Patents

Literature

33results about How to "Reduce stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

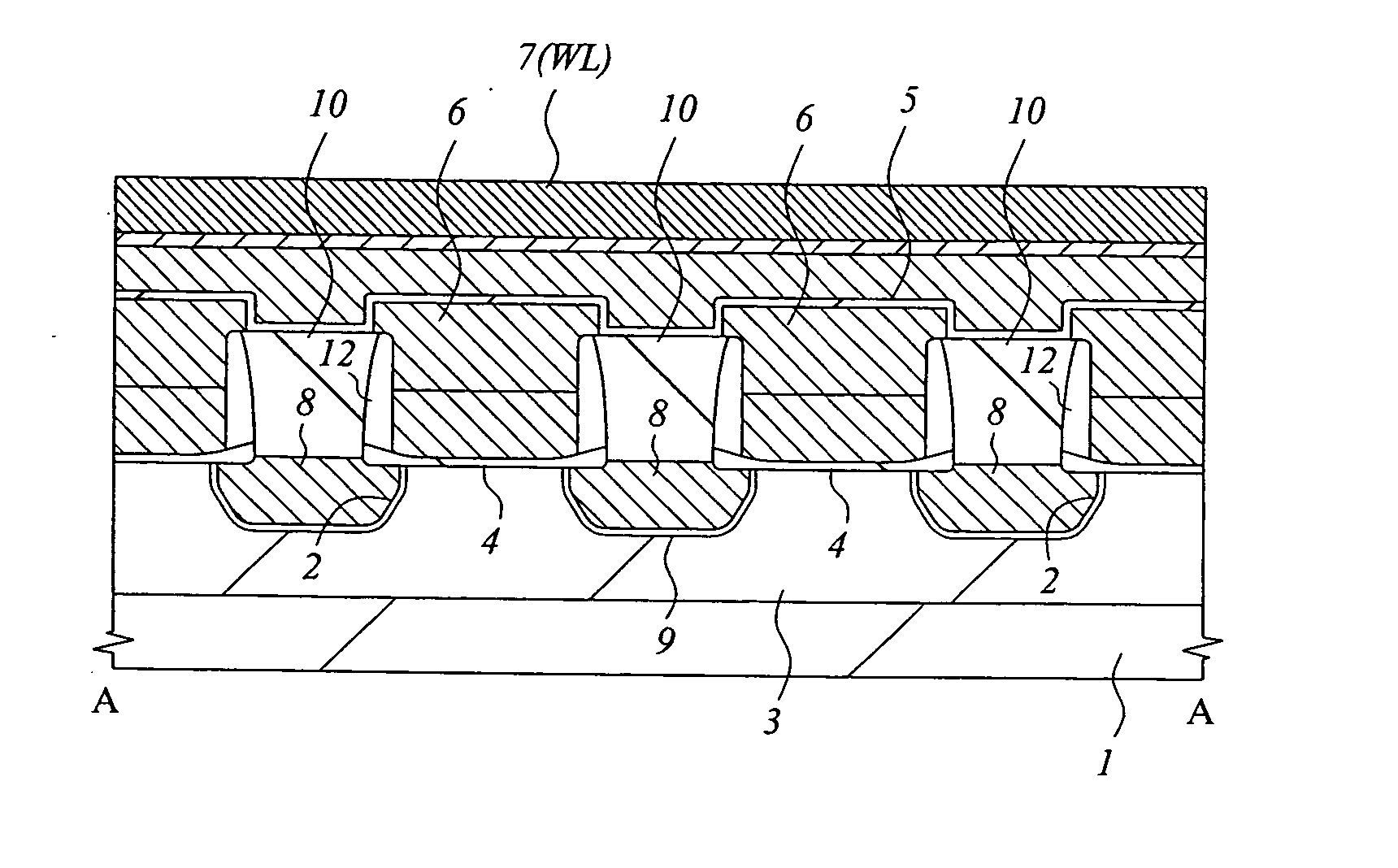

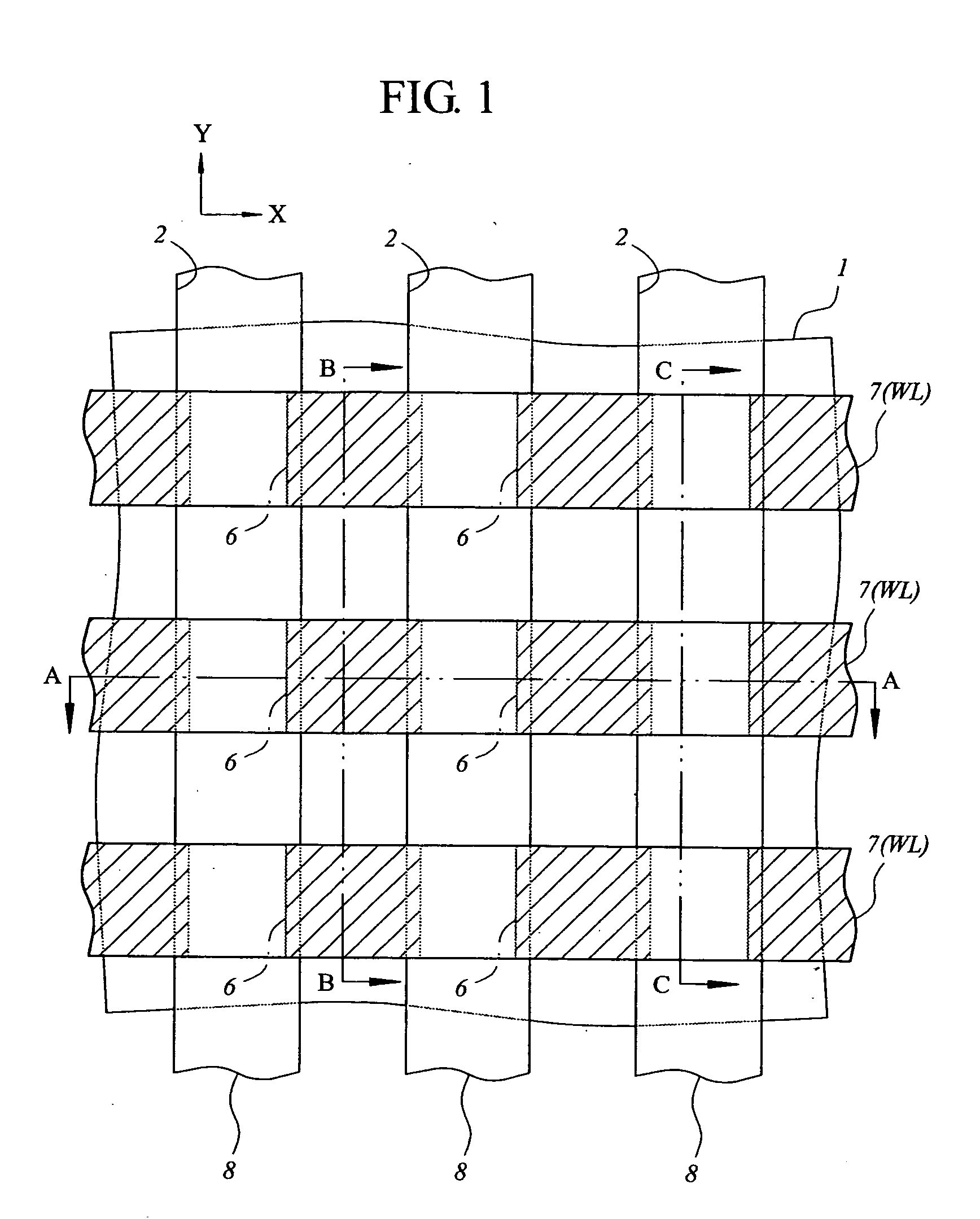

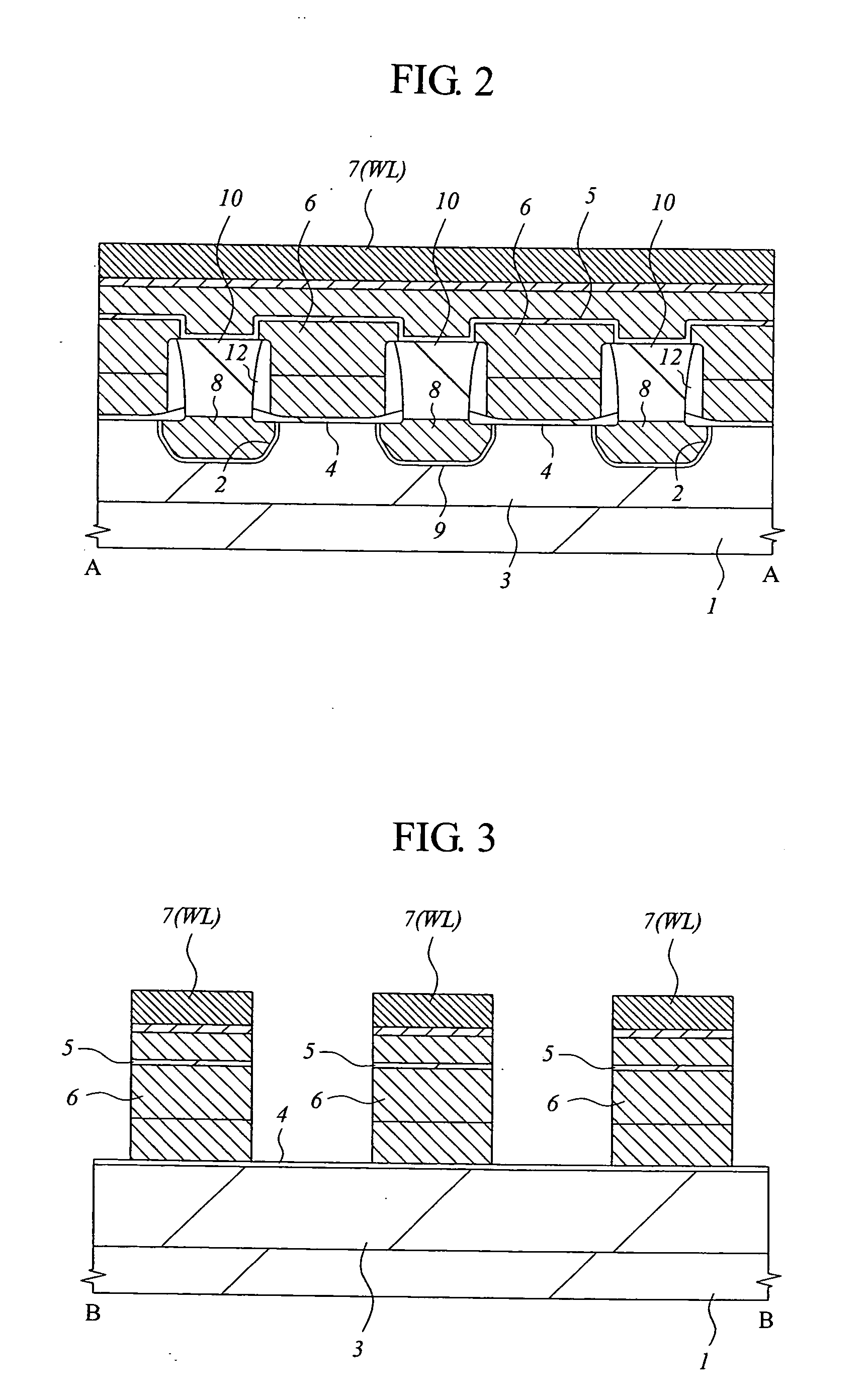

Nonvolatile semiconductor memory device and manufacturing method thereof

InactiveUS20050062096A1Ensuring reading speedReduce stampingTransistorSolid-state devicesGate insulatorSilicon oxide

A nonvolatile semiconductor memory device, in which an inversion layer formed over a semiconductor substrate is used as a data line, is achieved with its high integration and high performance. A memory cell is composed of a MOS transistor having a floating gate, a control gate constituting a word line, and a buried gate. The buried gate is buried in a groove formed in a self-alignment manner with respect to the floating gate. The buried gate and the control gate disposed over it are isolated from each other by a thick silicon oxide film on the groove and a second gate insulator film formed thereon. A source and drain of the memory cell are composed of an inversion layer (local data line) formed on a p type well disposed below the buried gate when a positive voltage is applied to the buried gate.

Owner:RENESAS TECH CORP

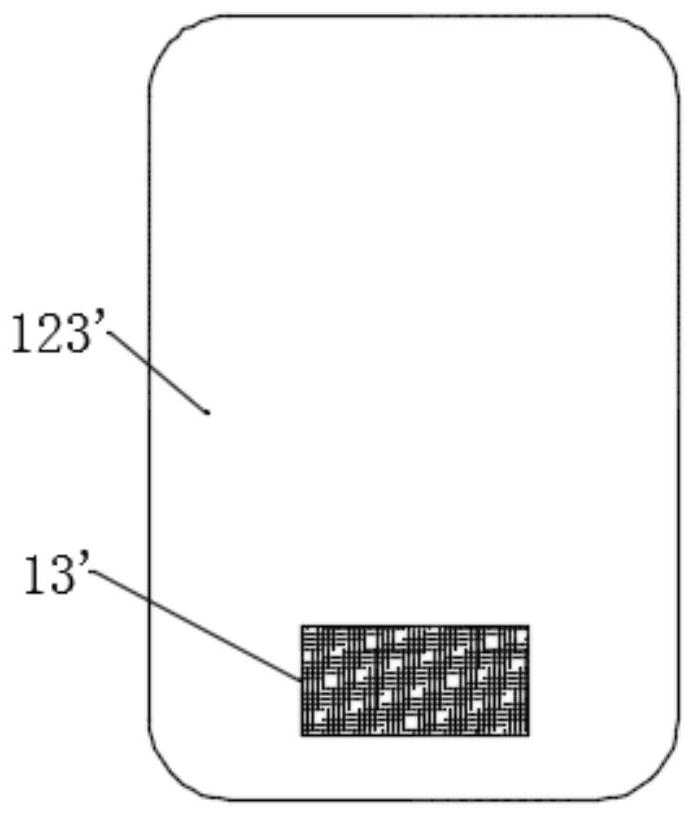

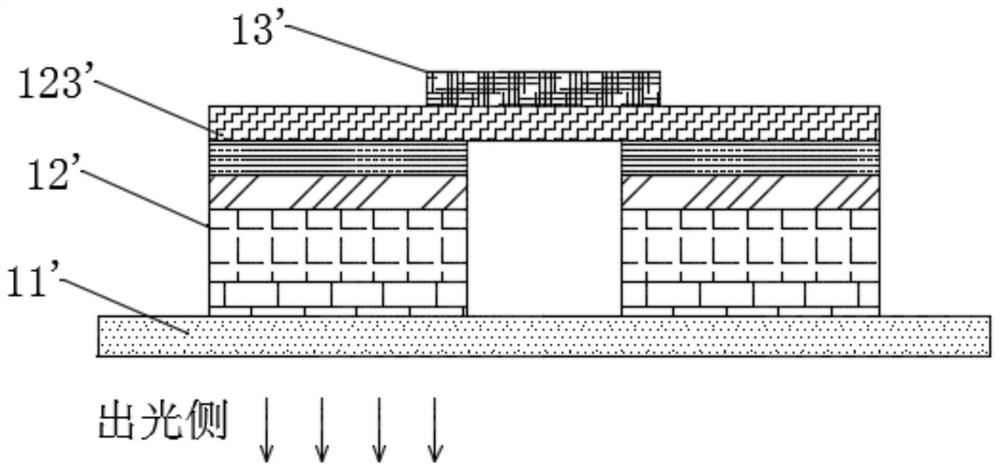

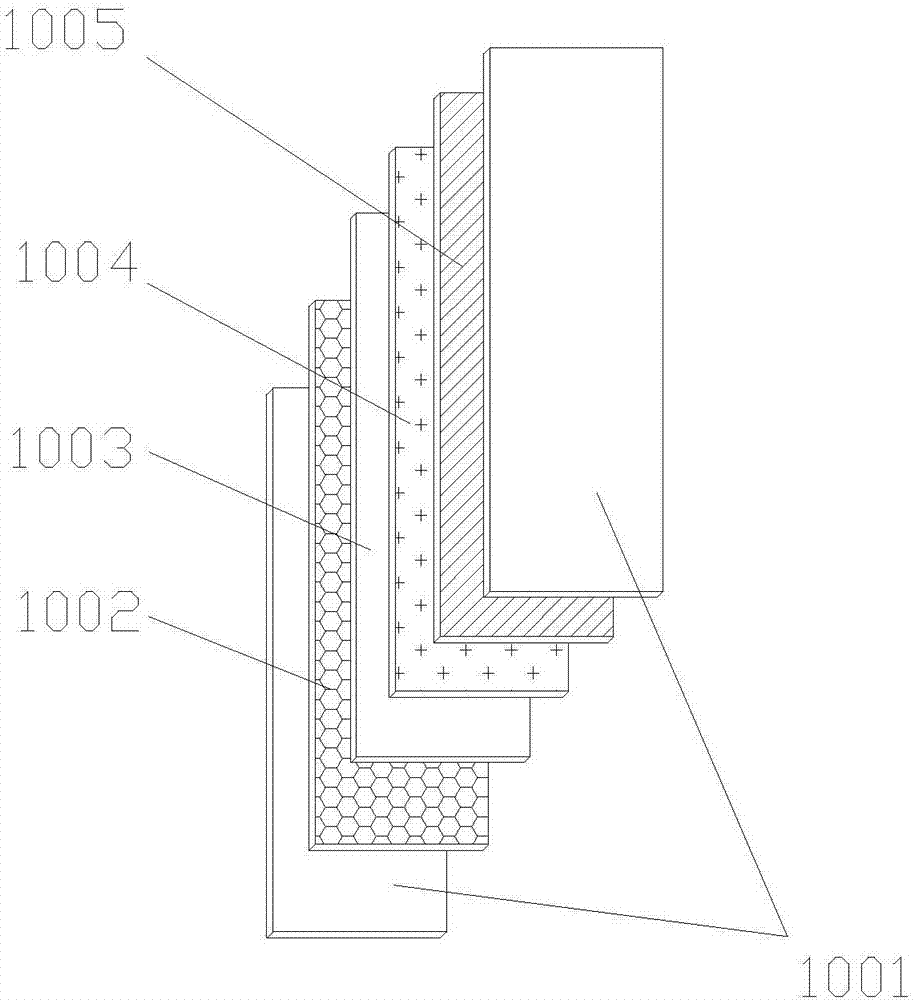

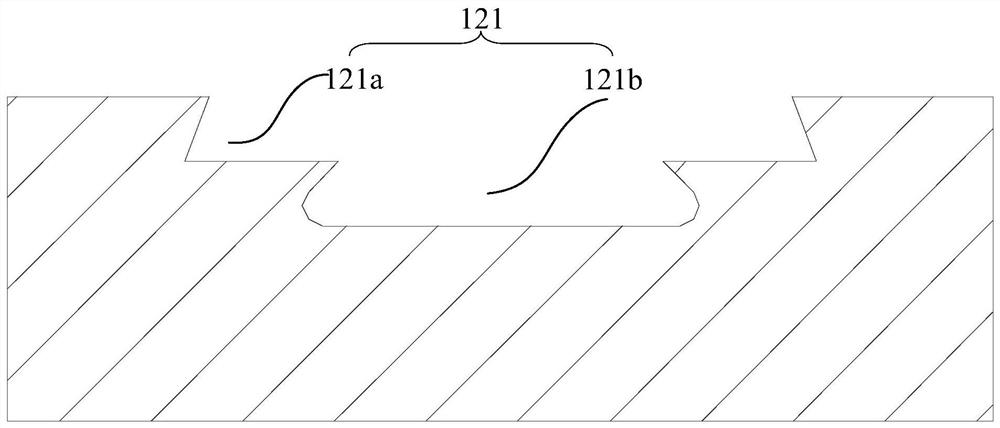

Flexible display module, under-screen fingerprint display device and manufacturing method

PendingCN111785175AReduce stressEliminate gapsCharacter and pattern recognitionCooling/ventilation/heating modificationsAdhesive beltDisplay device

The invention discloses a flexible display module, an under-screen fingerprint display device and a manufacturing method. The flexible display module comprises a display panel, a heat dissipation filmand a shading adhesive tape, wherein the heat dissipation film comprises a first film layer, a second film layer and a protective film layer which are sequentially stacked on the side, away from thelight emitting side, of the display panel, the first film layer comprises a first open hole penetrating through the first film layer, and the first open hole corresponds to a sensing area of a fingerprint recognition module to be installed of the flexible display module; the second film layer comprises a second open pore penetrating through the second film layer, the second open pore and the firstopen pore are correspondingly arranged to expose the induction area of the fingerprint recognition module to be installed, and the aperture of the second open pore is larger than that of the first open pore; the protective film covers the second film layer; the shading adhesive tape is arranged on the side, close to the display panel, of the protective film layer and located in the second open hole, and the orthographic projection of the shading adhesive tape on the display panel covers the orthographic projection of the first open hole on the display panel. According to the invention, the mold marks at the opening of the display panel can be effectively reduced.

Owner:BOE TECH GRP CO LTD +1

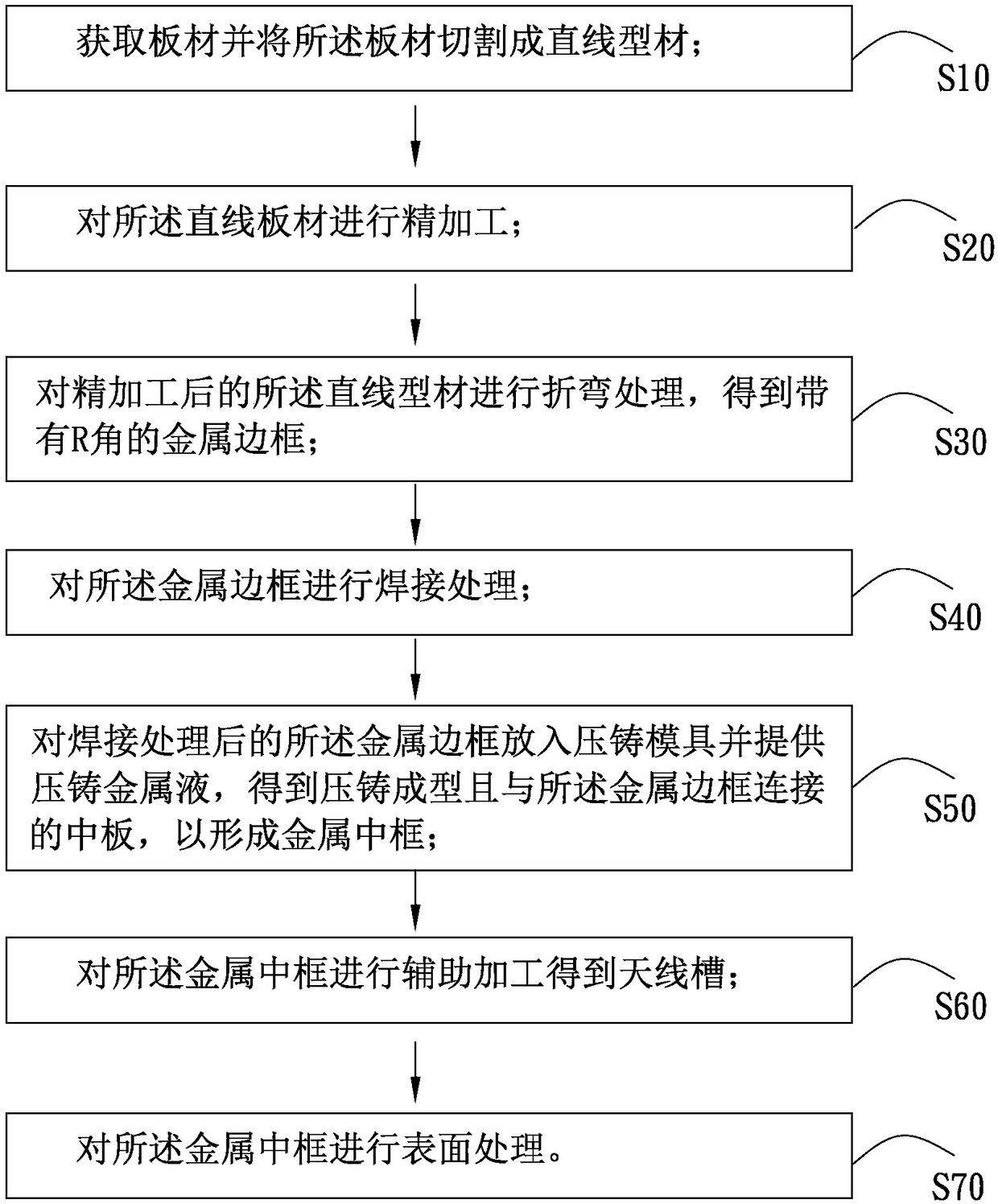

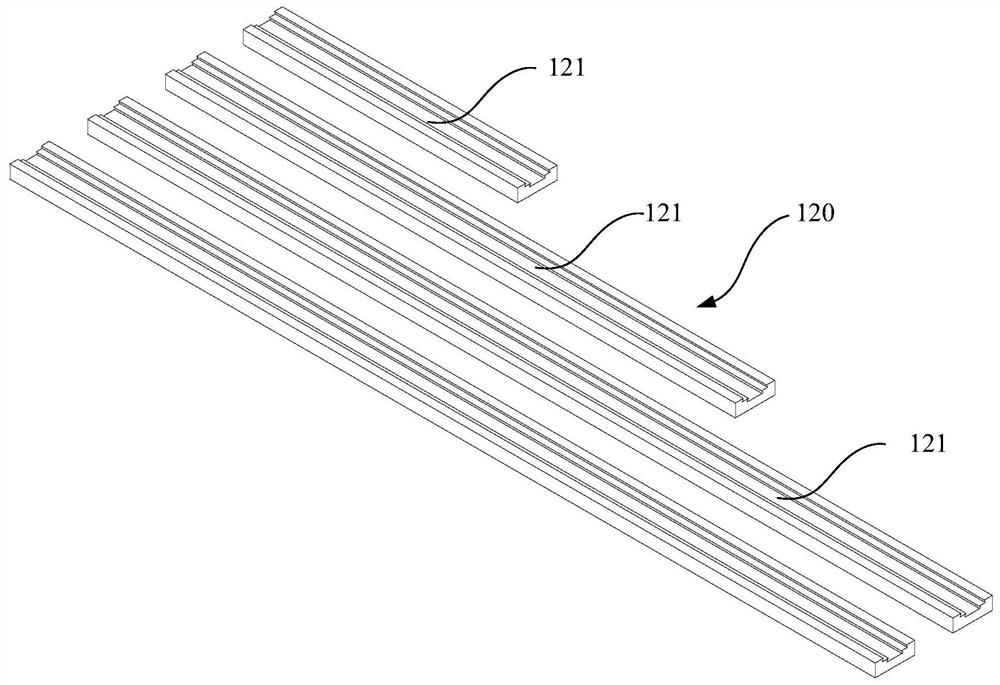

Metal middle frame machining process

InactiveCN108296709AReduce processing timeIncrease productivitySubstation equipmentElectrical apparatus casings/cabinets/drawersDie castingMachining process

The invention relates to a metal middle frame machining process. The metal middle frame machining process comprises the following steps of: obtaining a plate and cutting the plate into a linear section; carrying out finish machining on the linear section; bending the linear section after the finish machining so as to obtain a metal frame with an R angle; welding the metal frame; putting the weldedmetal frame into a die-casting die, and providing die-casting molten metal to obtain a middle plate which is die-cast formed and connected with the metal frame so as to form a metal middle frame. According to the metal middle frame machining process, the metal middle frame adopts a process of bending, welding and die-cast forming, so that material waste caused by metal frame machining margin is decreased, and the proportion of raw material cost in total manufacture cost is reduced. Meanwhile, procedures of middle stamping, CNC machining and hot processing are decreased, the machining time ofthe metal middle frame is shortened and then the production efficiency of the whole metal middle frame is improved.

