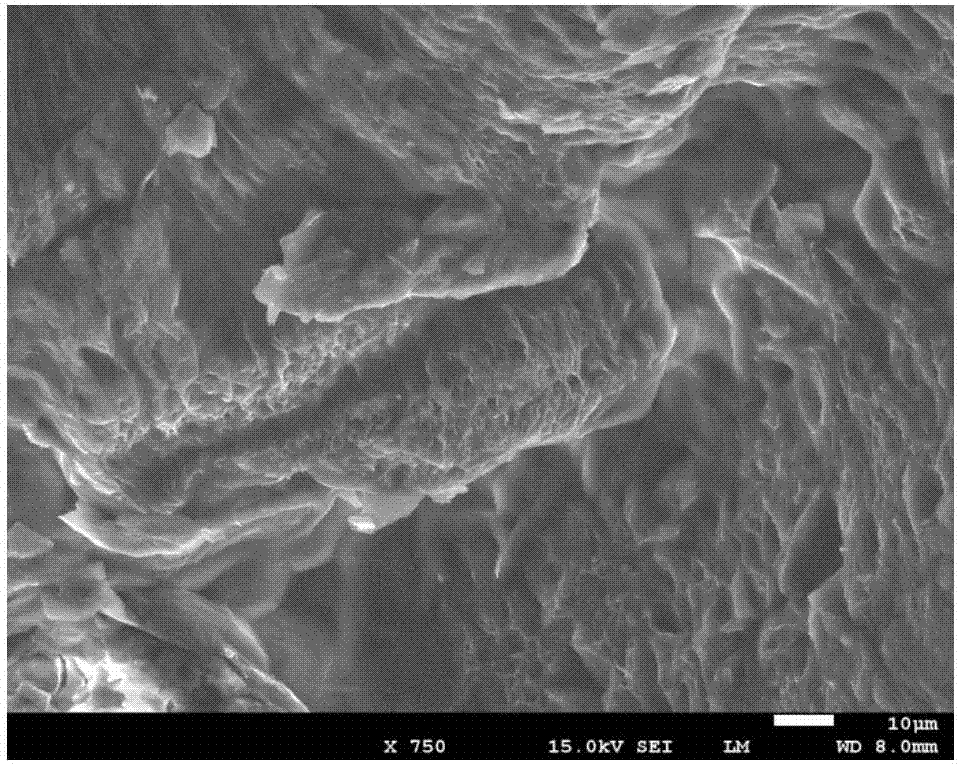

[0033] Example 2: In this example, n-eicosane is selected as the main material for phase change energy storage as the phase change energy storage composite material, and its melting temperature is about 37°C; expanded graphite and nano-graphene sheets are also used as thermal conductivity enhanced packages The expansion temperature of the selected expanded graphite is 900°C, the expansion rate is about 300 times, and the average pore diameter is about 3.5 microns through microscopic analysis; the selected nano-graphene sheet is a powder material with an average thickness of about 10 nanometers. The ratio selection is as follows: in the overall composite material, the proportion of n-eicosane energy storage material is 87%; the rest is expanded graphite and nano-graphene sheets, wherein the proportion of expanded graphite is 11.7%, and the proportion of nano-graphene sheets is 1.3%.

[0034] The processing technology is as follows: first, add n-eicosane and expanded graphite mat...

Embodiment 3

[0035] Example 3: The phase-change energy storage composite material in this example uses n-hexacane as the main material for phase-change energy storage, and its melting temperature is 58°C; expandable graphite and nano-graphene sheets are used as thermal conductivity-enhanced packages The expansion temperature of the selected expanded graphite is 1000°C, and the expansion rate can reach nearly 500 times. According to microscopic analysis and statistics, its average pore size is about 10 microns; the selected nano-graphene sheet is a powder with an average thickness of about 6 nanometers. Material. The ratio is selected as follows: in the overall composite material, the proportion of n-hexacane energy storage material is 94%; the rest is expanded graphite and nano-graphene sheets, wherein the proportion of expanded graphite is 5%, and the proportion of nano-graphene sheets is 1%.

[0036]The processing technology is as follows: firstly add n-hexacane and expanded graphite mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com