Owner:GUANGDONG EVERWIN PRECISION TECH

Environment-friendly plate cutting device

InactiveCN106003189AReduce stampingAvoid crackingDirt cleaningMetal working apparatusEngineeringMechanical engineering

The invention discloses an environment-friendly plate cutting device, which comprises a main body, a cutting cavity is formed in the main body along the conveying direction of the plate, a cutting groove is formed downward along the bottom of the cutting cavity along the vertical direction, and a knife is arranged on the top of the main body The head assembly is used to fix the cutter head and the cutter head assembly can move along the vertical direction to extend the cutter head into the cutting cavity; the bottoms of the two ends of the cutter head assembly horizontally extend outward with ear blocks, and the ear blocks are formed with vertically extending and a guide rod is arranged in the through hole, a pressing block is formed on the bottom of the guiding rod and a compression spring is arranged between the pressing block and the bottom of the ear block; the environmental-friendly plate cutting device also includes a dust removal mechanism, and the dust removal The mechanism can be communicated with the cutting cavity to suck the dust in the cutting cavity. The environment-friendly board cutting device can cut boards excellently.

Owner:芜湖昊轩环保新材料有限公司

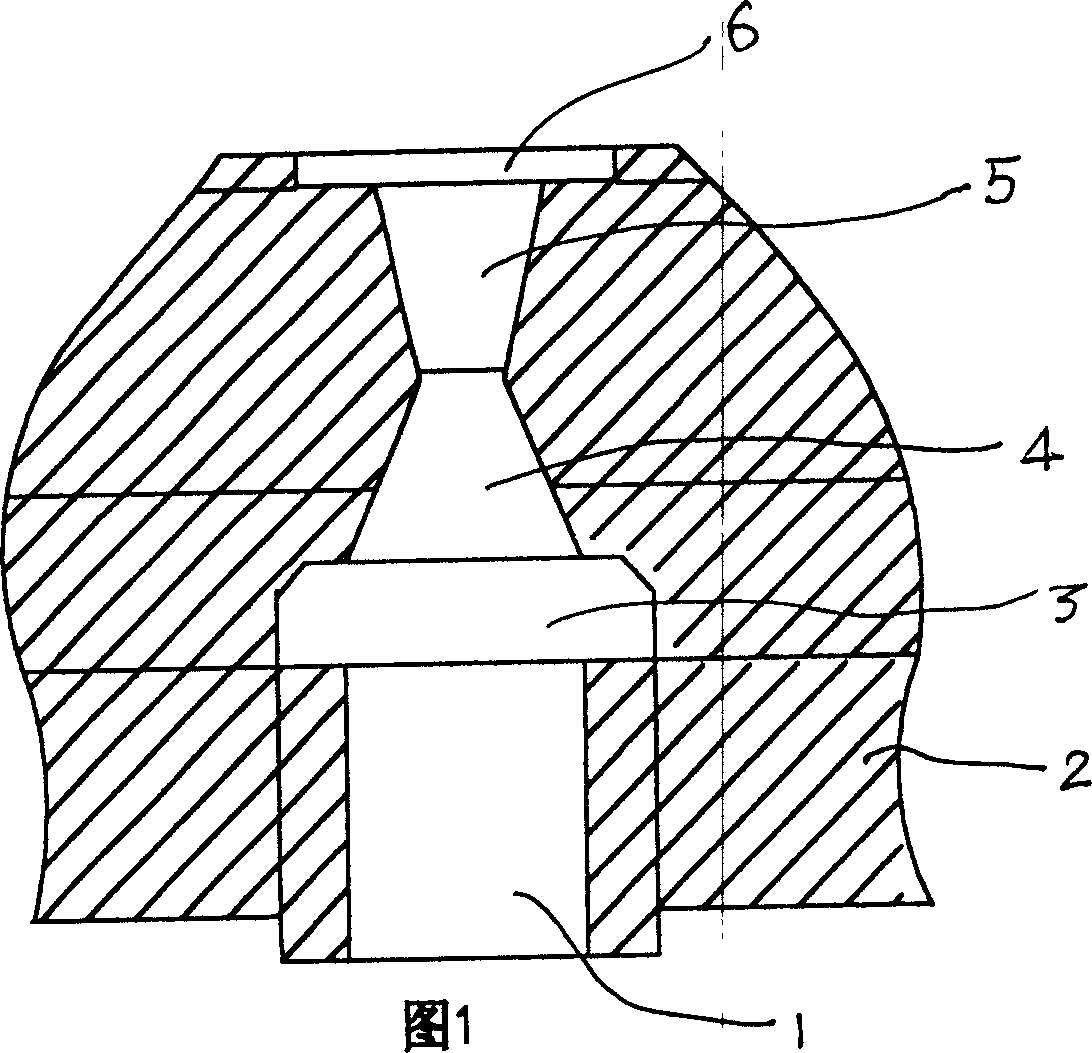

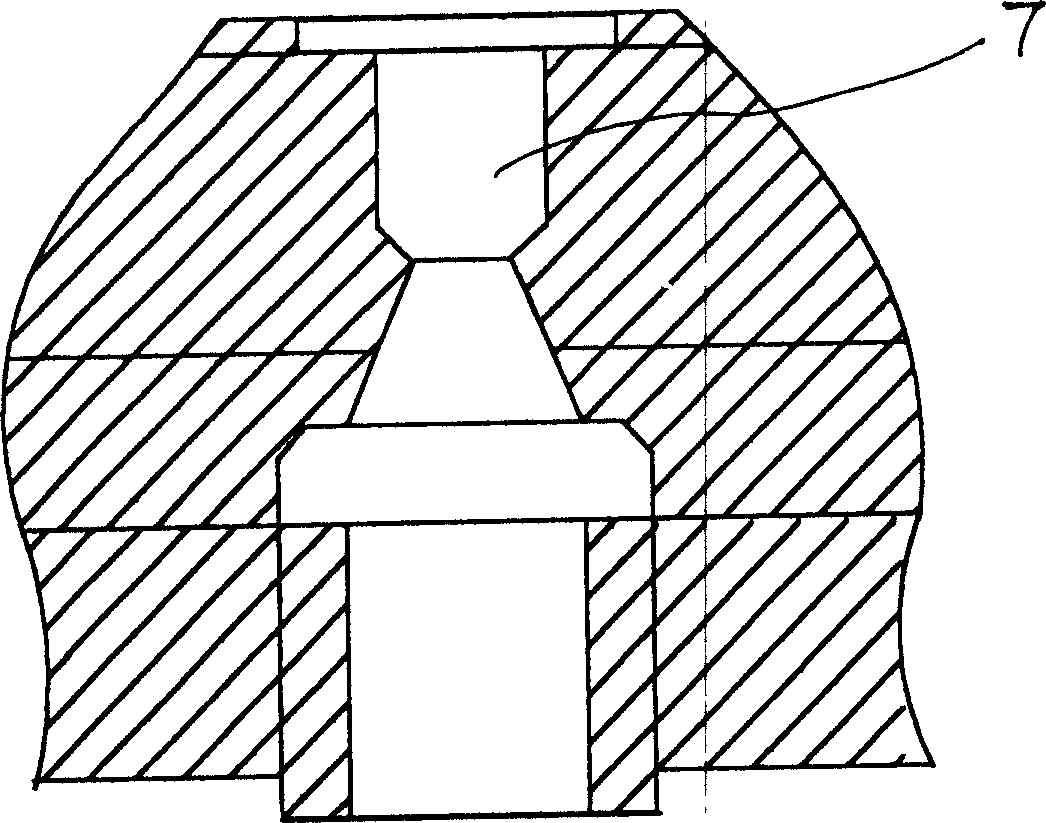

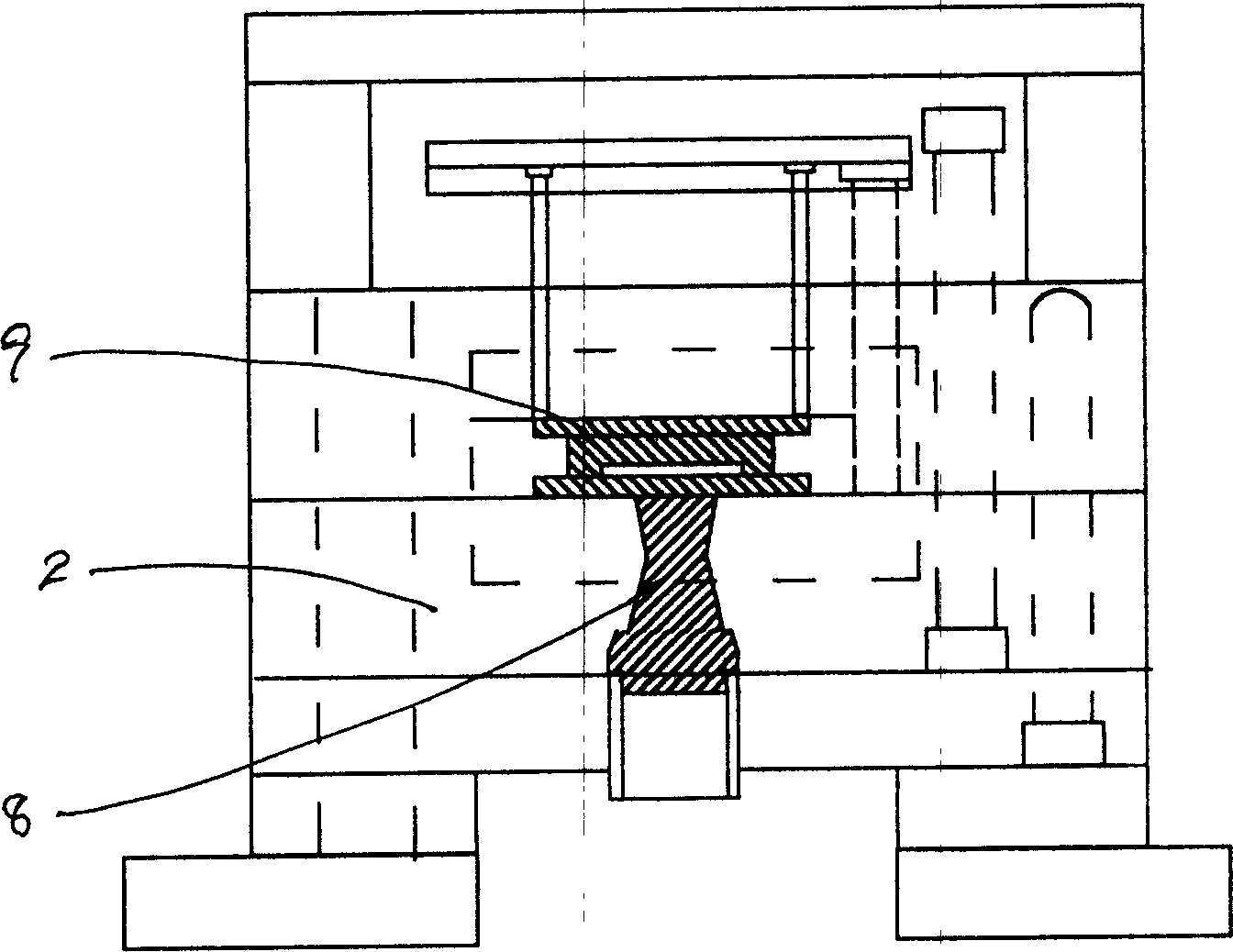

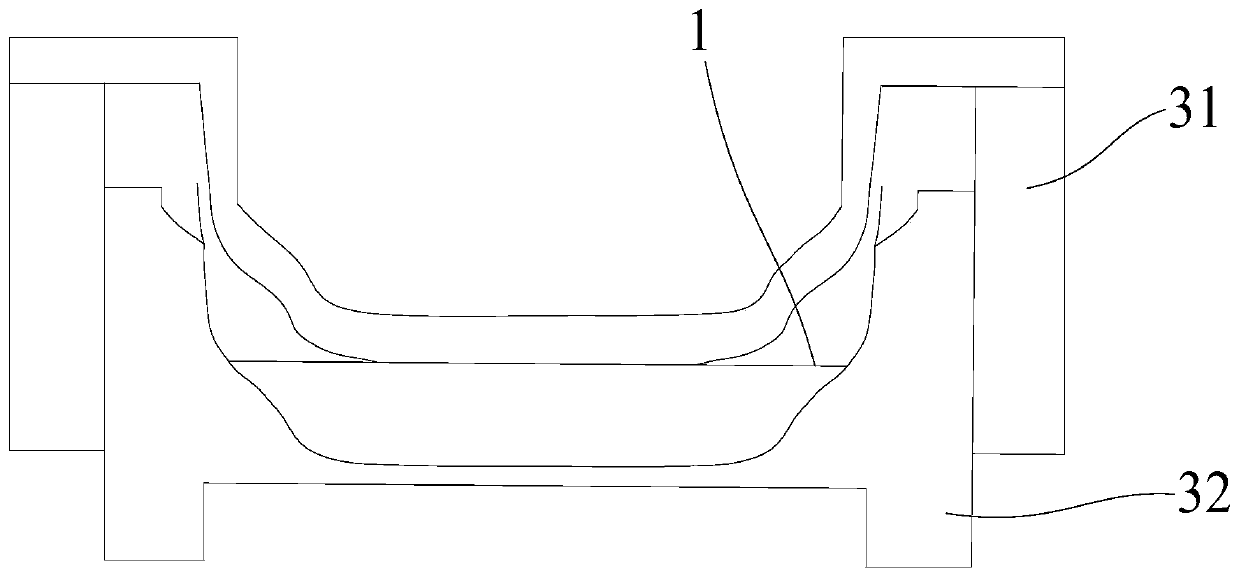

Central running-gate mould cavity of extruding mould

A central sprue cavity of pressig die is composed of raw material staying tray, sprue cup, and internal sprue consisting of upper segment whose cross-section is gradually decreased and lower segment whose cross-section is gradually increased. Its advantages are low pressure to die and die locking force, and easy breaking off of prue on demoulding.

Owner:象山昌盛汽车空调模具厂

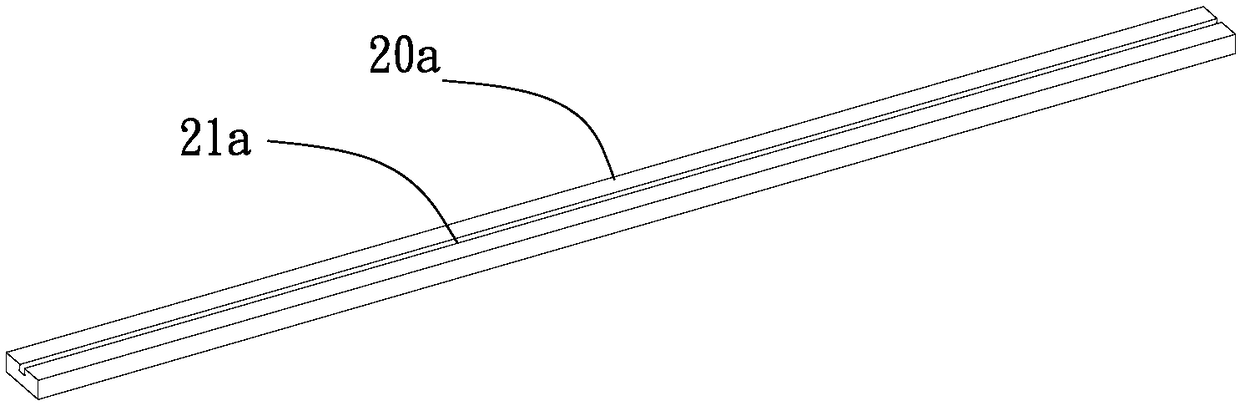

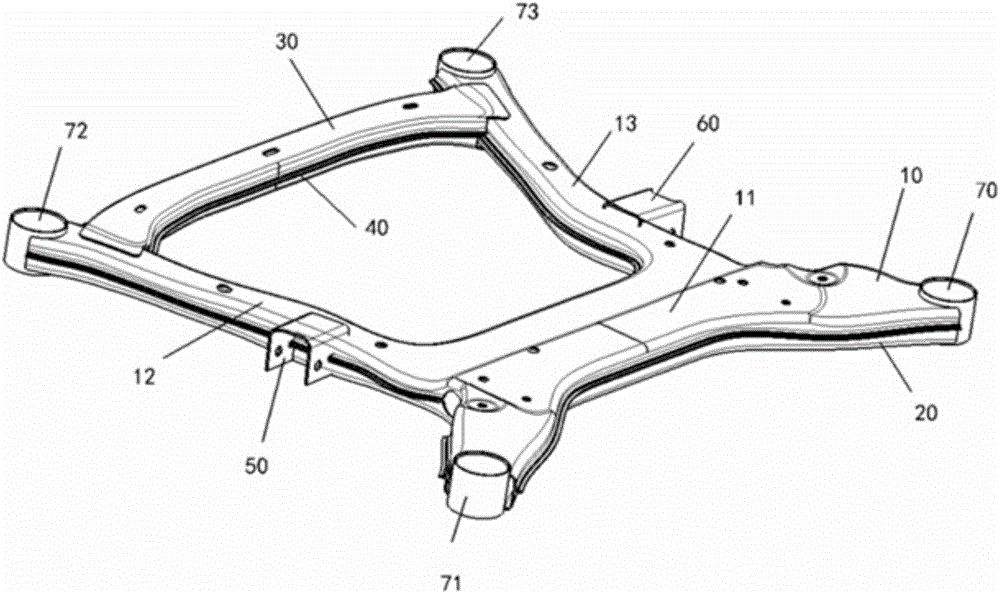

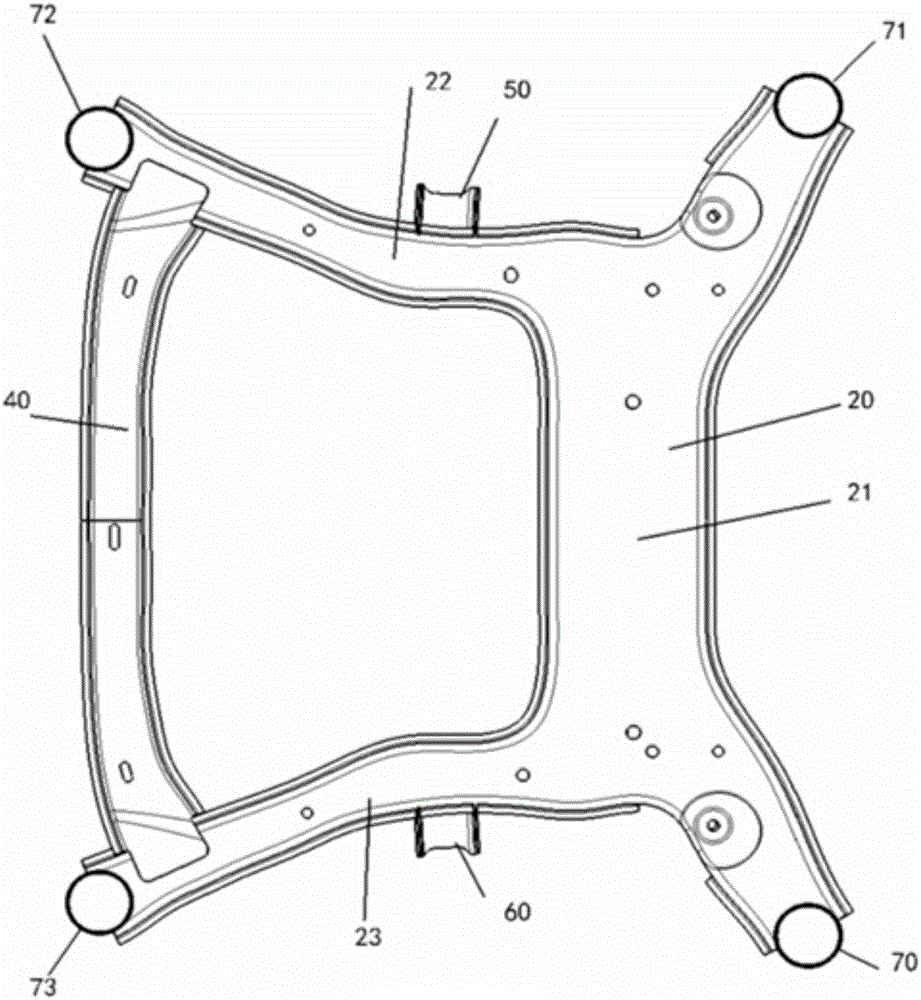

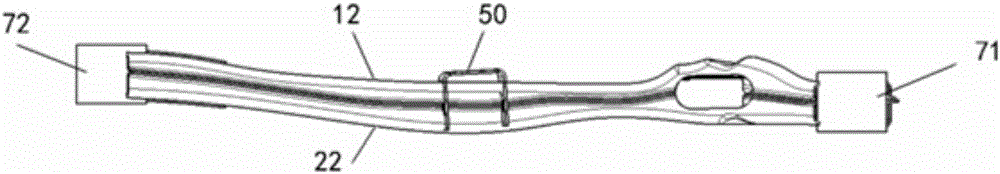

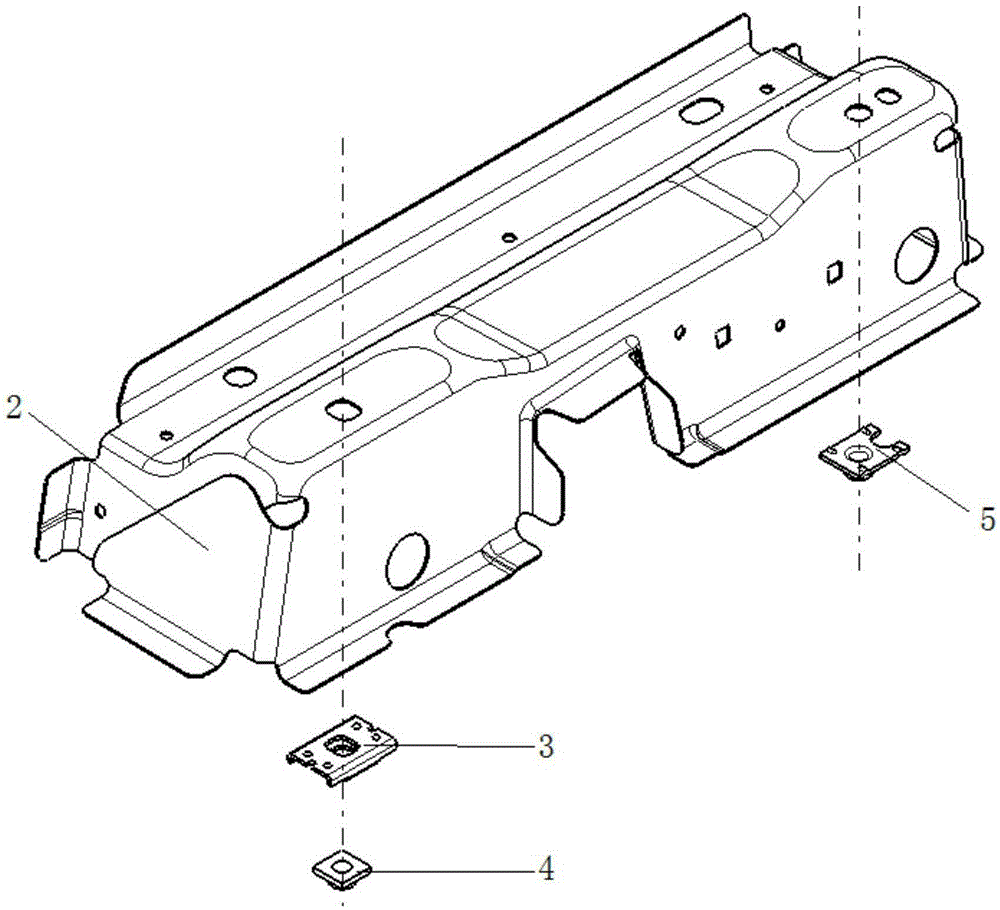

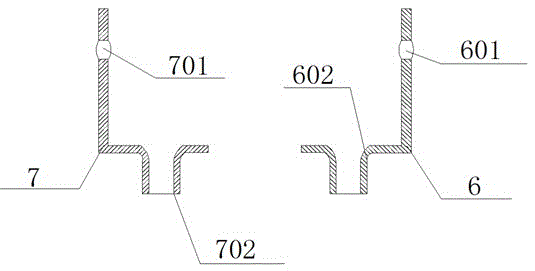

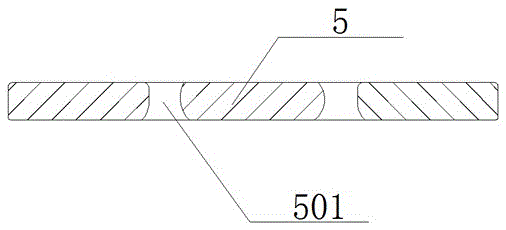

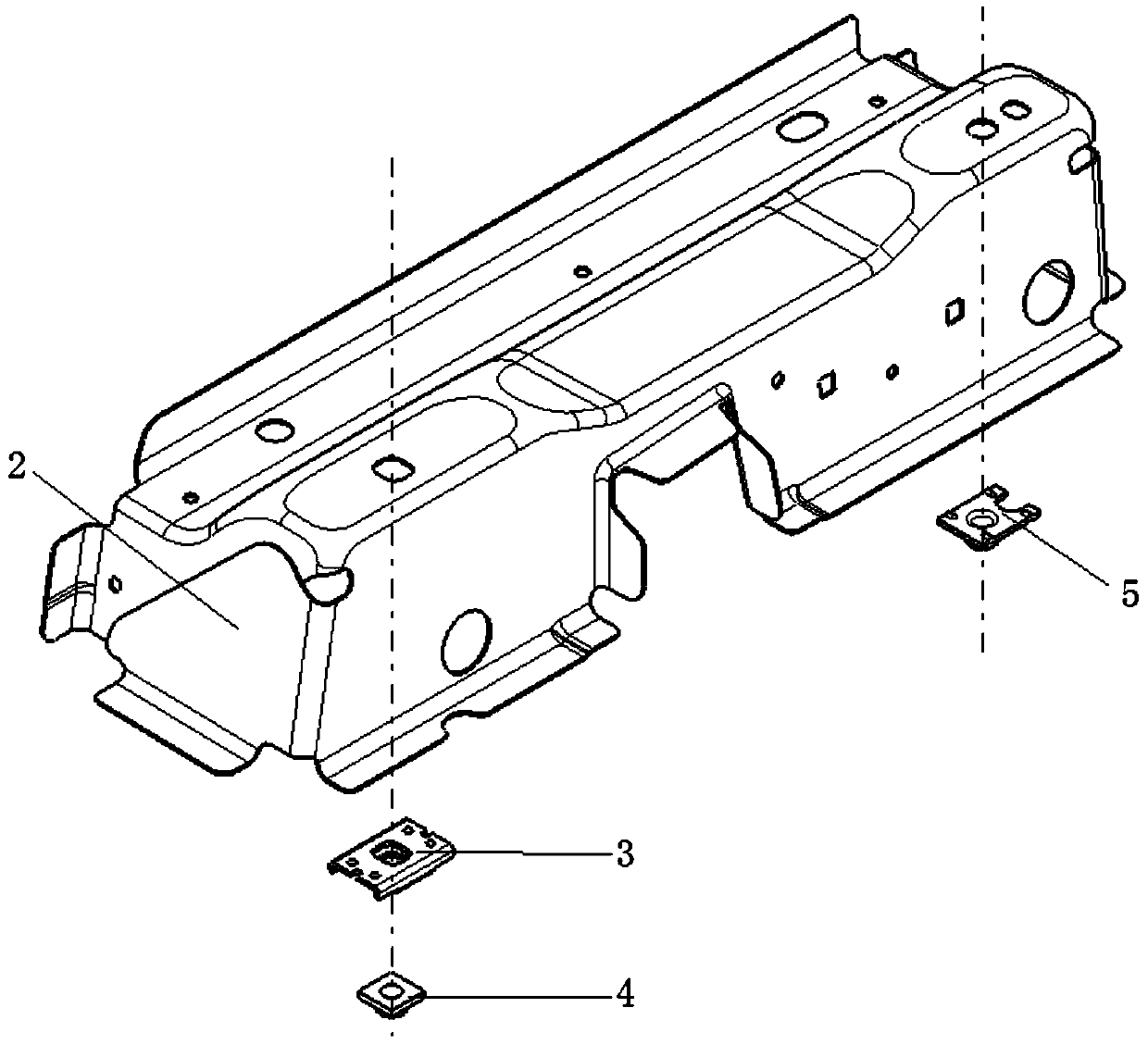

Electric automobile subframe

PendingCN106809278AReduce in quantitySufficient strength and rigidityUnderstructuresVehicle frameControl arm

The invention relates to an electric automobile subframe. The electric automobile subframe includes a main beam upper sheet (10), a main beam lower sheet (20), a front cross beam upper sheet (30) and a front cross beam lower sheet (40); the front cross beam upper sheet (30) and the front cross beam lower sheet (40) are of --shaped frame structures; the front cross beam upper sheet (30) and the front cross beam lower sheet (40) are welded into a front cross beam; the main beam upper sheet (10) and the main beam lower sheet (20) are of U-shaped frame structures, and the main beam upper sheet (10) and the main beam lower sheet (20) are welded into a main beam; a left control arm installation support (50) and a right control arm installation support (60) are welded to the left side and the right side of the main beam respectively; and the front cross beam and the main beam are welded into a sealed frame structure, and automobile body installation lining casing tubes (70) are welded to four corners of the sealed frame structure. The electric automobile subframe has a small number of stamping parts under the premise of meeting a design demand, can reduce the stamping and welding processes, can reduce the cost, and can improve the production efficiency.

Owner:MAGNA STEYR AUTOMOTIVE TECHNOLOGY (SHANGHAI) LTD

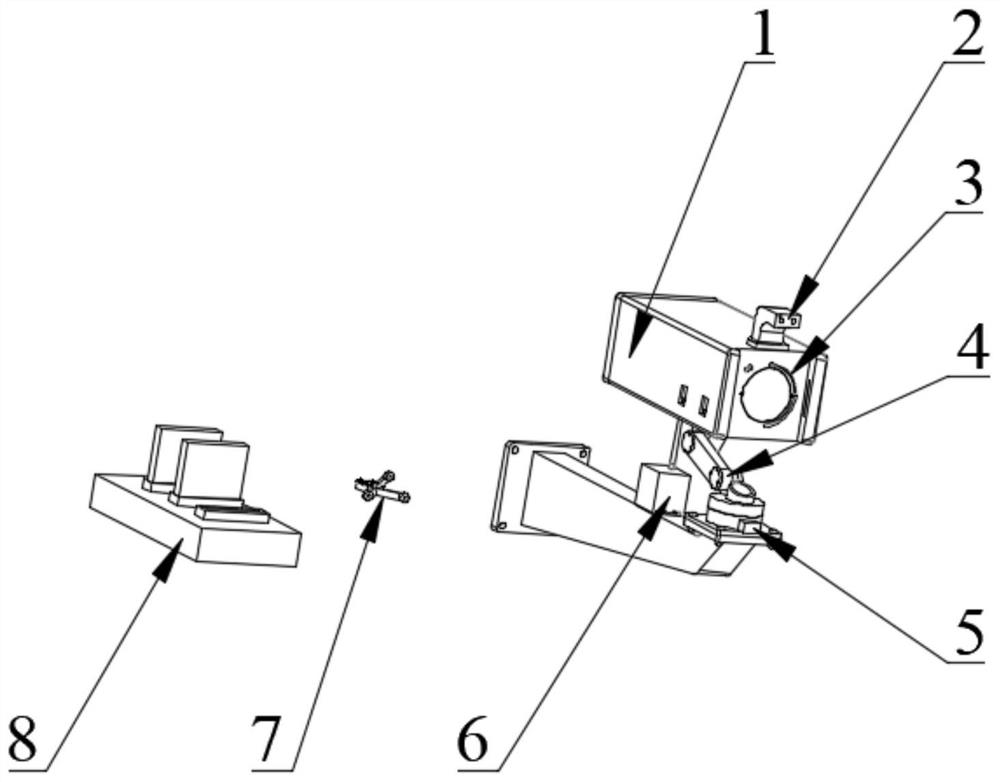

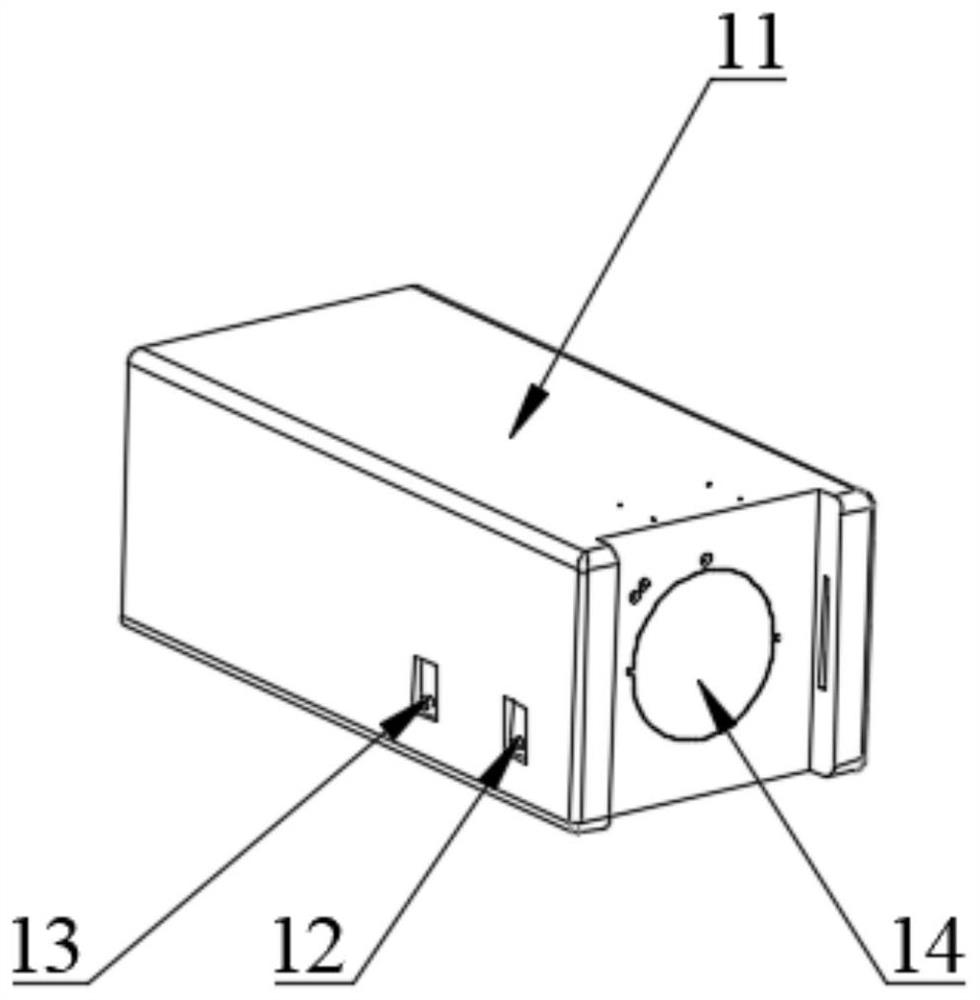

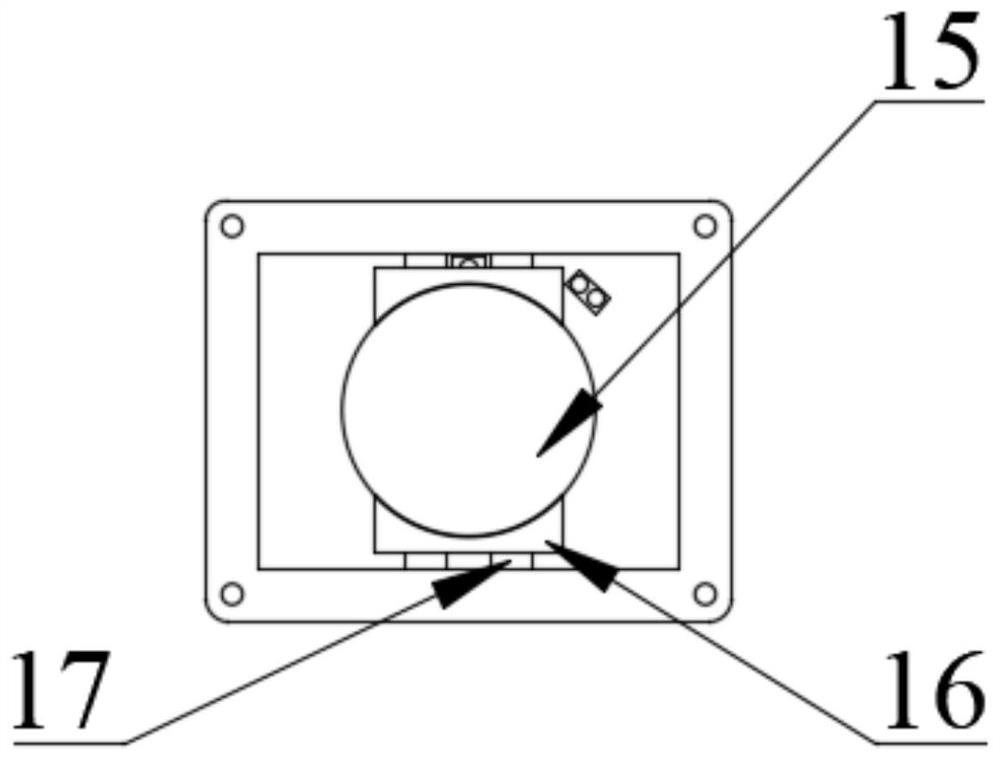

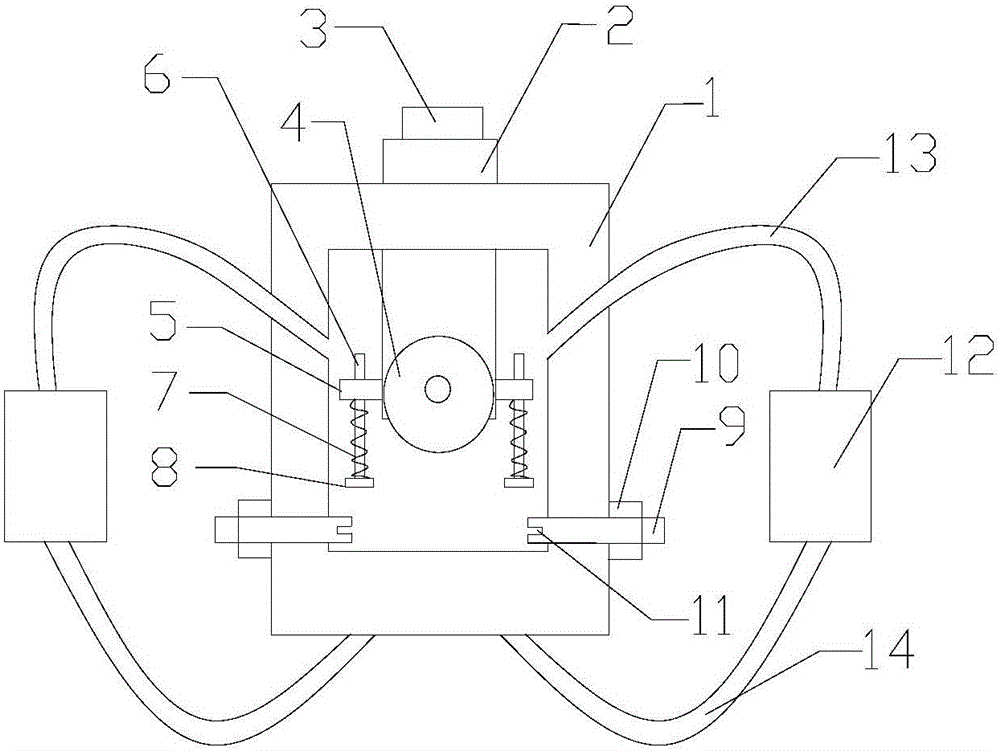

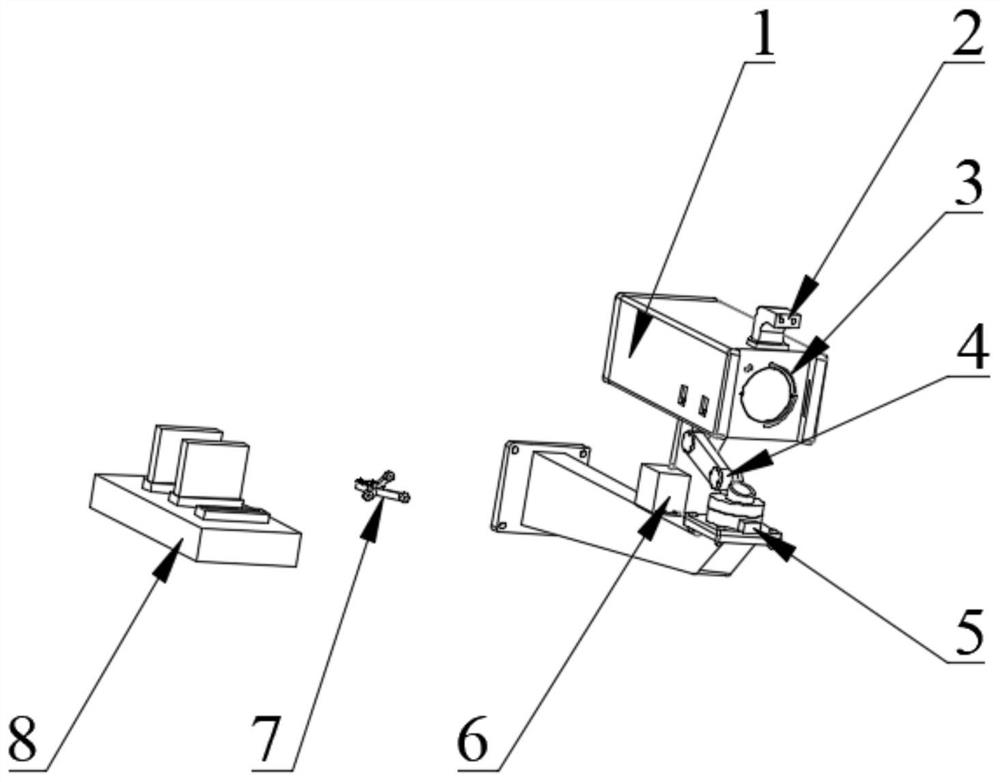

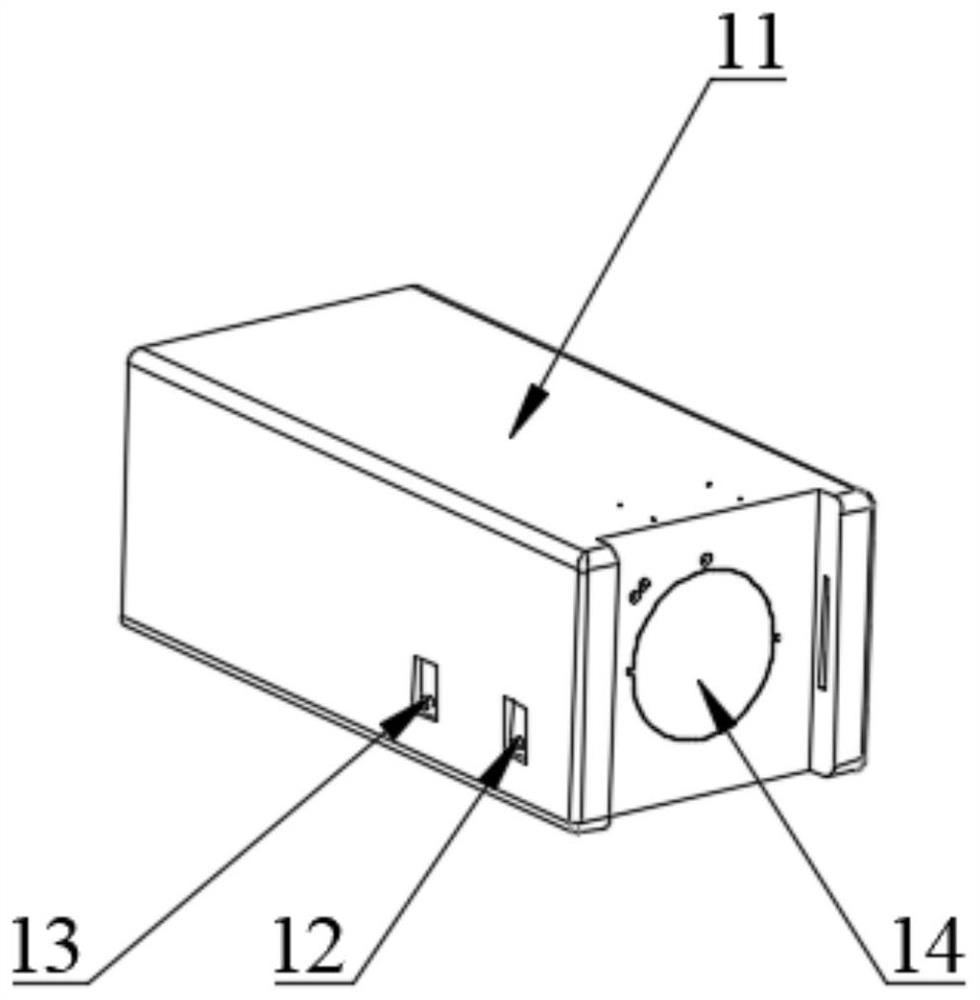

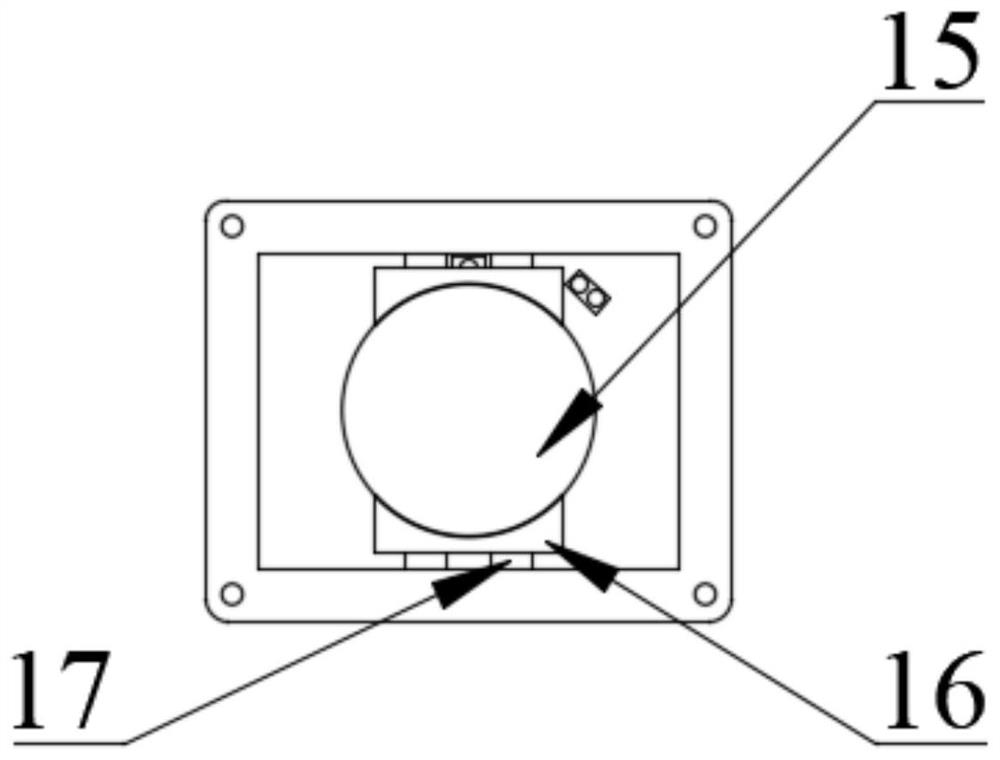

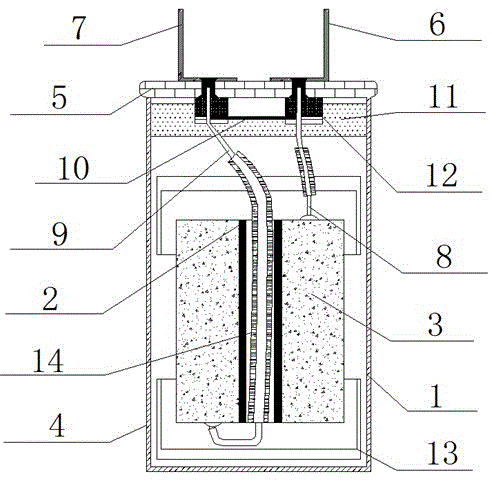

Underground coal mine video monitoring system capable of automatically charging and cleaning a mirror surface and application thereof

ActiveCN112738479AStable jobLittle outside influenceTelevision system detailsColor television detailsVideo monitoringDust control

The invention discloses an underground coal mine video monitoring system capable of automatically charging and cleaning a mirror surface and application thereof, and the underground coal mine video monitoring system comprises a protection device, a lighting device, a cleaning device, a lifting device, a control device, an air blowing device, a grabbing device and an energy device. Intelligent operation of the video monitoring system is realized by using the control device, the protection device can achieve overall corrosion prevention and explosion prevention, the camera body part is internally arranged, the lighting device can be automatically turned on and turned off to ensure that video monitoring pictures are clear and bright, and an atomizer and a scraping brush in the cleaning device are used for cleaning a lens to avoid excessive dust influences. The lifting device achieves up-down movement and 360-degree rotation of dynamic video monitoring under the action of the control device, an air blower in the air blowing device conducts dust removal and blow-drying on a lens through an explosion-proof hose under the action of the control device, and the grabbing device achieves replacement of a rechargeable battery through a flying mechanical arm. A charging base station in the energy device is used for storing a standby rechargeable battery so as to ensure long-term stable operation of the video monitoring system.

Owner:SHANDONG UNIV OF SCI & TECH

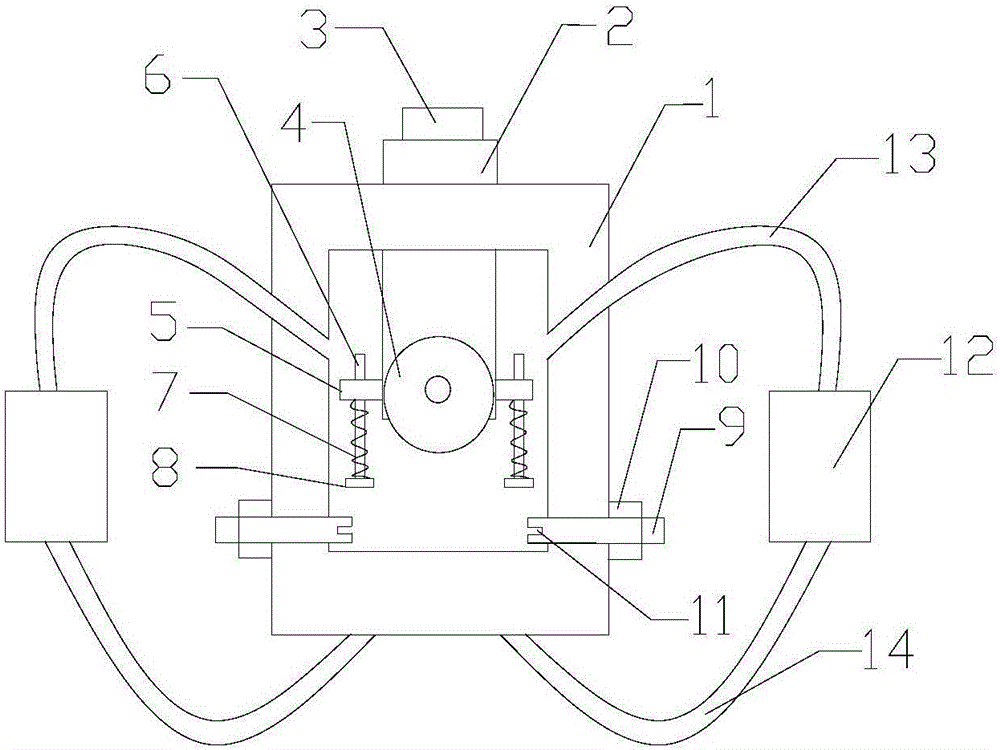

Guide type plate cutting device

InactiveCN106078836AReduce stampingAvoid crackingDirt cleaningMetal working apparatusMechanical engineeringEngineering

The invention discloses a guide type plate cutting device which comprises a main body. A cutting cavity is formed in the main body in the conveying direction of a plate. The bottom of the cutting cavity is provided with a cutting groove downwards in the vertical direction. The top of the main body is provided with a tool bit assembly for fixing a tool bit, and the tool bit assembly can move in the vertical direction so that the tool bit can extend into the cutting cavity. The bottoms of the two ends of the tool bit assembly horizontally extend outwards to form lugs. Each lug is provided with a through hole which extends vertically, a guide rod is arranged in each through hole, the bottom of each guide rod is provided with a pressing block, and a compressed spring is arranged between each pressing block and the bottom of the corresponding lug. The guide type plate cutting device further comprises a feeding guide mechanism. The feeding guide mechanism is located in front of the main body in the plate conveying direction, and the feeding guide mechanism can give clamping force to the plate in the horizontal direction. The feeding guide mechanism comprises a base and two L-shaped clamping plates. The two L-shaped clamping plates are symmetrically arranged at the two ends of the top of the base so as to clamp the plate. The guide type plate cutting device can excellently cut the plate.

Owner:芜湖昊轩环保新材料有限公司

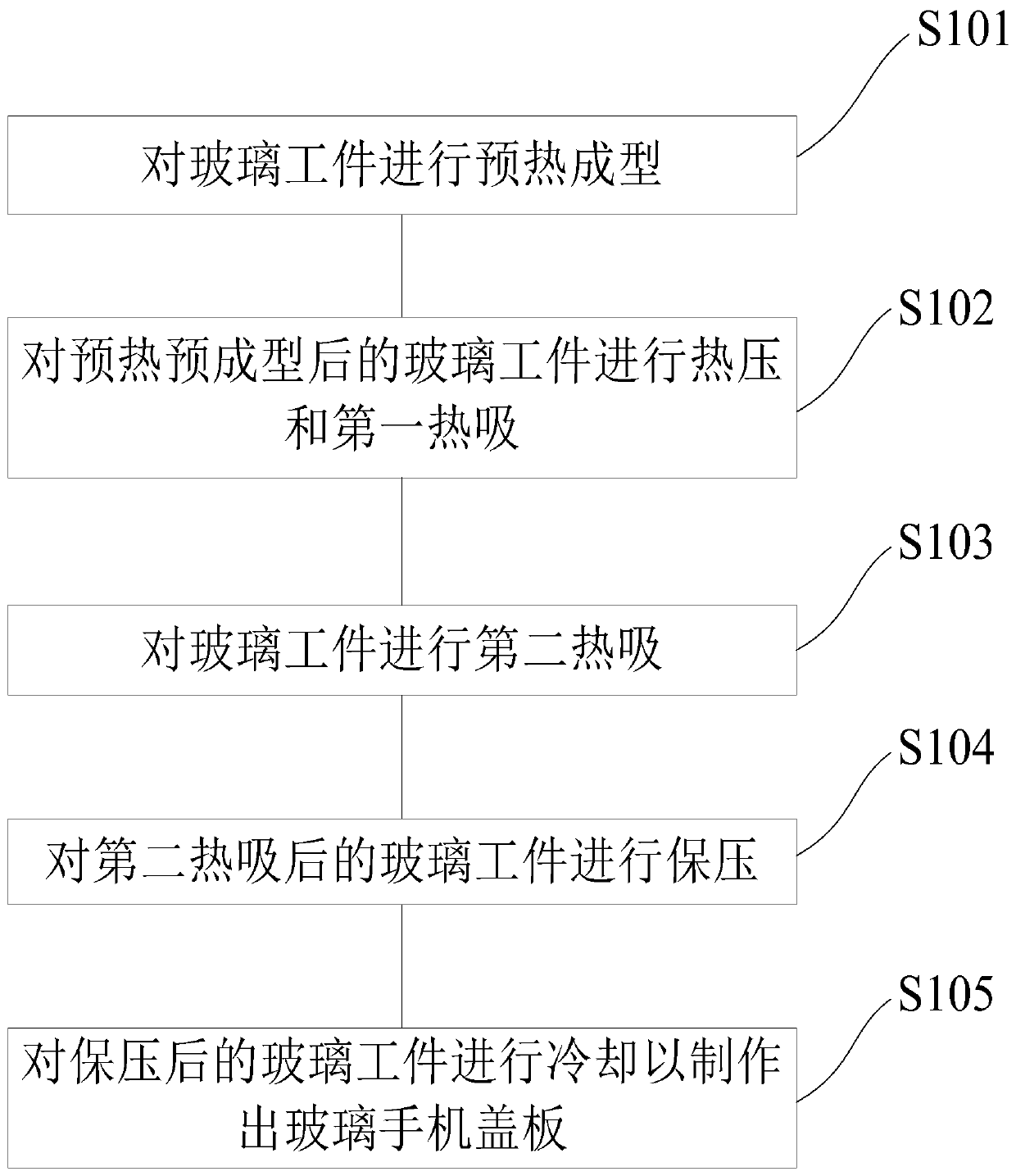

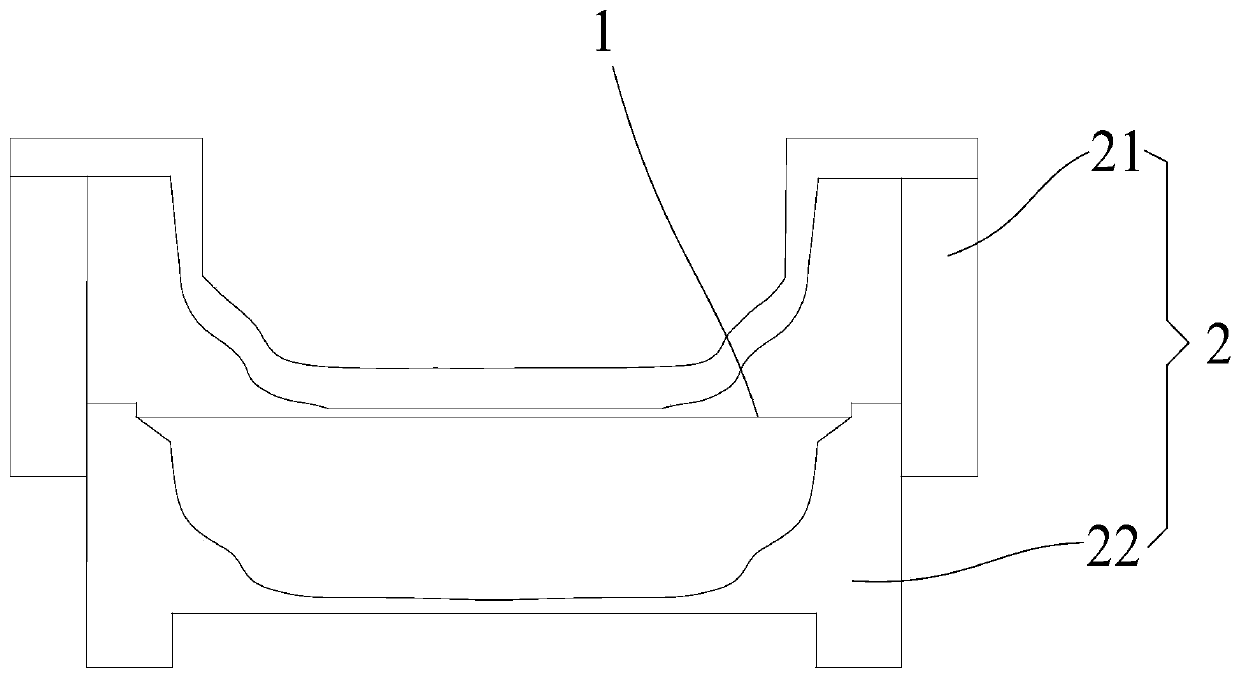

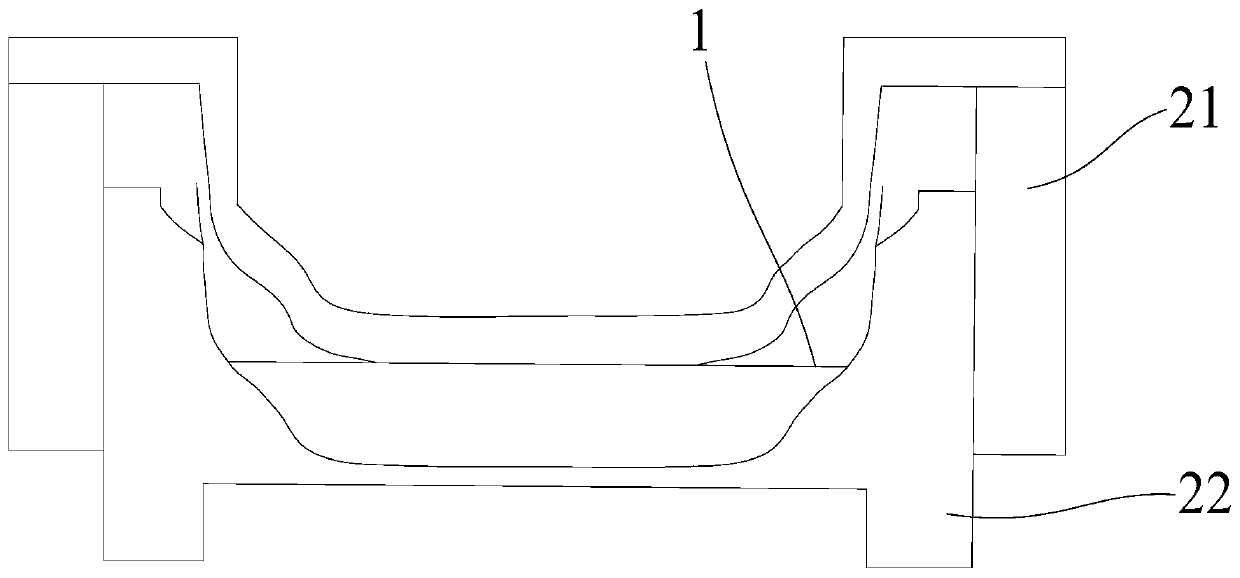

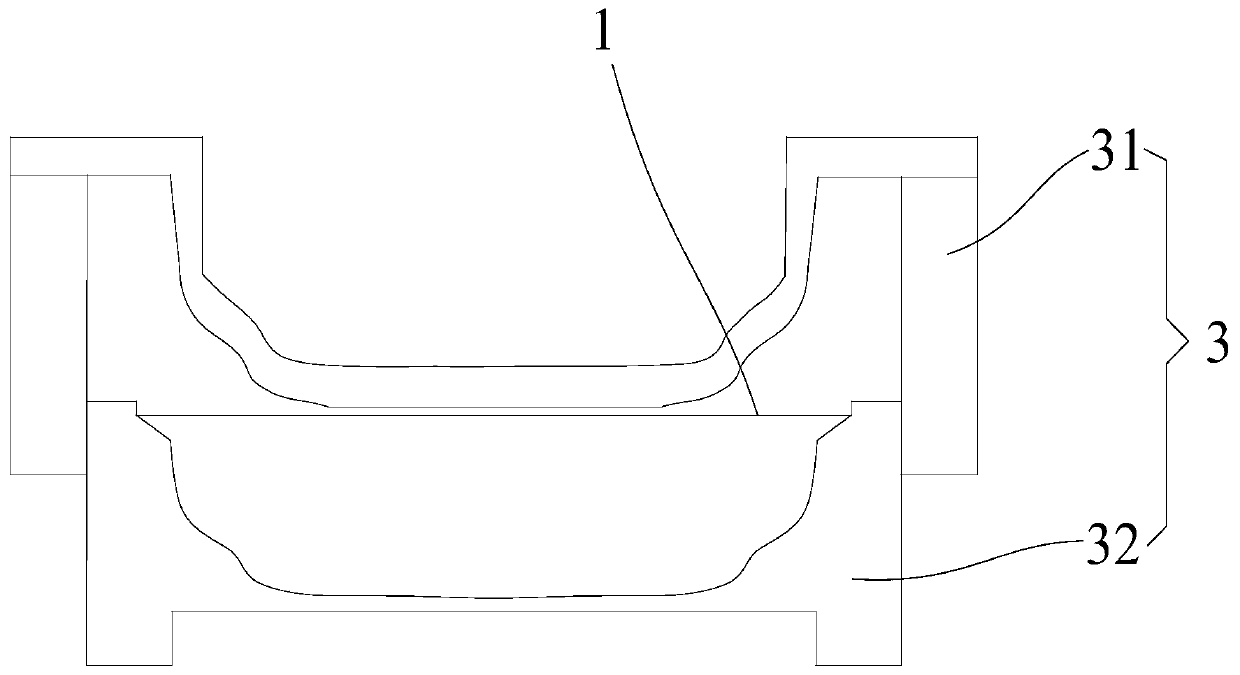

Manufacturing method of hot-bent mobile phone glass cover plate

ActiveCN110040945AGood contourReduce stampingGlass reforming apparatusGlass productionGlass coverEngineering

The invention provides a manufacturing method of a hot-bent mobile phone glass cover plate. The manufacturing method comprises steps as follows: a glass workpiece is subjected to preheated forming, and the glass workpiece after preheated preforming is subjected to hot pressing and first heat absorption; the glass workpiece is subjected to second heat absorption; the glass workpiece after the second heat absorption is subjected to pressure maintaining; the glass workpiece after pressure maintaining is cooled, and the mobile phone glass cover plate is manufactured. The heat absorption process isadded during hot bending of the glass workpiece, hot pressing and first heat absorption are performed simultaneously when the mobile phone glass cover plate is almost formed, then, second heat absorption is performed, the glass workpiece is completely adsorbed on a cavity surface of a die, so that the form of the formed mobile phone glass cover plate can be consistent with drawing, the surface profile is better, tooling marks on the formed mobile phone glass cover plate are reduced, time for the following forming procedure is saved, and the forming efficiency is improved.

Owner:深圳市东方碳素实业有限公司

Guide ejecting pressing type plate cutting device

InactiveCN106217429AReduce stampingAvoid crackingDirt cleaningMetal working apparatusEngineeringMechanical engineering

The invention discloses a guide ejecting pressing type plate cutting device. The guide ejecting pressing type plate cutting device comprises a main body, and further comprises a feeding guiding mechanism, wherein a cutting cavity is arranged inside the main body in the transmission direction of plates; a downward cutting groove is formed in the bottom of the cutting cavity in the vertical direction; a cutter head assembly for fixing a cutter head is arranged at the top of the main body; the cutter head assembly can move in the vertical direction to extend the cutter head into the cutting cavity; lug blocks extend outwards at the bottoms of the two ends of the cutter head assembly in the horizontal direction; vertically extended through holes are formed in the lug blocks; guide rods are arranged in the through holes; pressing blocks are arranged at the bottoms of the guide rods; compression springs are arranged between the pressing blocks and the lug blocks; the feeding guiding mechanism is in front of the main body in the transmission direction of the plates; the feeding guiding mechanism can apply clamping force to the plates in the horizontal direction; the feeding guiding mechanism comprises a base and two L-shaped clamping plates; the two L-shaped clamping plates are arranged at the top of the base to clamp the plates; sliding chutes are formed in the inner sides of the L-shaped clamping plates; and ejecting pressing blocks are arranged in the sliding chutes. According to the cutting device, the plates can be cut excellently.

Owner:芜湖昊轩环保新材料有限公司

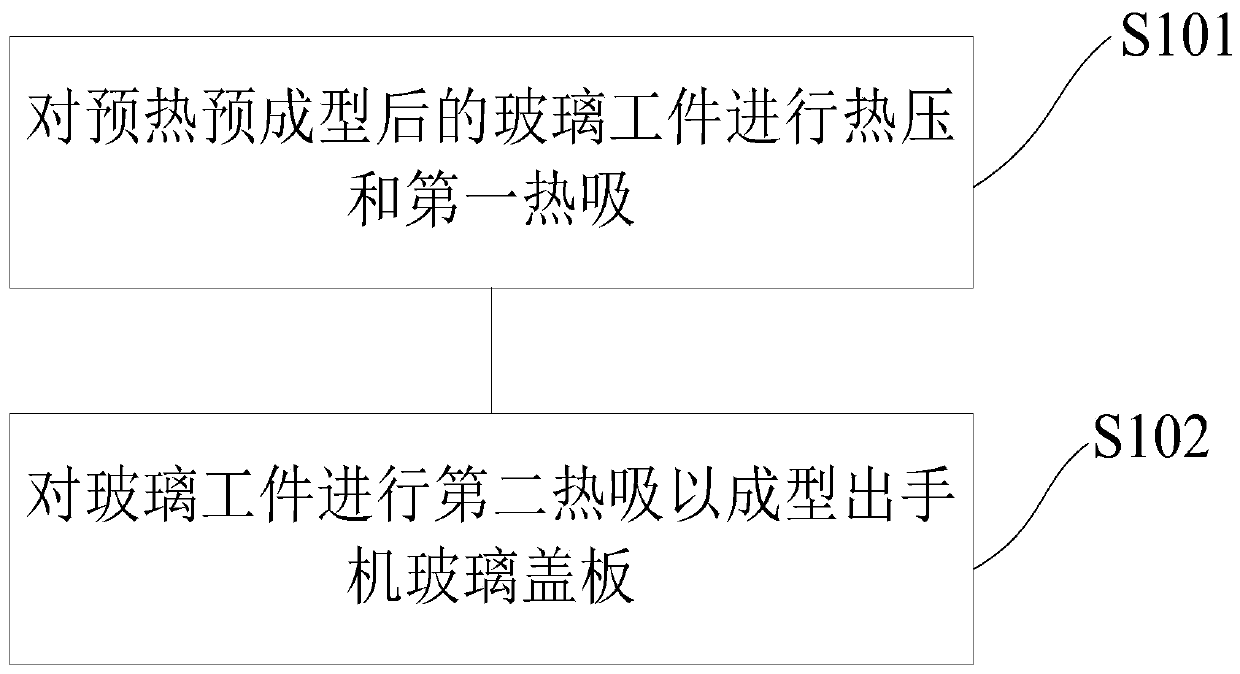

Forming process of hot-bent mobile phone glass cover plate

ActiveCN110040946AGood contourReduce stampingGlass reforming apparatusGlass productionGlass coverEngineering

The invention provides a forming process of a hot-bent mobile phone glass cover plate. The forming process comprises steps as follows: a glass workpiece after preheated preforming is subjected to hotpressing and first heat absorption; the glass workpiece is subjected to second heat absorption, and the mobile phone glass cover plate is formed. The heat absorption process is added during hot bending of the glass workpiece, hot pressing and first heat absorption are performed simultaneously when the mobile phone glass cover plate is almost formed, then, second heat absorption is performed, the glass workpiece is completely adsorbed on a cavity surface of a die, so that the form of the formed mobile phone glass cover plate can be consistent with drawing, the surface profile is better, toolingmarks on the formed mobile phone glass cover plate are reduced, time for the following forming procedure is saved, and the forming efficiency is improved.

Owner:深圳市东方碳素实业有限公司

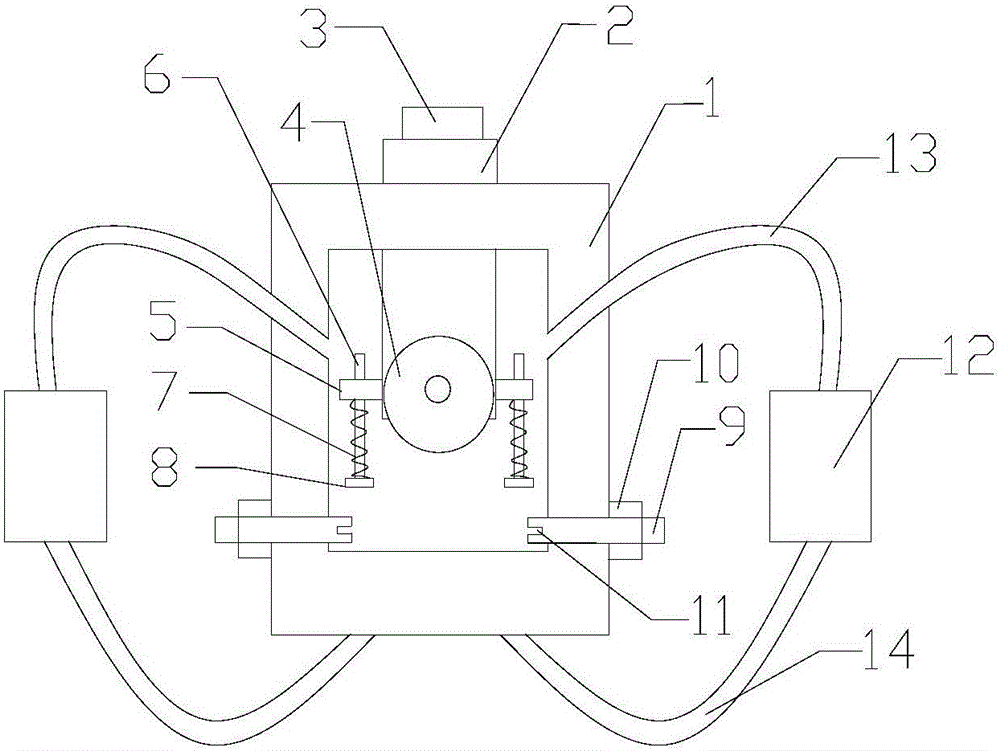

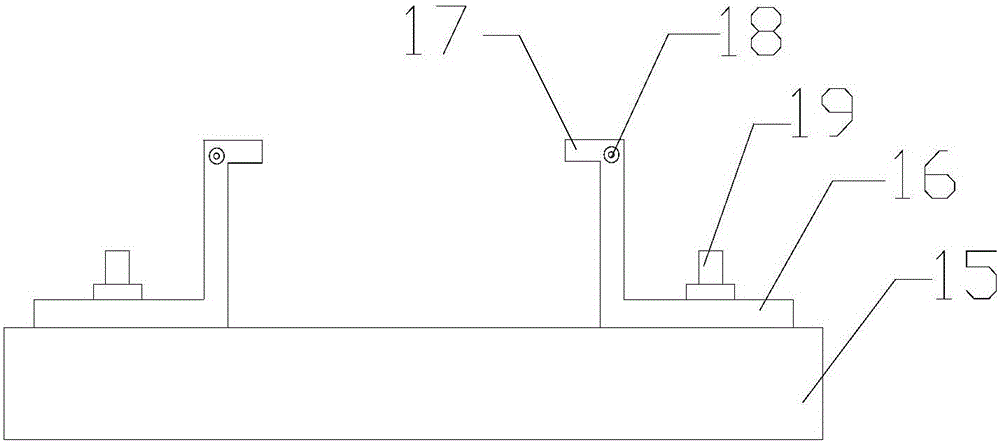

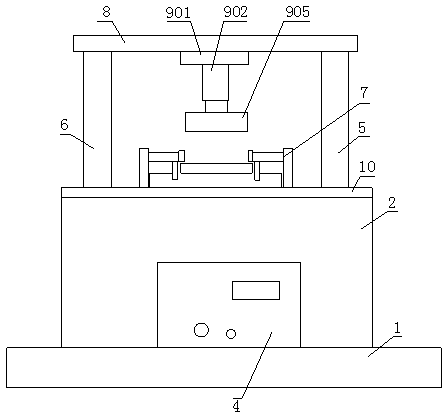

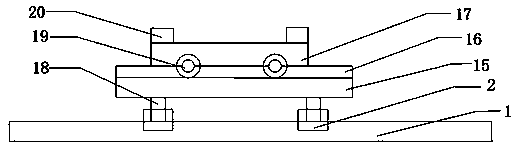

Mold punching and fixing device

InactiveCN111229901AThe overall structure is stableImprove stabilityMetal-working feeding devicesPress ramElectric machineryProcess engineering

The invention discloses a mold punching and fixing device which comprises a base, a machine body, a motor, a control system, a first supporting column, a second supporting column, a fixing device, a supporting transverse column, a punching device and a workbench face. The upper portion of the base is connected with the machine body. The upper portion of the machine body is connected with the workbench face. The upper portion of the workbench face is connected with the first supporting column and the second supporting column. According to the mold punching and fixing device, the overall structure is more stable, the stabilization degree during work is increased, work precision is improved, pressure is increased, molds are punched more rapidly with less labor, production cost is reduced, thework efficiency is increased, the device can adapt to punching of various molds, overall practicality is increased, and the clamping effect is good; and fault operation brought by mold material deviation is avoided, punching is achieved better, unnecessary punching is reduced, friction between molds is reduced, and the service life is prolonged.

Owner:江苏弘汉生物科技有限公司

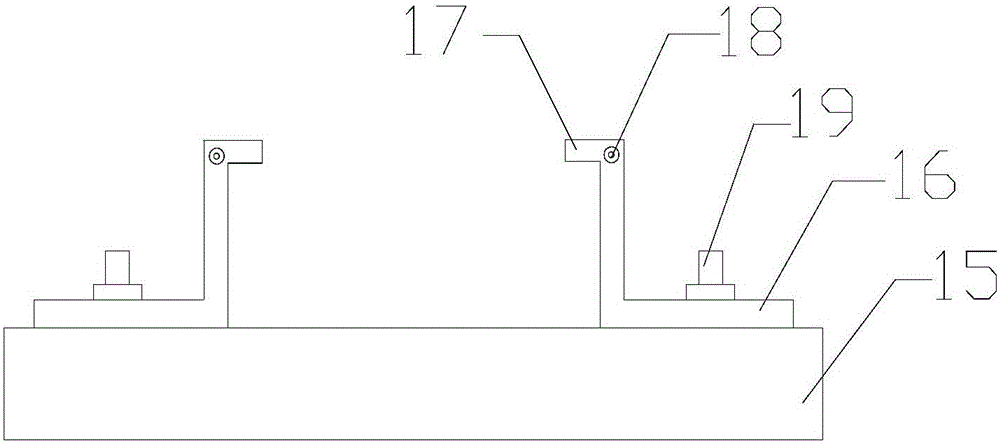

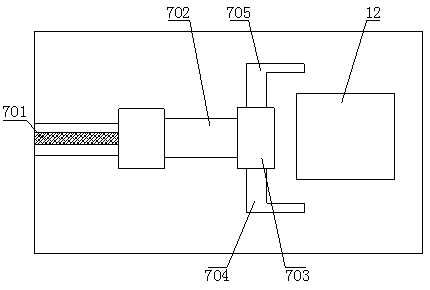

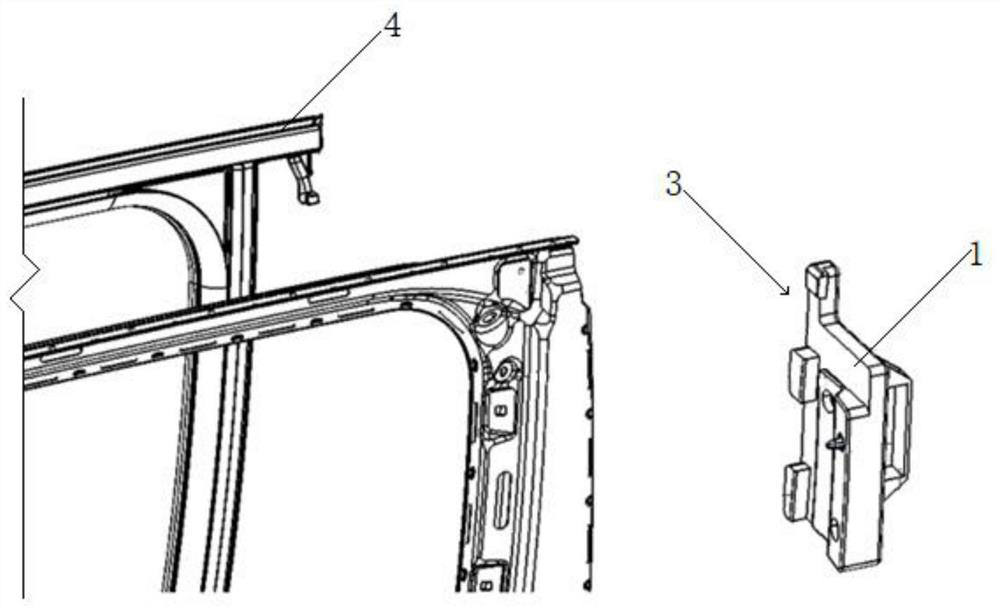

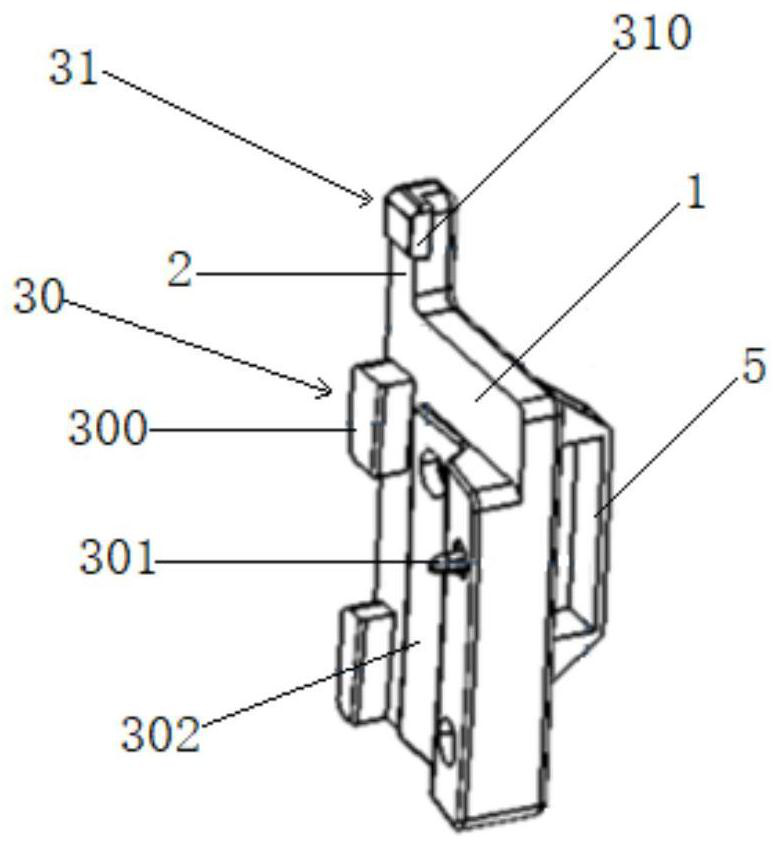

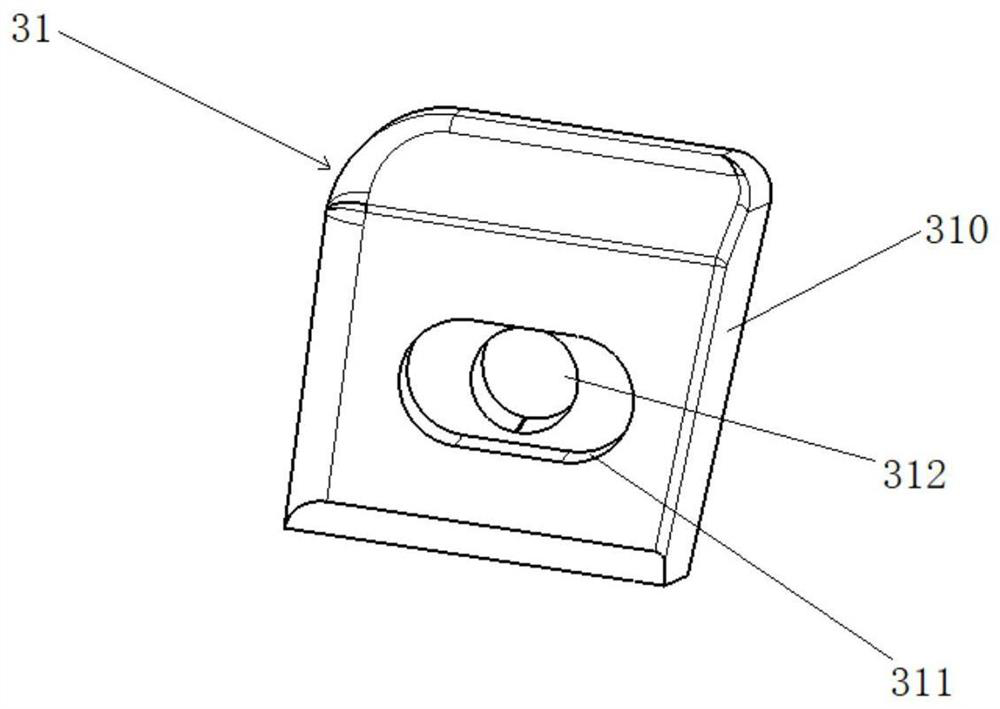

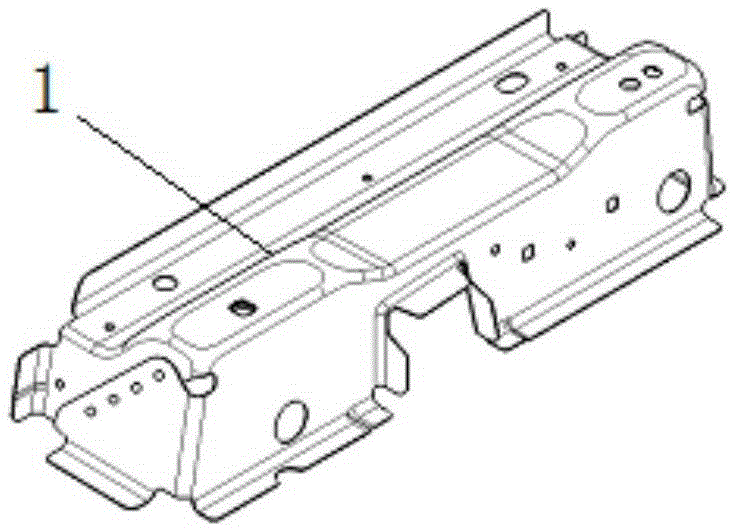

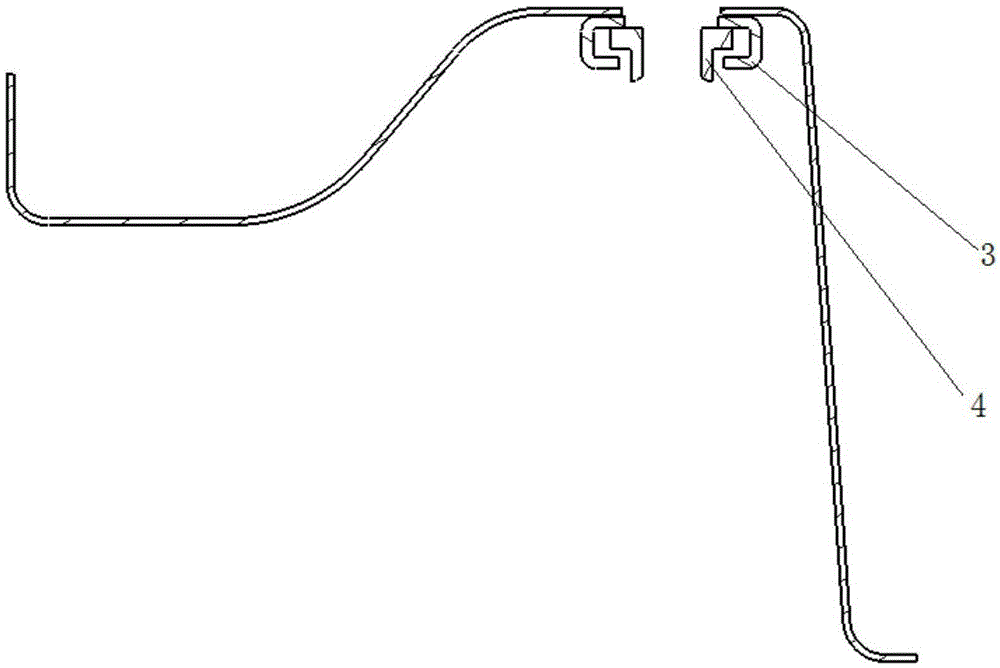

Automobile door glass guide groove auxiliary positioning tool and using method thereof

InactiveCN113400228ALow costLower requirementWork holdersMetal-working hand toolsCar doorManufacturing engineering

The invention relates to an automobile door glass guide groove auxiliary positioning tool and a using method thereof, and relates to the field of automobile windows. The automobile door glass guide groove auxiliary positioning tool comprises a positioning body and a positioning unit, at least part of one end of the positioning body extends forwards to form a fixing part, the positioning unit comprises a first positioning assembly and a second positioning assembly, the first positioning assembly is arranged on one side of the positioning body, the first positioning assembly is provided with a matching surface used for being matched with the corresponding position of an automobile door frame so as to assist the positioning body in positioning the corresponding position of the automobile door frame, and the second positioning assembly is arranged on a fixing part in a relative movement mode and used for limiting a guide groove in the length direction of an automobile door when the first positioning assembly is fixed to the corresponding position of the automobile door frame in a matched mode. According to the automobile door glass guide groove auxiliary positioning tool, the problems that in the prior art, when a guide groove is installed, the overall cost is high, the requirement for the precision of automobile door parts is high, manual alignment is time-consuming and labor-consuming, and the precision cannot be guaranteed are solved.

Owner:VOYAH AUTOMOBILE TECH CO LTD

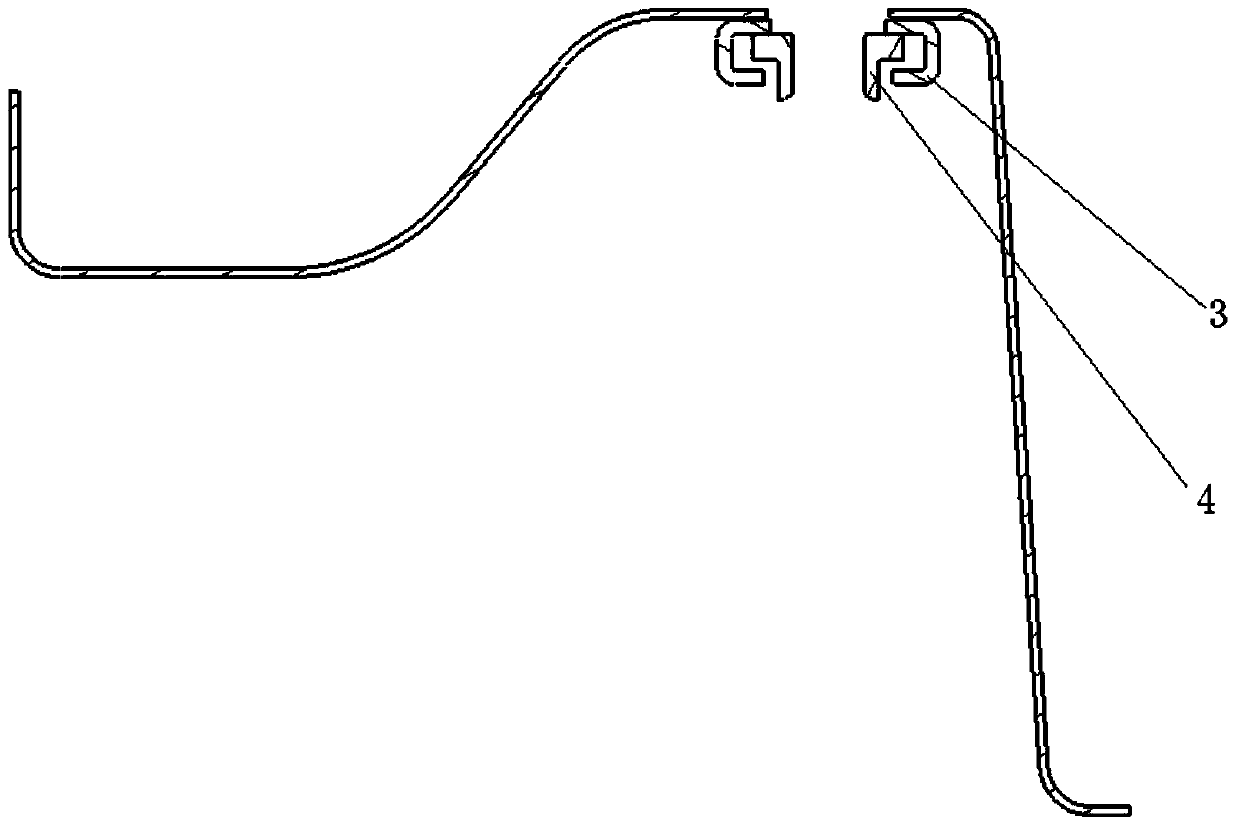

Seat support, production method for seat support, automobile

The invention provides a seat support, a production method for the seat support and an automobile. The seat support comprises a seat bearing plate, a first support structure and a second support structure which are formed in a rolled mode, wherein the first support structure is fixedly arranged at the first end of the seat bearing plate, and the second support structure is fixedly arranged at the second end of the seat bearing plate which is opposite to the first end. The seat support, the production method for the seat support and the automobile can be completed only by a set of rolling mould, and therefore the processes of pressing, bending and the self-welding of the part are saved, and the production cost of the seat support is reduced.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

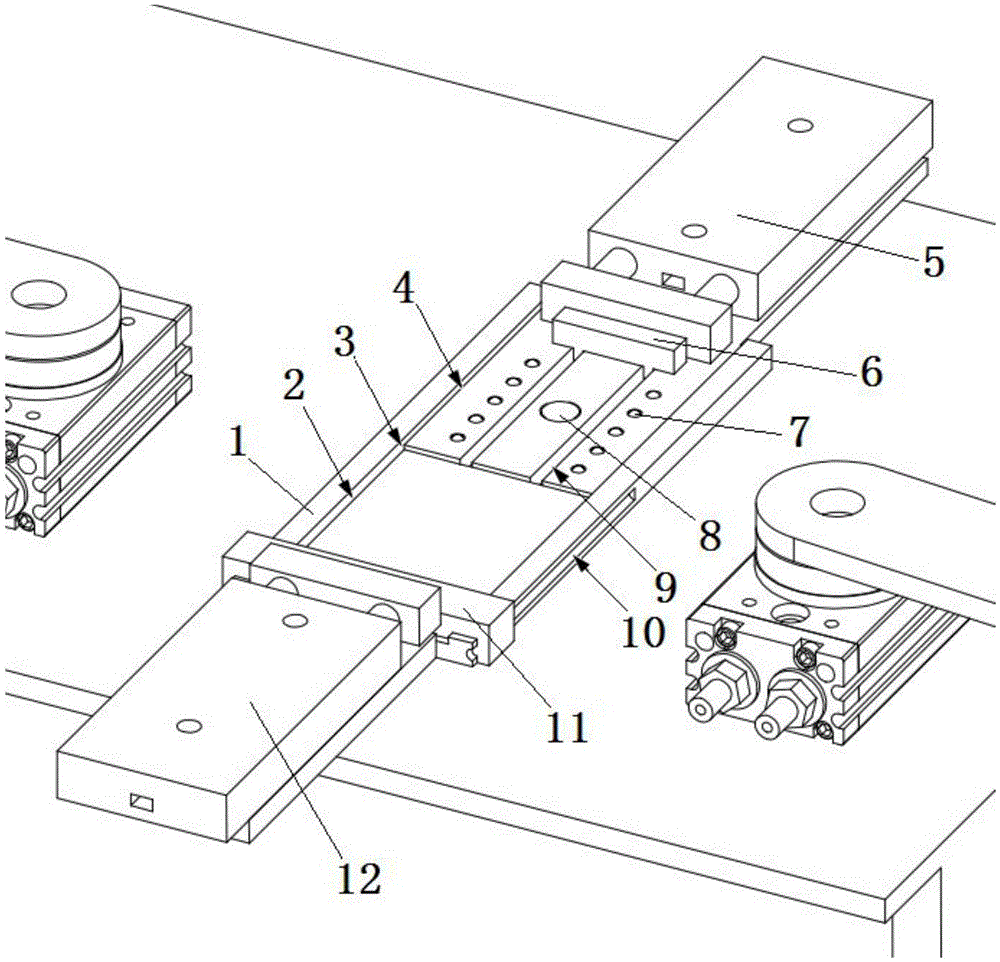

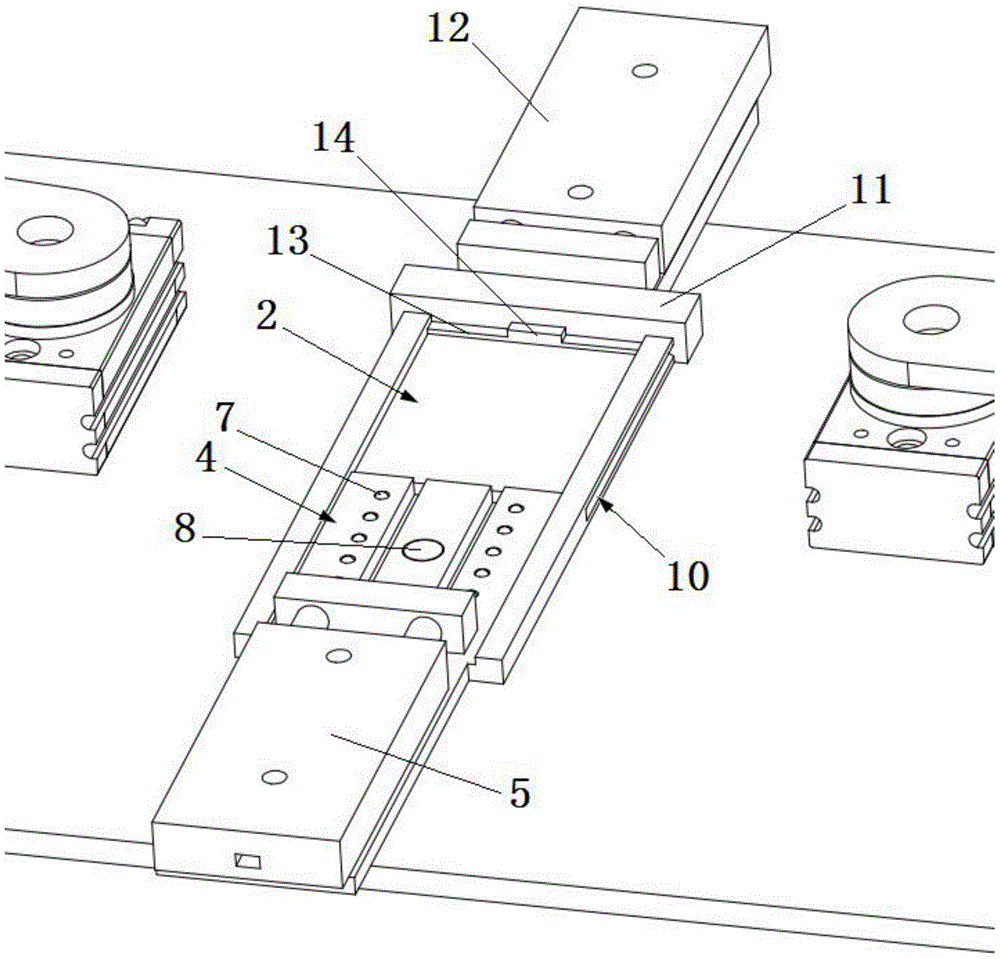

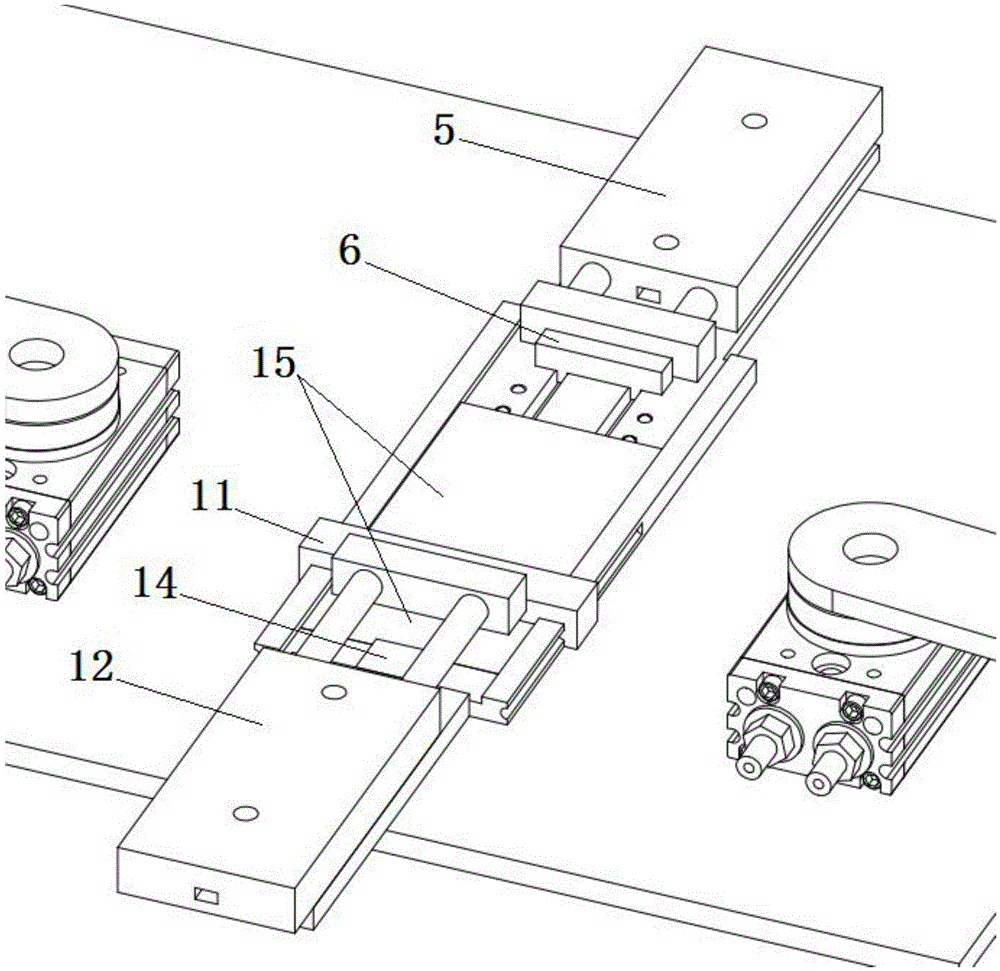

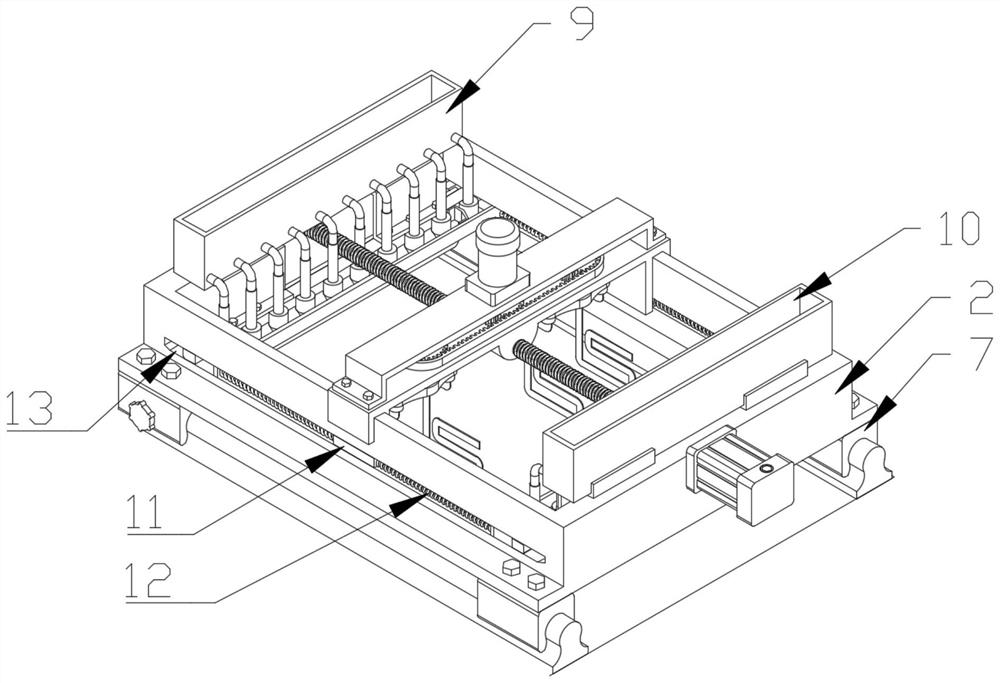

A plate sorting mechanism

InactiveCN104646554BAccurate separationReduce wasteMetal-working feeding devicesPositioning devicesProduction lineRetaining wall

The invention discloses a plate sorting mechanism, and relates to the technical field of part sorting devices. The plate sorting mechanism comprises a bottom plate, wherein the bottom plate is provided with a material containing groove; the inside of the material containing groove is divided into a material separation area and a material waiting area, wherein the material waiting area is higher than the material separation area by a height which is less than or equal to the thickness of one plate; one side, which is opposite to the material waiting area, on the material separation area is provided with a retaining wall; the bottom plate is provided with a sorting pushing block which is used for pushing the plate to the material waiting area from the material separation area; the sorting pushing block is driven by a pushing cylinder; a nearest distance between the part, which slides on the upper side of the material separation area, of the sorting pushing block and the upper surface of the material separation area is greater than or equal to the thickness of one plate and is less than the thickness of two plates; the material waiting area is provided with a returning pushing block which pushes the plate back to the material separation area from the material waiting area; the returning pushing block is driven by a returning cylinder. According to the plate sorting mechanism, in order to solve the problem that a single piece of plate on an automatic production line is difficult to take at present, the invention provides the plate sorting mechanism which has the advantages of high automation degree and can separate and take the single piece of plate.

Owner:李圣阳

Automatic mixing and sizing device for artificial boards

InactiveCN114559520AEasy stampingReduce usageWood working apparatusFlat articlesResin adhesiveMechanical engineering

The invention discloses an automatic mixing and gluing device for artificial boards, which comprises a rack body, and two mutually parallel slide rails are fixedly mounted at the top of the rack body; the sliding rail is connected with a sliding seat in a sliding manner; a sliding type mixing assembly is arranged at the top of the sliding seat; when the device is used, a plate stamping die is filled with raw materials, resin adhesive is poured into the stamping die, then the stamping die is placed in an open groove, and then the sliding type mixing assembly is moved to the position over the open groove and is locked and fixed through a plum blossom handle bolt; at the moment, an electric push cylinder pushes a lifting plate to move upwards along a sliding column, a stamping die tightly abuts against the bottom of a sliding type mixing assembly, then raw materials and resin adhesive in the stamping die are mixed through the sliding type mixing assembly, the use of a stirring tank is omitted, after mixing is completed, the stamping die can be directly taken out for stamping forming operation, and the production efficiency is improved. And the processing efficiency of the artificial board is greatly improved.

Owner:曾光

Central running-gate mould cavity of extruding mould

A central sprue cavity of pressig die is composed of raw material staying tray, sprue cup, and internal sprue consisting of upper segment whose cross-section is gradually decreased and lower segment whose cross-section is gradually increased. Its advantages are low pressure to die and die locking force, and easy breaking off of prue on demoulding.

Owner:象山昌盛汽车空调模具厂

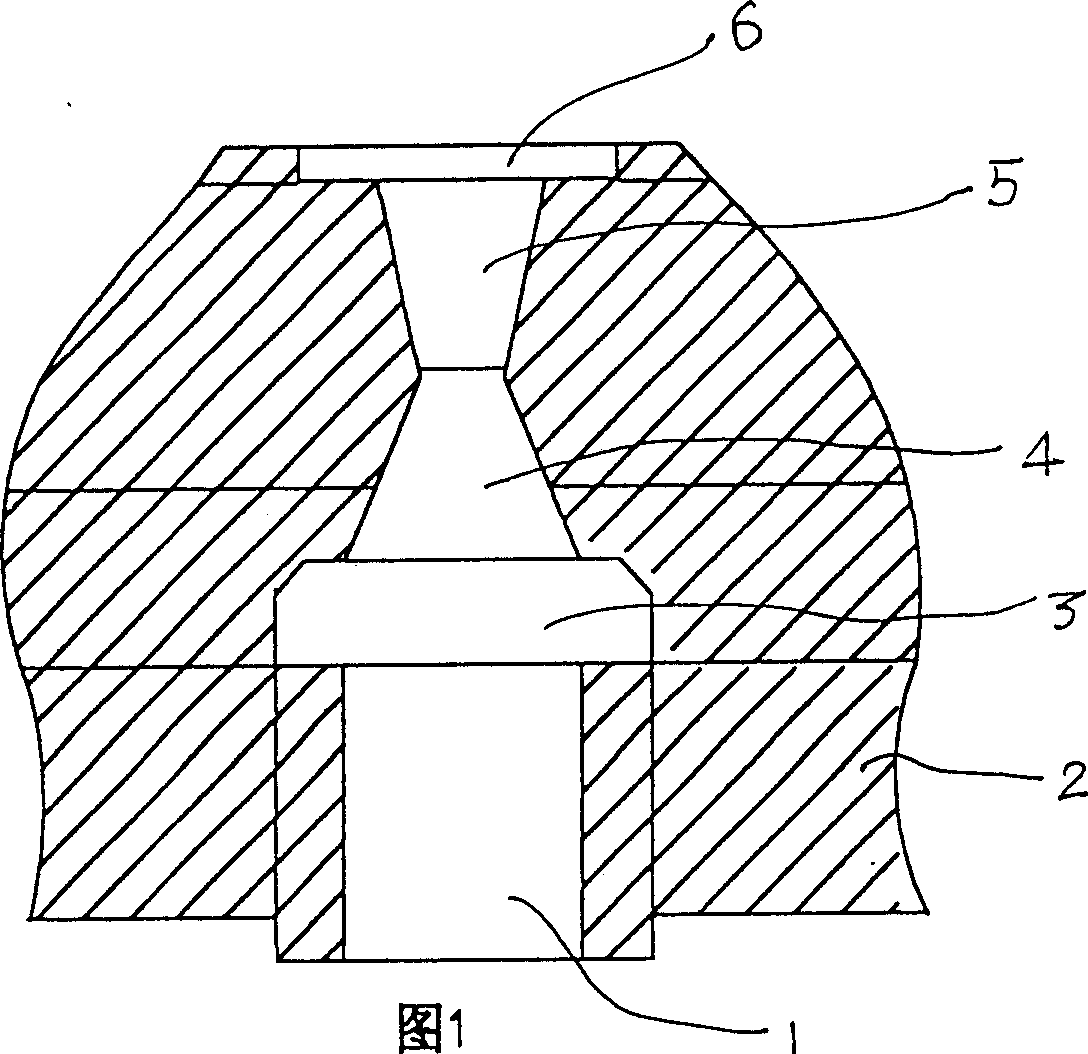

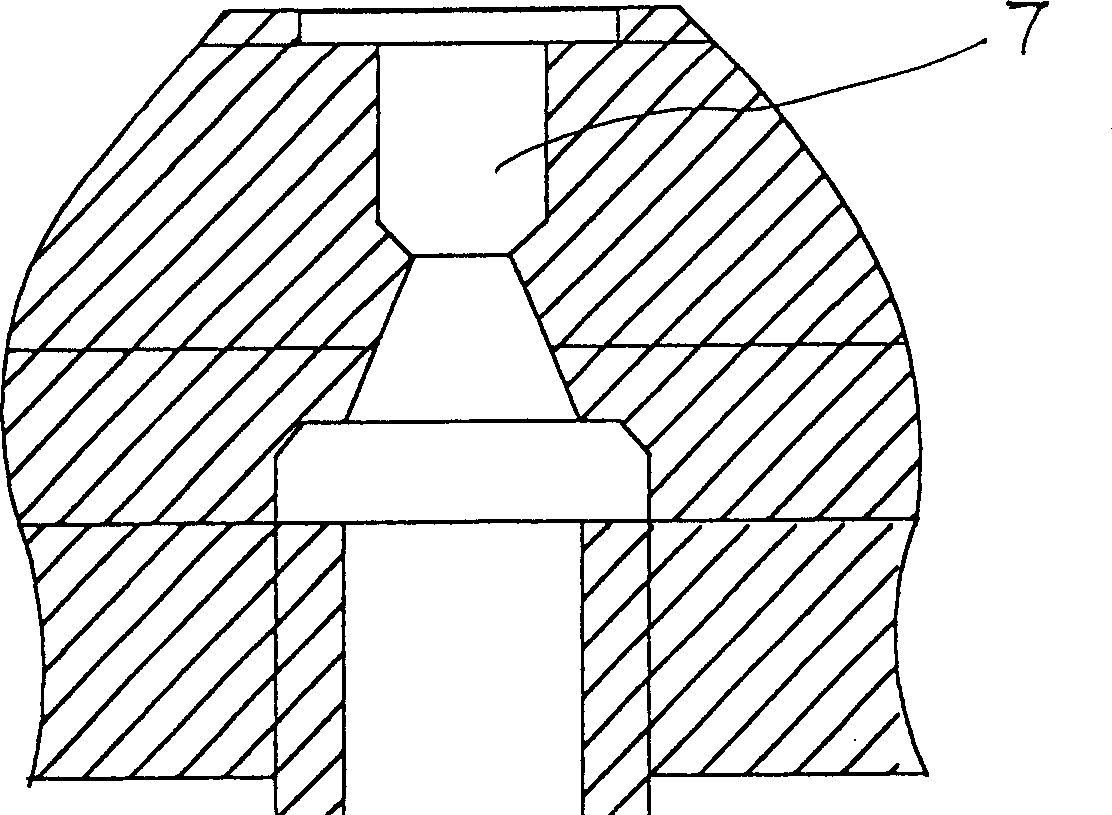

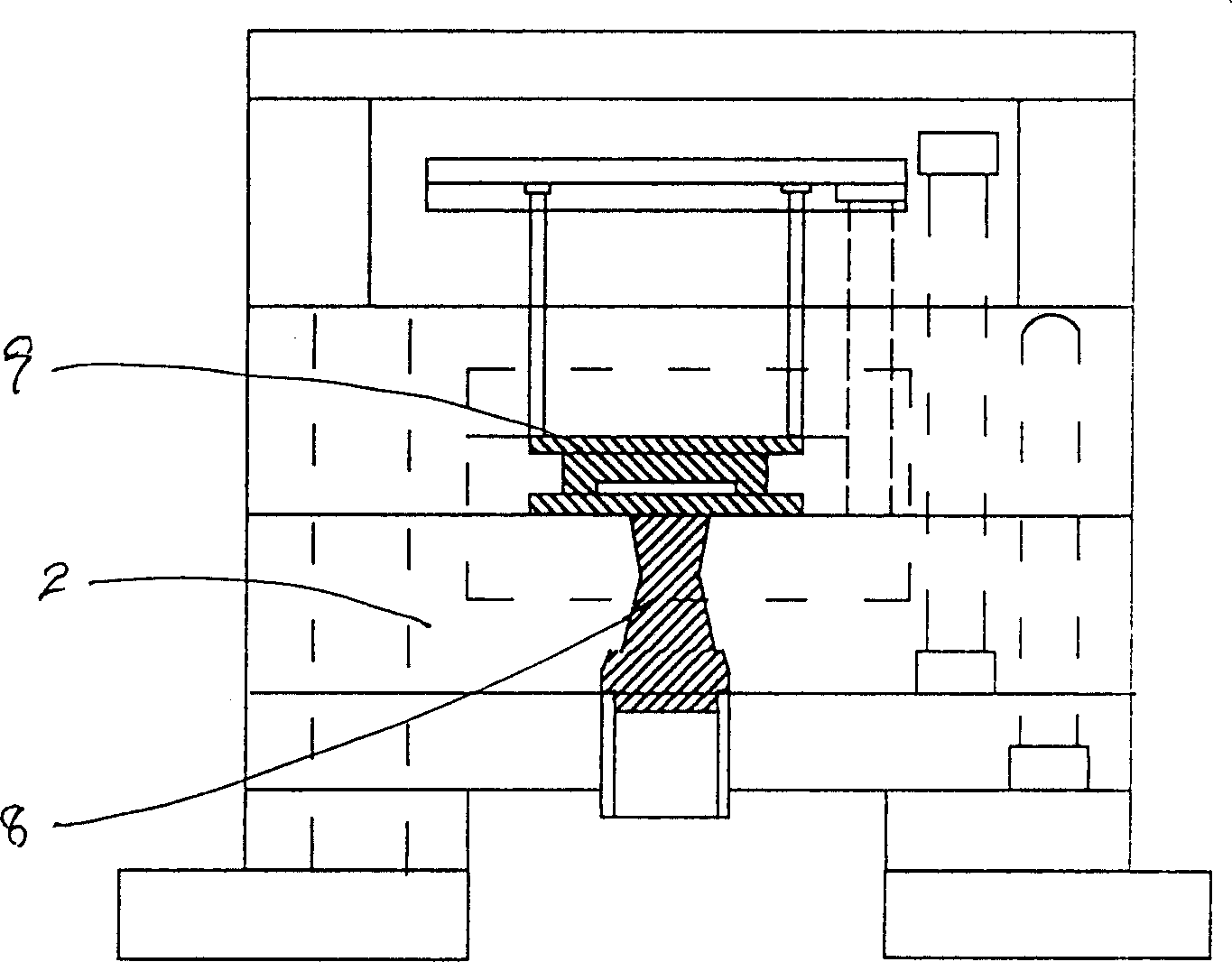

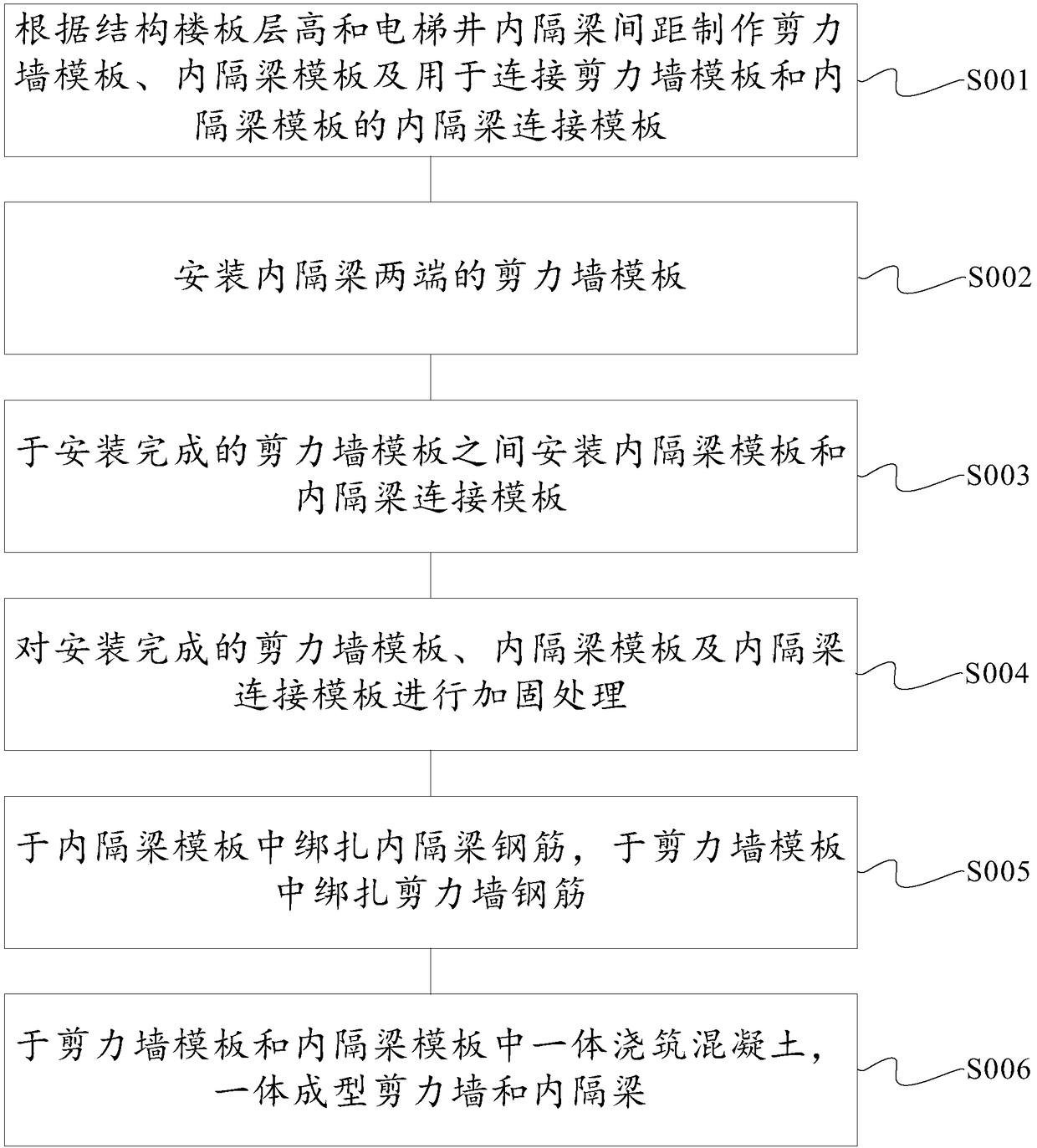

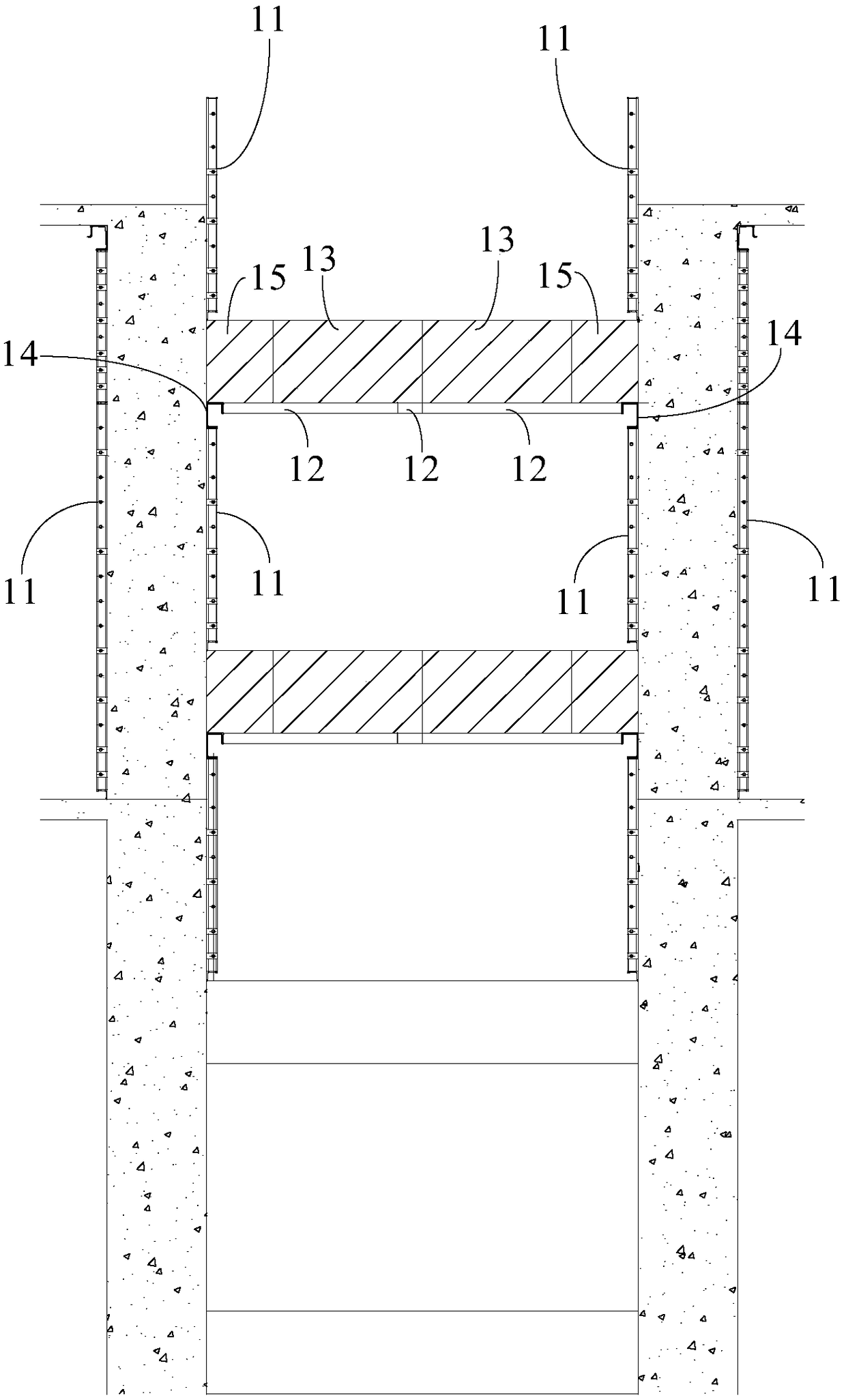

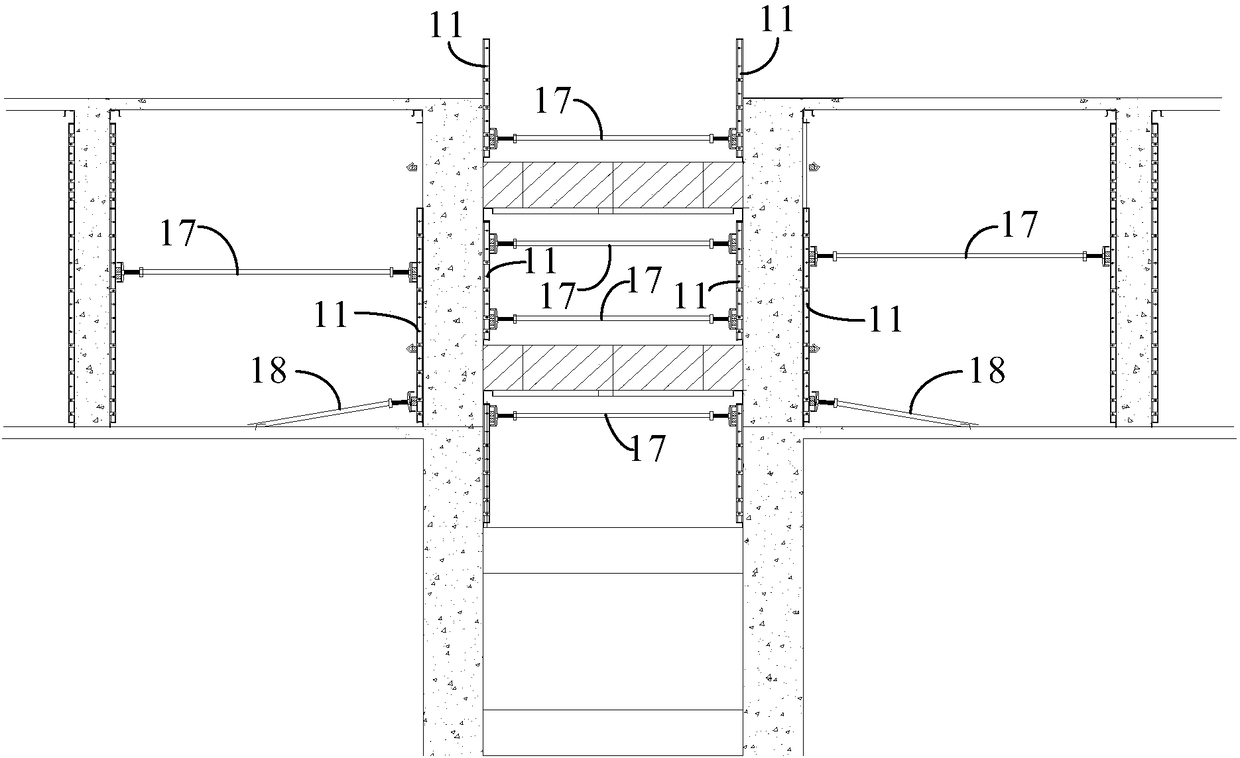

One-time pouring forming construction method of partition beam in elevator shaft

ActiveCN106677527BEasy constructionImprove construction progressForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFloor slabRebar

The invention discloses a construction method for pouring forming of inner partition beams in an elevator well. The construction method comprises the steps that according to a structural floor layer height and the spacing among the inner partition beams in the elevator well, shear wall formworks, inner partition beam formworks and inner partition beam connecting formworks are made, wherein the inner partition beam connecting formworks are used for connecting the shear wall formworks and the inner partition beam formworks; the shear wall formworks at the two ends of the inner partition beams are mounted; the inner partition beam formworks and the inner partition beam connecting formworks are mounted between the shear wall formworks which are completely mounted; strengthening treatment is conducted on the shear wall formworks, the inner partition beam formworks and the inner partition beam connecting formworks which are completely mounted; Inner partition beam steel bars are bound in the inner partition beam formworks, and shear wall steel bars are bound in the shear wall formworks; and integral concrete pouring is conducted in the shear wall formworks and the inner partition beam formworks, and shear walls and inner partition beams are integrally formed. A whole formwork system is composed of inner partition beam bottom moulds, inner partition beam side moulds and the shear wall formworks, wherein the shear wall formworks are in the area where the inner partition beams are located, so that one-time pouring construction of the elevator well in the shear walls and the structural beam plates is realized, the construction of the inner partition beams is simplified, and the construction process is accelerated.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

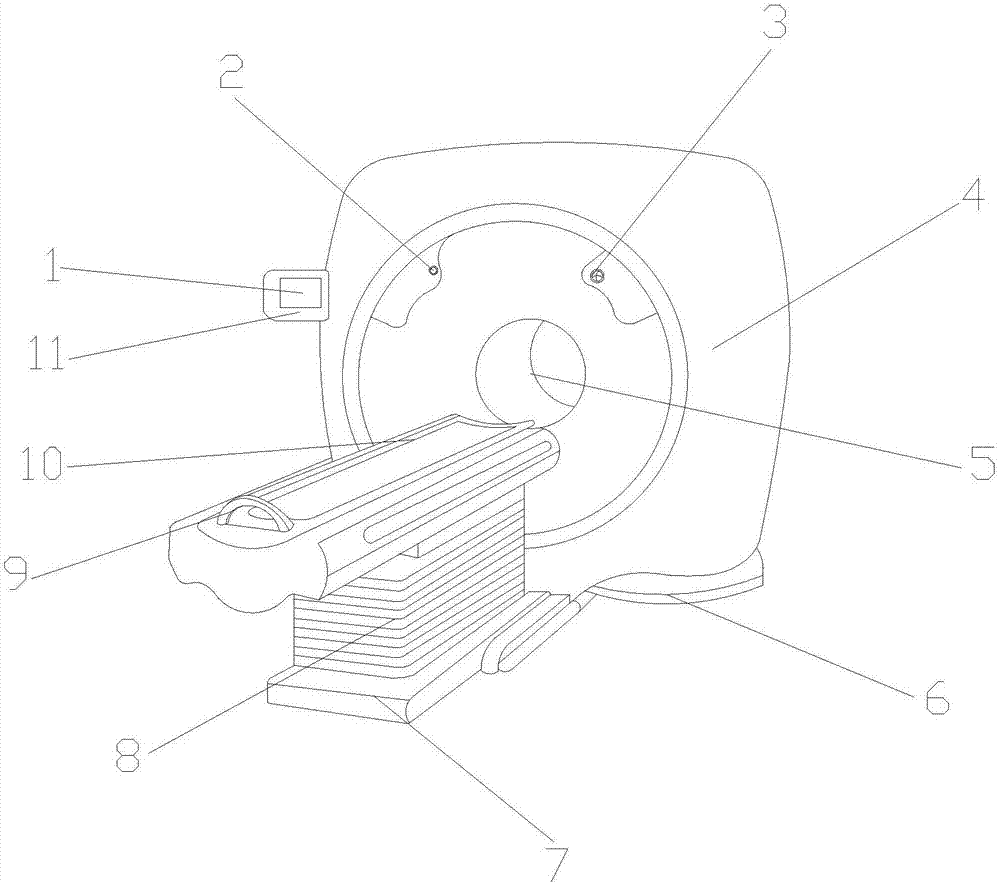

Tumor diagnosis device for gynecology department

InactiveCN107961011APlay a role in heat preservationGood flexibilityDiagnostic recording/measuringSensorsDamping functionDisplay device

The invention discloses a tumor diagnosis device for the gynecology department. The structure of the tumor diagnosis device comprises a digital display screen, an indicator lamp, a function button, atumor examination device, an observation hole, a shake-proof base, a support base, compression-resistant rubber, a hand lifting rod, an examination bed and a display, wherein the indicator lamp is connected on the tumor examination device in an embedding manner, the function button is mounted in the tumor examination device in an embedding manner, the top of the support base attaches to the bottomof the compression-resistant rubber, the compression-resistant rubber is connected with the examination bed, the observation hole is formed in the tumor examination device, and the hand lifting rod is welded to the examination bed. For the tumor diagnosis device for the gynecology department, the examination bed is arranged structurally, an insulating layer in the examination bed plays a thermalinsulation role for the examination bed, a rubber layer and a spring layer can improve the flexibility of the examination bed, the pressing caused by a patient to an examination bed position can be reduced, so that the use is comfortable, a damping function can be effectively realized on the examination bed, and a comfortable feeling is brought to people.

Owner:镇江市仑宇广告有限公司

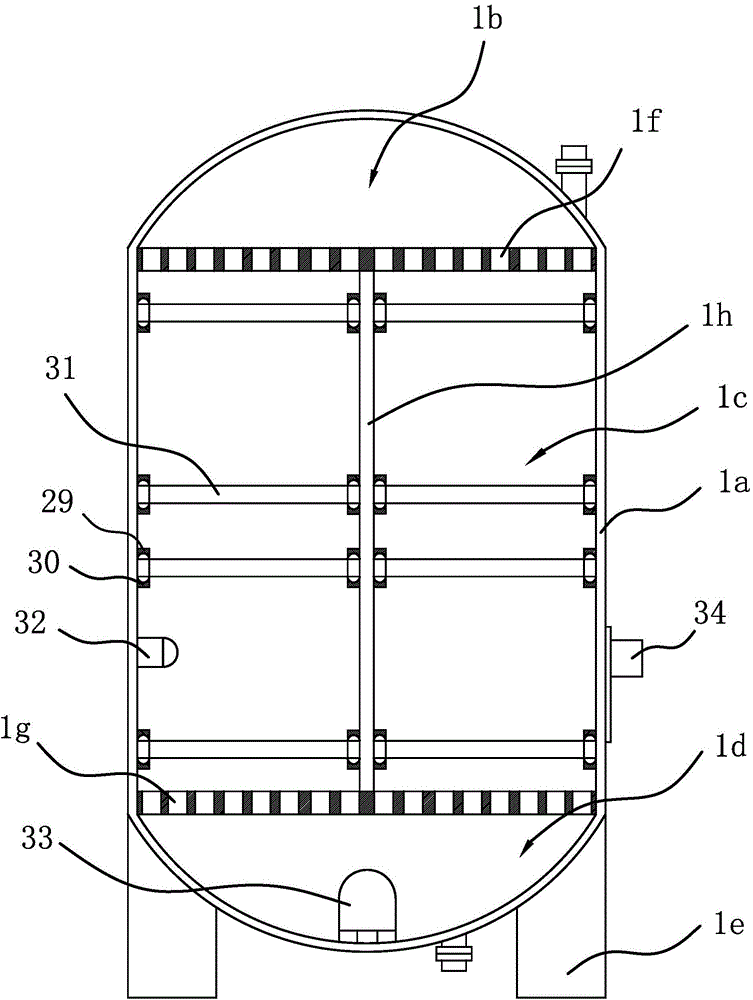

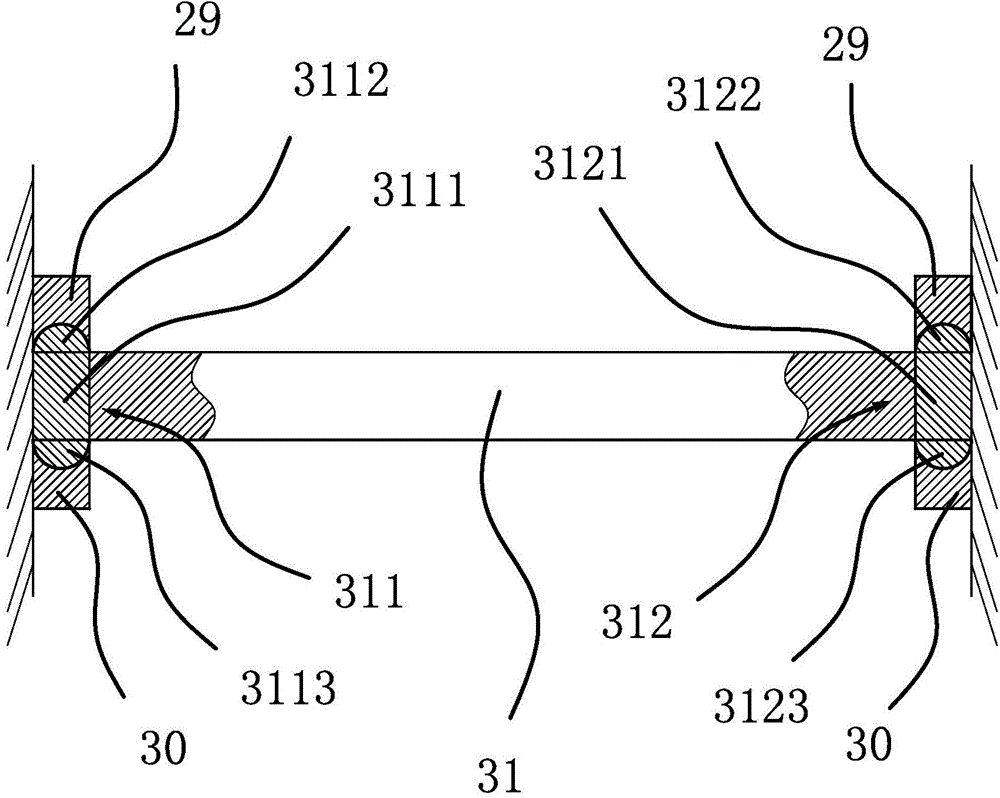

A coal mine underground video monitoring system with automatic charging and mirror cleaning and its application

ActiveCN112738479BStable jobLittle outside influenceTelevision system detailsColor television detailsVideo monitoringDust control

The invention discloses a coal mine underground video monitoring system capable of automatic charging and mirror surface cleaning and its application, including a protection device, a lighting device, a cleaning device, a lifting device, a control device, a blowing device, a grabbing device, and an energy device. The control device realizes the intelligent operation of the video surveillance system. The protection device can make the whole anti-corrosion and explosion-proof. The brush is used to clean the lens to avoid excessive dust influence. The lifting device realizes the up and down movement and 360° rotation of dynamic video monitoring under the action of the control device. The blower in the blower device dedusts the lens through the explosion-proof hose under the action of the control device. Drying, the grabbing device realizes the replacement of rechargeable batteries through the flying manipulator, and the charging base station in the energy device is used to store spare rechargeable batteries to ensure the long-term stable operation of the video surveillance system.

Owner:SHANDONG UNIV OF SCI & TECH

Explosion-proof capacitor

InactiveCN105489373ASimple structureSolve the problem that solder joints are susceptible to temperatureCapacitorsPolypropyleneEngineering

The invention discloses an explosion-proof capacitor, which comprises a shell, an explosion-proof end cover, a positive electrode pin and a negative electrode pin, wherein two vertical core rods and polypropylene film layers are arranged in the shell; each polypropylene film layer is wound outside the corresponding core rod; two mounting holes are symmetrically formed in the explosion-proof end cover; and the positive electrode pin and the negative electrode pin pass through the two mounting holes in the explosion-proof end cover and are connected with a positive electrode wiring and a negative electrode wiring respectively. The explosion-proof capacitor is simple in structure and multi-sealed; the problem that a solder joint is easily affected by the temperature in a traditional welding sealing technology is solved; mounting and stamping of elements are facilitated by a connecting hole with a waist-shaped structure; loss of the capacitor in the operating process is reduced through an arranged insulating sleeve; various electrical properties of the capacitor are improved; the service lifetime of the capacitor is prolonged; and the capacitor can be safe, explosion-proof and safe to use through arranged explosion-proof end cover and explosion-proof plate.

Owner:SUZHOU QUANSU SHIP ELECTRONICS CO LTD

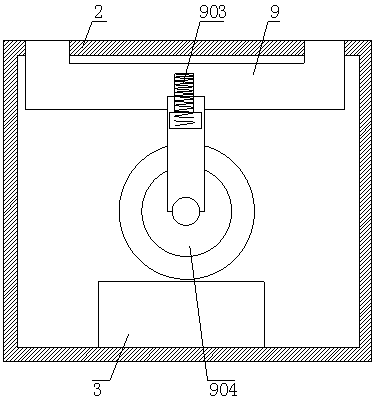

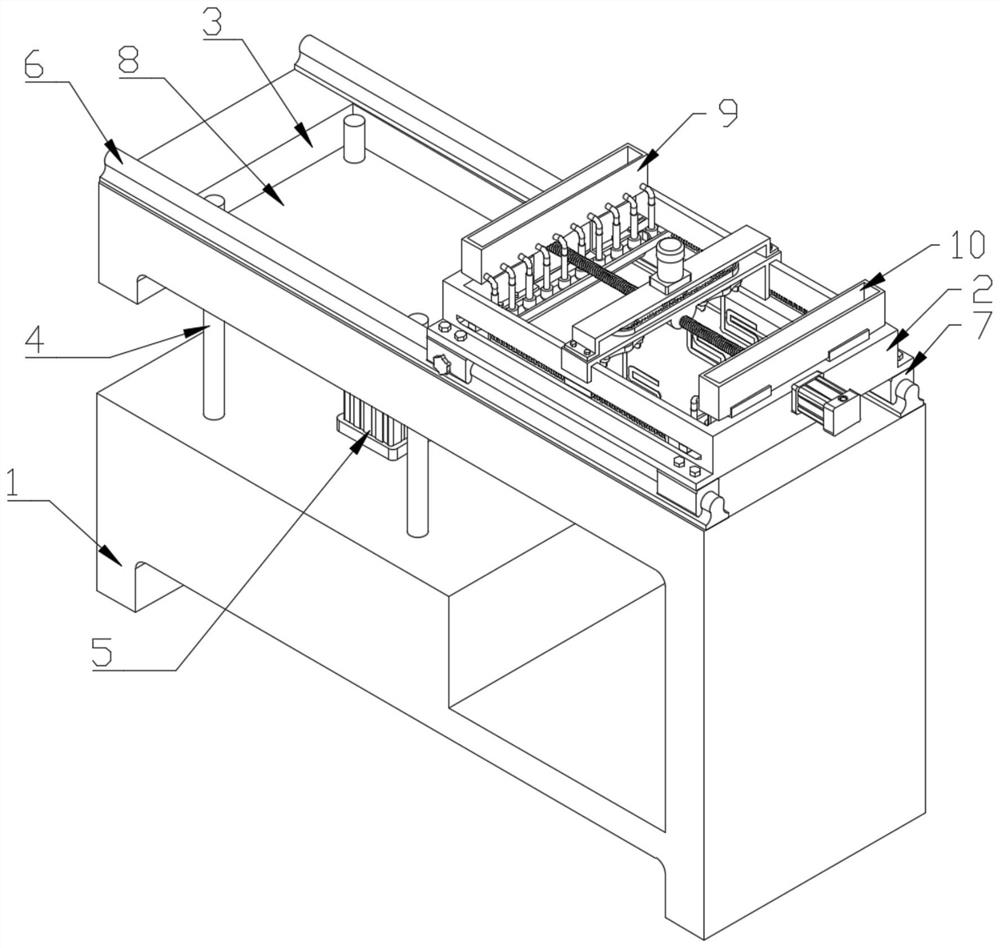

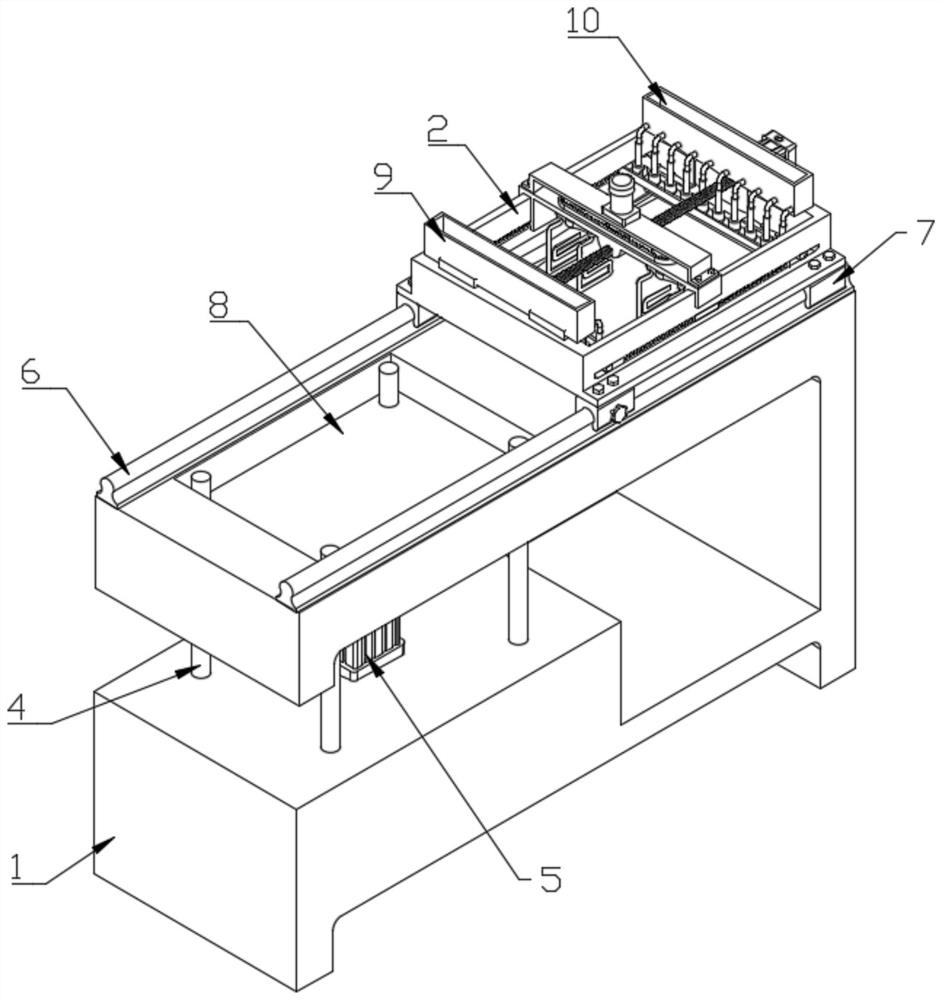

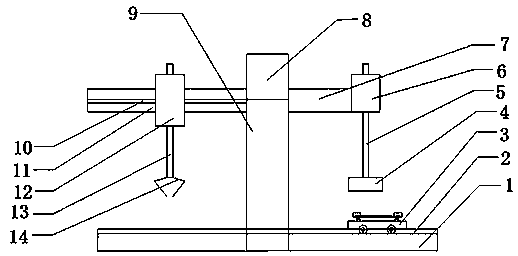

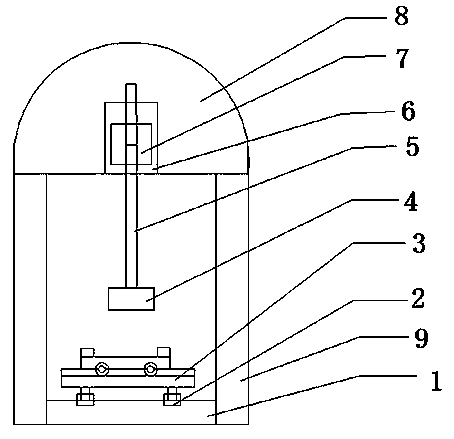

Mechanical equipment used for forging and pressing

InactiveCN108015209AReduce stampingImprove work efficiencyForging/hammering/pressing machinesForging press detailsPunchingEngineering

The invention relates to mechanical equipment used for forging and pressing. The mechanical equipment comprises a base, a support rack, a crossbeam A, crossbeam B, a driving box body, support racks, across beam A, a crossbeam B, a driving box body, a punching machine, a pick-up machine and a movable trolley. Two parallelly-installed first guide rails are installed on the upper surface of the base. The first guide rails are mounted in the right center of the base. The movable trolley is installed on the first guided rails. The support racks are arranged on two sides of the middle of the base and in rivet joint with the base. The tops of the support racks are equipped with the driving box body. The right side of the driving box body is equipped with the crossbeam A. The right end of the crossbeam A is in rivet joint with the punching machine. The left side of the driving box body is provided with the crossbeam B, on which a sliding rail is arranged. The pick-up machine is installed on the sliding rail. The middle of the punching machine is equipped with a sliding circular column A. The bottom of the sliding circular column A is in rivet joint with a punching hammer. The middle of the pick-up machine is equipped with a sliding circular column B. The bottom of the sliding circular column B is equipped with a pick-up clip. By integrating punching and clamping processes, an ordinarypunching process is reduced. The working efficiency is increased.

Owner:成都沃夫铌科技有限公司

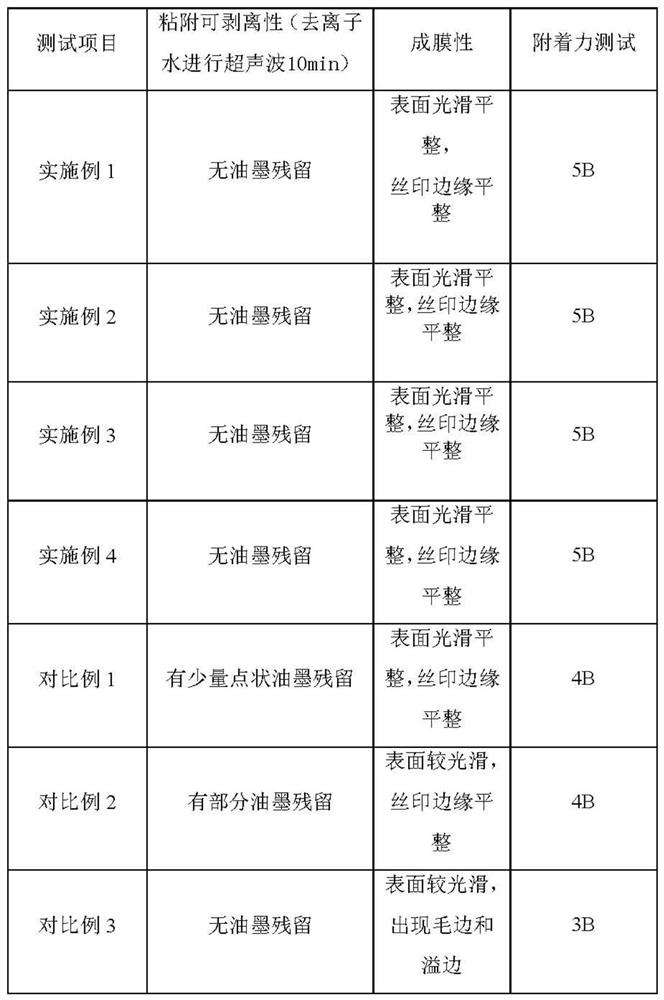

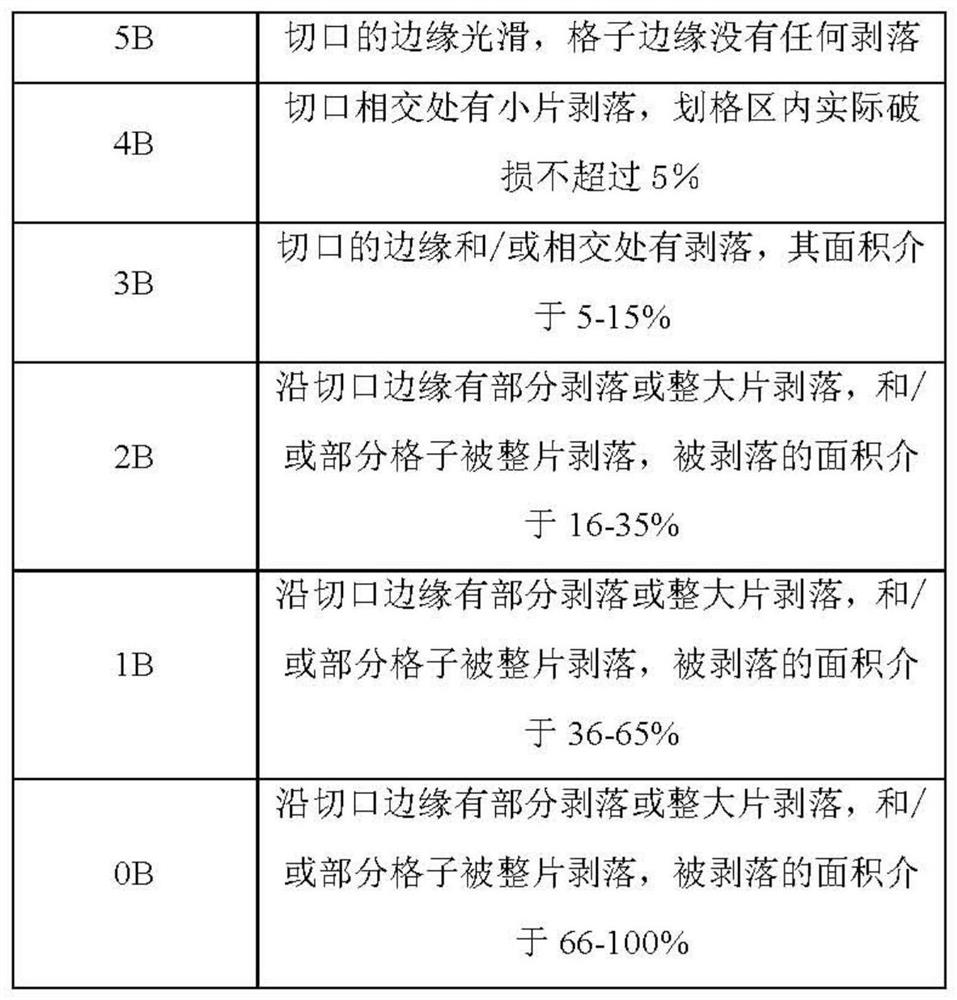

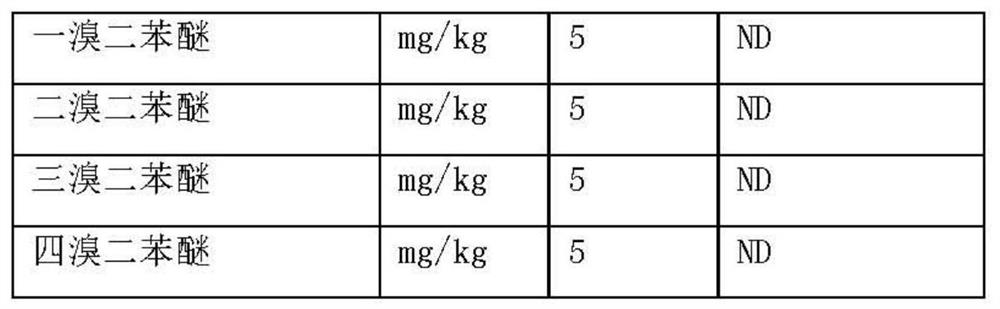

High-temperature-resistant protective ink and preparation method thereof

InactiveCN111690286AImprove performanceGood high and low temperature resistanceInksMolten stateTitanium

The invention relates to the technical field of ink printing, in particular to high-temperature-resistant protective ink and a preparation method and application thereof. The protective ink is prepared from the following raw materials: 36 to 40 parts of a component A, 4 to 6 parts of silicon dioxide, 28 to 32 parts of calcium sulfate crystals, 1.6 to 2.4 parts of rutile titanium, 8 to 12 parts ofPTFE, 11 to 15 parts of talcum powder, 0.7 to 1.2 parts of a leveling agent and 0.7 to 1.3 parts of an antifoaming agent. The prepared protective ink is coated on the surface of glass to be subjectedto hot bending forming, can effectively protect the molten state of the glass in the high-temperature process, can play a role in buffering, reduces mold marks formed by extrusion of a mold on the glass, reduces scratches formed by exposure of the glass, and effectively improves the product processing yield. The protective ink is excellent in high-temperature resistance, can be removed by adoptinga cleaning agent or water, solves the problem that the traditional protective glue is not resistant to high temperature, is easy to peel off, has no residue and no frame, and can improve the productyield and reduce the cost.

Owner:东莞市铂华光电材料有限公司

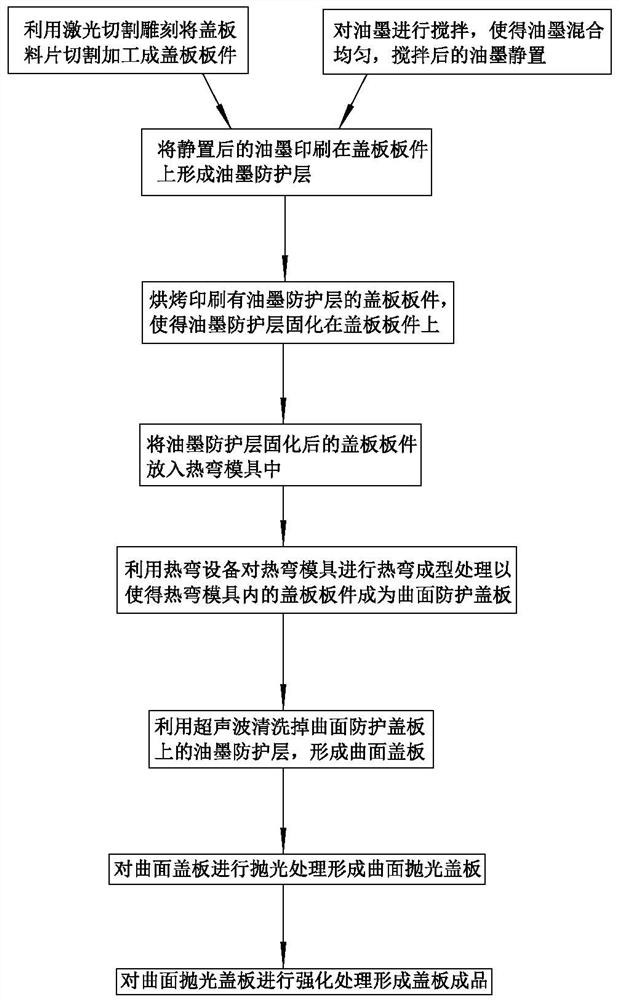

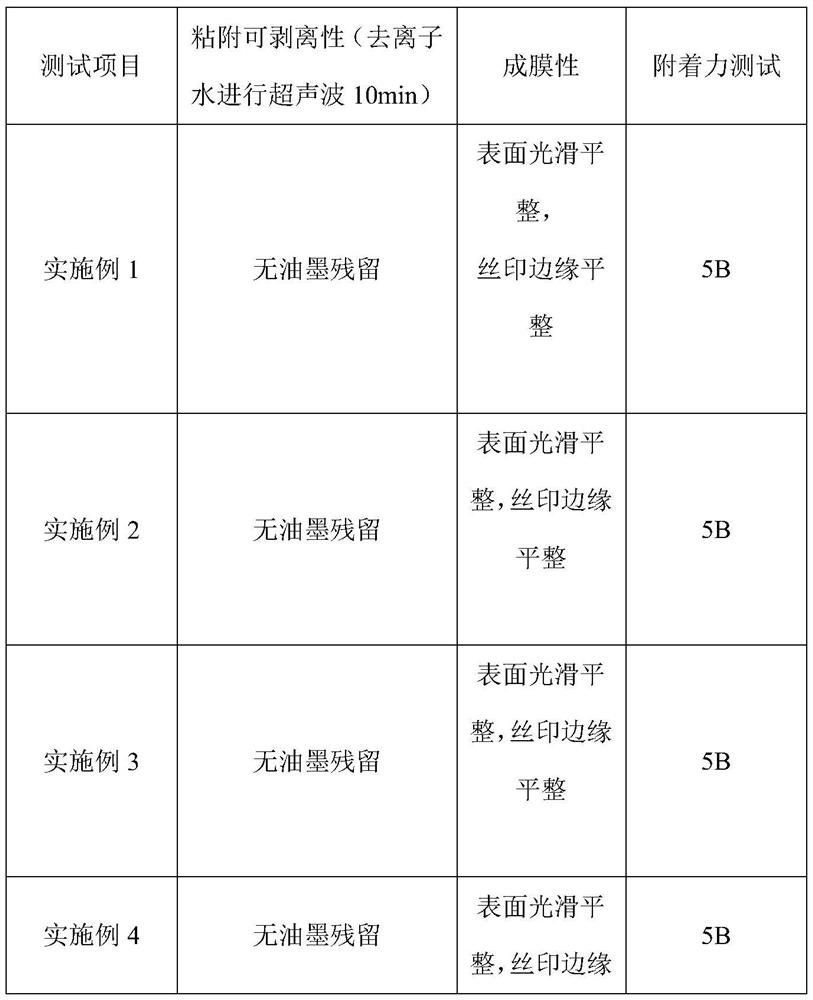

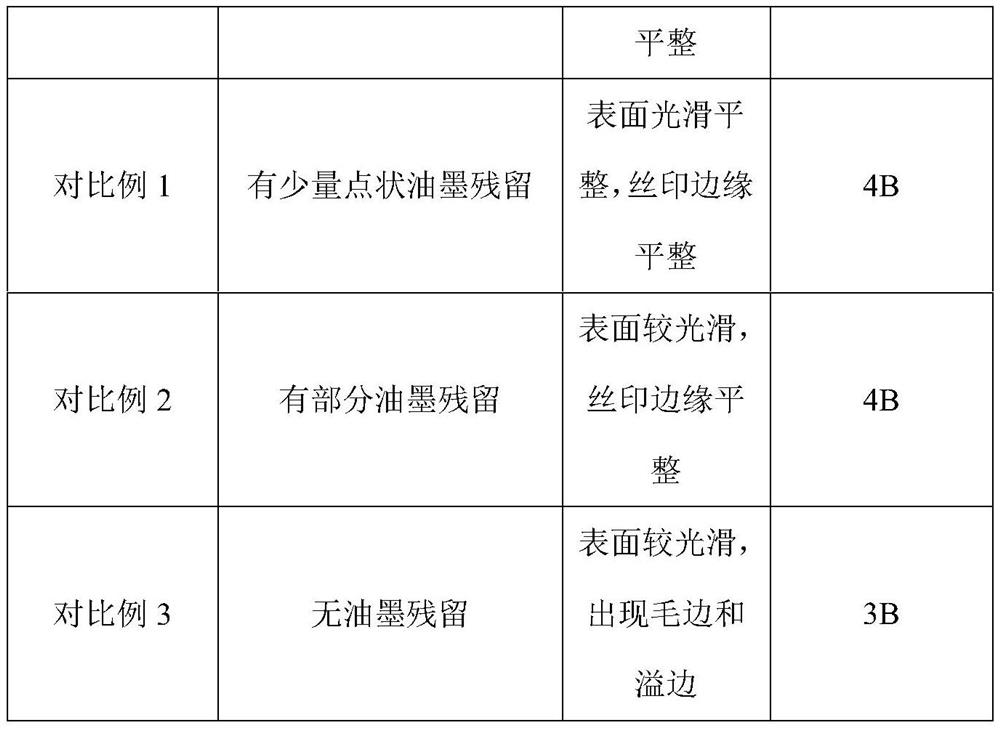

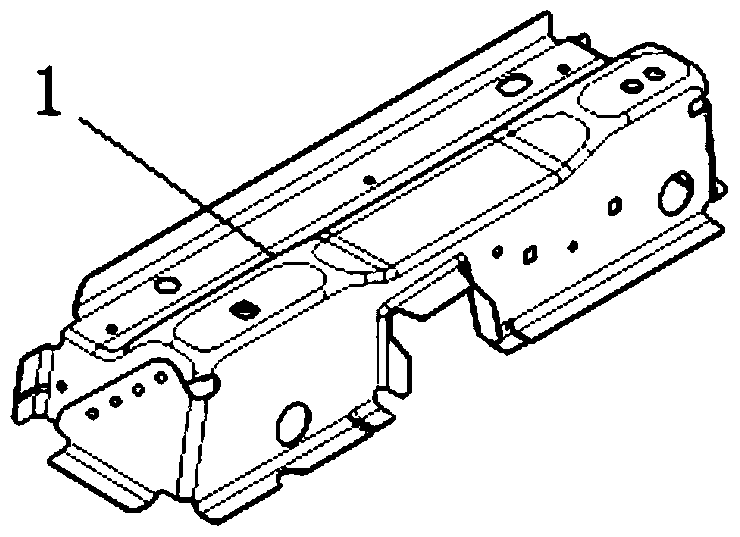

A hot-bending protective forming process for cover plate

ActiveCN111716688BReduce embossingReduce stampingGlass reforming apparatusCoatingsStructural engineeringSurface cover

The invention relates to the technical field of production of curved cover plates, and in particular discloses a hot-bending protection molding process for cover plates, in which ink is applied on the cover plate to form an ink protective layer; the cover plate coated with the ink protective layer Put it into the hot bending mold, use the hot bending equipment to process the hot bending mold so that the cover plate in the hot bending mold becomes a curved protective cover; wash off the ink protective layer on the curved protective cover, so that the curved protective cover The plate becomes a curved cover plate; through the protection of the ink protective layer during the hot bending forming process of the cover plate, it reduces the imprinting, mold printing, and surface pitting caused by the extrusion of the hot bending mold on the cover plate, and reduces the exposure of the cover plate scratches, improve the production yield of the curved cover, and reduce the production cost of the curved cover.

Owner:东莞市铂华光电材料有限公司

Seat frame, production method of seat frame, and automobile

InactiveCN106740286BReduce manufacturing costReduce stampingVehicle seatsCar seatMechanical engineering

The invention provides a seat support, a production method for the seat support and an automobile. The seat support comprises a seat bearing plate, a first support structure and a second support structure which are formed in a rolled mode, wherein the first support structure is fixedly arranged at the first end of the seat bearing plate, and the second support structure is fixedly arranged at the second end of the seat bearing plate which is opposite to the first end. The seat support, the production method for the seat support and the automobile can be completed only by a set of rolling mould, and therefore the processes of pressing, bending and the self-welding of the part are saved, and the production cost of the seat support is reduced.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Metal middle frame structure processing technology, metal middle frame structure and electronic equipment

ActiveCN107087366BReduce processing timeIncrease productivityCasings/cabinets/drawers detailsStampingManufactured material

The invention relates to a metal middle frame structure, an electronic device with the metal middle frame structure and a metal middle frame structure processing technique. Welding moulding technique is performed on the metal frame, so material waste caused by machining allowance of the metal frame is reduced; the proportion of raw material cost in the total manufacturing cost is reduced; middle stamping, CNC processing and heat treatment procedures are reduced; processing time of the metal frame is reduced; production efficiency of the whole metal frame structure is improved; manufacturing cost of the electronic device is reduced through large-scale production; and market competitiveness of the metal middle frame is improved.

Owner:GUANGDONG EVERWIN PRECISION TECH

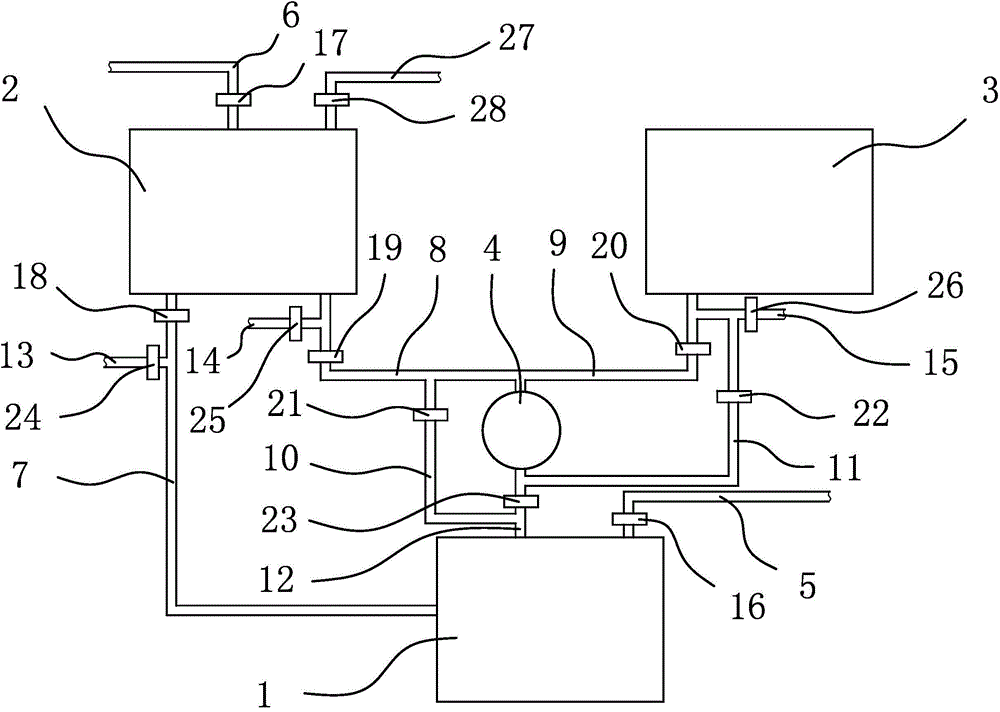

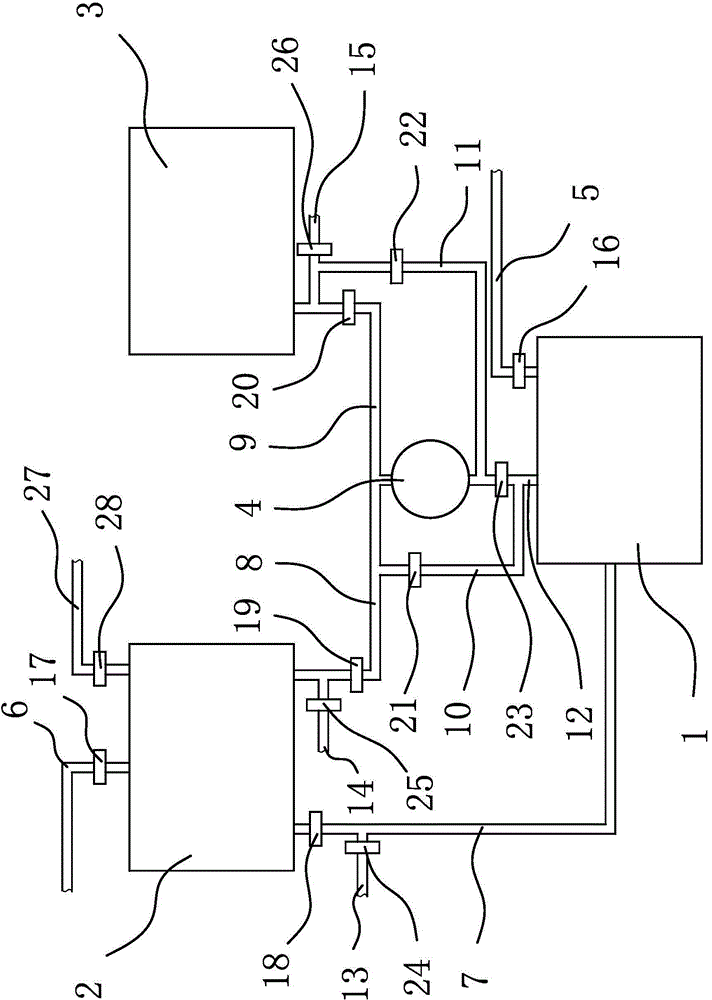

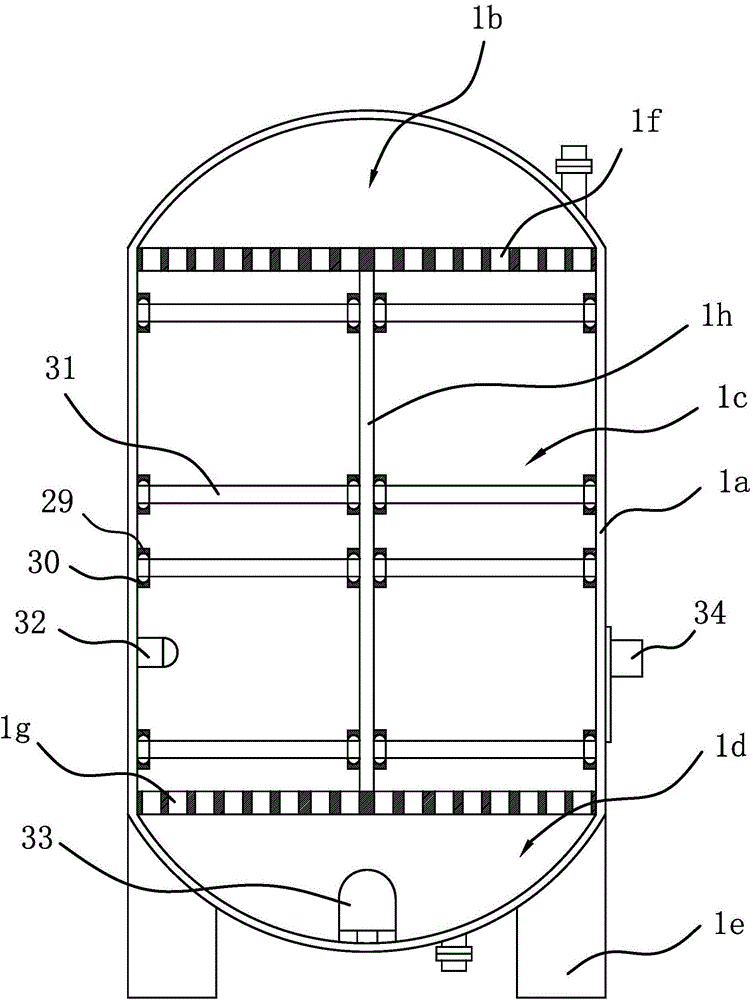

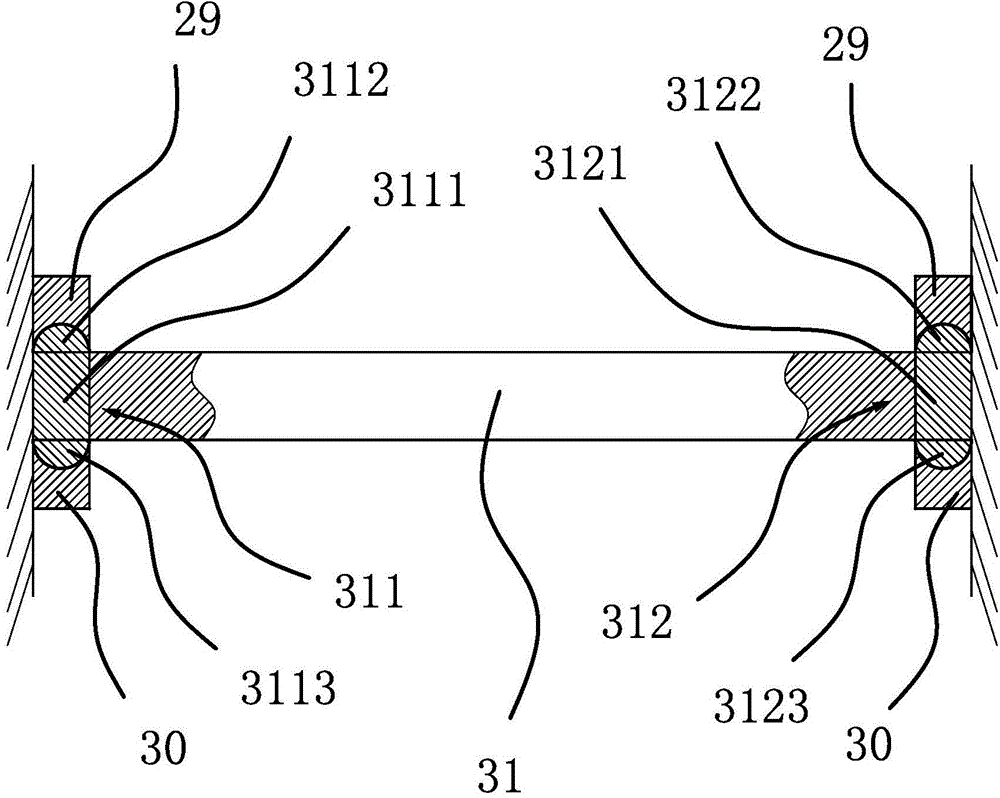

Dye vat water circulation system of improved structure

ActiveCN104862915AAchieve recyclingSave waterTextile treatment containersTextile treatment machine arrangementsYarnWater resources

Owner:ZHEJIANG YINGSHANHONG TEXTILE TECH CO LTD

A water circulation system for a dye vat

ActiveCN103774369BAchieve recyclingSave waterTextile treatment machine arrangementsYarnWater resources

The invention provides a water circulation system of a dye vat and belongs to the technical field of printing and dyeing equipment. The water circulation system can be used for solving the problem of serious water resource wastes during yarn dyeing in the printing and dyeing industry. The water circulation system of the dye vat comprises the dye vat, a cold water vat and a hot water vat, and is characterized in that the dye vat is connected with a water feeding mechanism capable of providing cold water to the dye vat; the hot water vat is connected with a water replenishing mechanism capable of replenishing hot water to the hot water vat; a connecting pipe III is communicated between the dye vat and the hot water vat; the hot water vat is communicated with a water inlet pipe of a water pump by virtue of a connecting pipe IV; a water outlet pipe of the water pump is communicated with the dye vat by virtue of a connecting pipe VIII; a connecting pipe VI is communicated between the connecting pipe IV and the connecting pipe VIII; the cold water vat is communicated with the water inlet pipe of the water pump by virtue of a connecting pipe V; a connecting pipe VII is communicated between the connecting pipe V and the connecting pipe VIII. The water circulation system can be used for recycling dirty water during yarn printing and dyeing, and saving water resources.

Owner:ZHEJIANG YINGSHANHONG TEXTILE TECH CO LTD

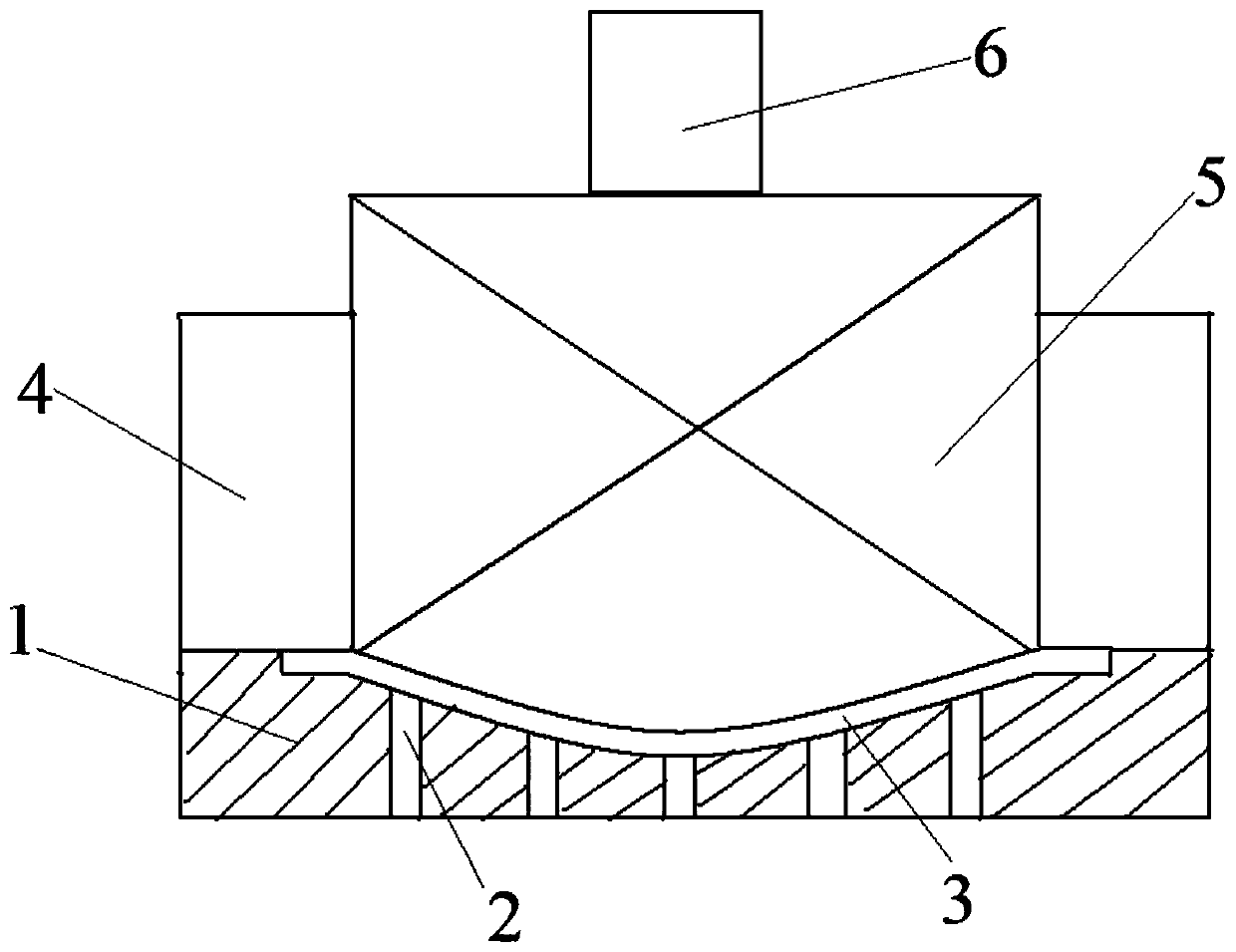

Production process of 3D curved glass panel

InactiveCN111003928AReduce stampingAvoid subsequent polishing stepsGlass reforming apparatusStructural engineeringManufacturing engineering

The invention discloses a production process of a 3D curved glass panel, and the method comprises the following steps: S01, placing plain glass on a female die, and fixing the periphery of the plain glass by using a frame body frame; s02, heating the female die for softening the plain glass; s03, allowing a driving mechanism to drive a forming block to move downwards along the frame body frame toextrude the plain glass; s04, vacuumizing the female die through a vent hole in the female die to form curved glass; and S05, cooling the curved glass until the curved glass is shaped. According to the production process of the 3D curved glass panel, mold marks appearing on the lower surface of the curved glass in the forming process can be reduced, and the subsequent polishing procedure is avoided.

Owner:苏州市灵通玻璃制品有限公司

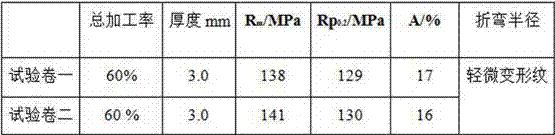

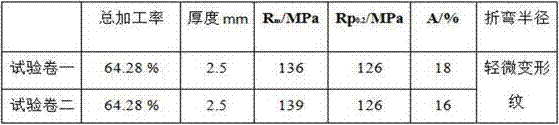

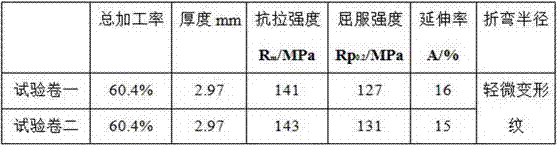

A kind of 1100‑h24 aluminum alloy plate for car door

ActiveCN105543573BHigh bake hardening propertiesRaise the percentage contentPunchingChemical composition

The invention provides an 1100-H24 aluminum alloy plate strip used for a car door and a preparation method thereof. The preparation method comprises the following steps of casting, sawing, milling, homogenization heat treatment, hot rolling, blank annealing, cold rolling, cleaning and finished product annealing. The aluminum alloy plate strip comprises, by mass, 0.35-0.40% of Si, 0.45- 0.50% of Fe, 0.15- 0.20% of Cu, less than 0.05% of Mn, less than 0.05% of Mg, less than 0.05% of Cr, less than 0.05% of Zn, 0.02-0.025% of Ti, and the balance aluminum. According to the production method, the good stability of the mechanical property of the 1100-H24 aluminum alloy plate strip used for the car door can be ensured, the processing formability of the 1100-H24 aluminum alloy plate strip is also greatly improved in the punching process, the rate of finished products is high, and the production efficiency is greatly improved.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com