A plate sorting mechanism

A plate and sorting technology, used in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problem of troublesome single-piece extraction of plates, and achieve the effects of low labor cost, improved production efficiency, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

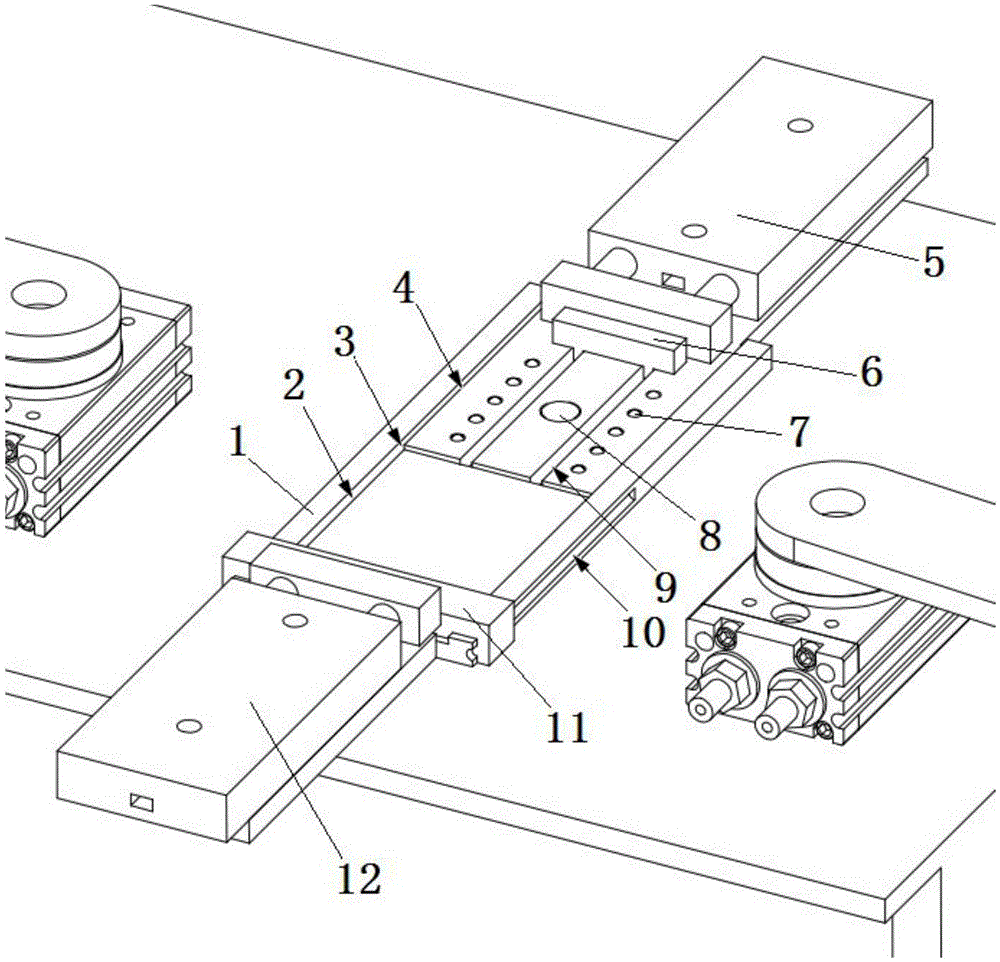

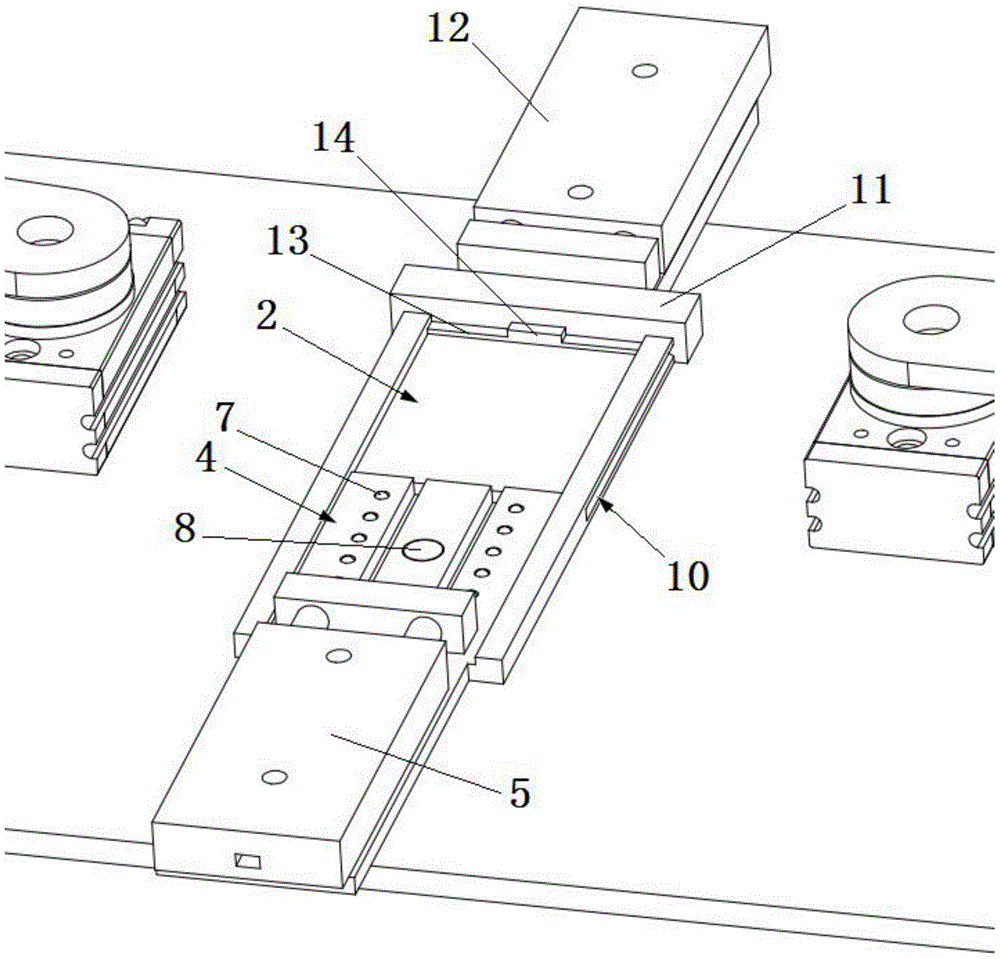

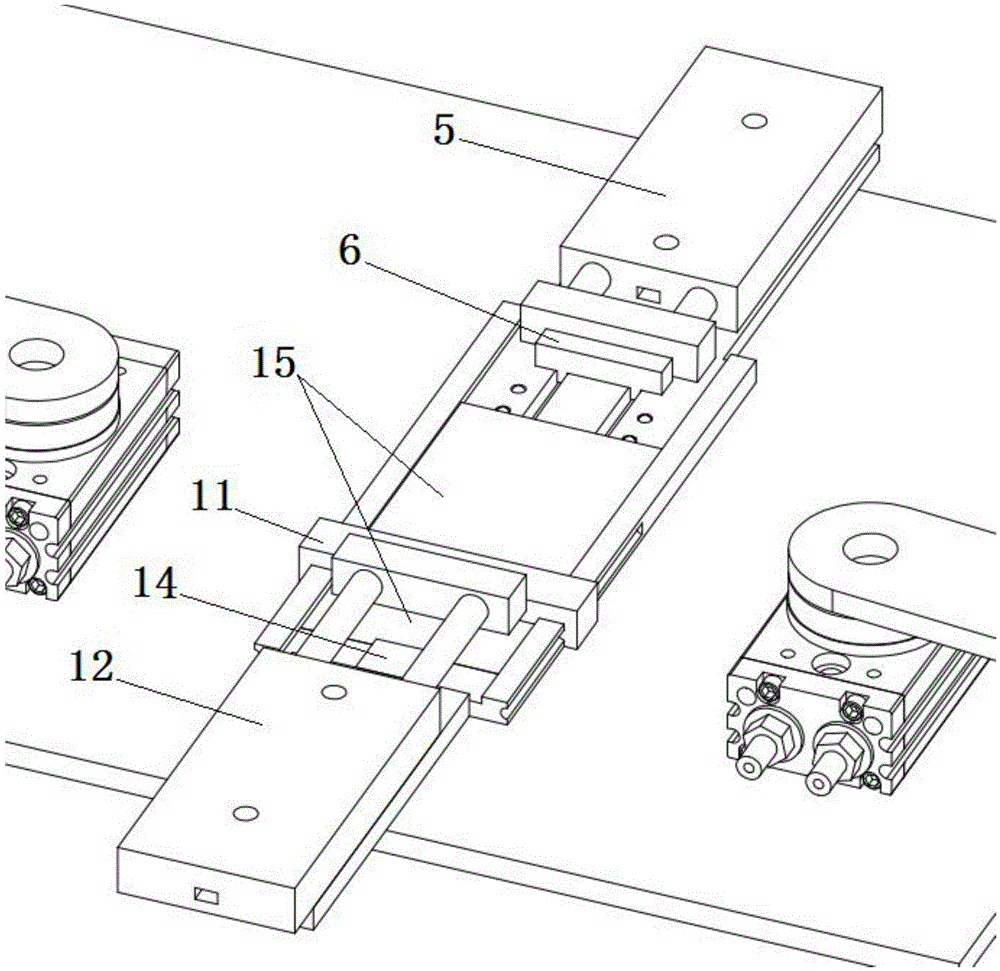

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] A kind of plate sorting mechanism, see figure 1 , figure 2 , including a base plate 1, the base plate 1 is provided with a feed tank 2, the width of the feed tank 2 is the same as the width of the plate 15, and the feed tank 2 is divided into a material distribution area 3 and a material waiting area 4, The material-waiting area 4 is higher than the material-distributing area 3, and the higher height is equal to the thickness of a plate 15, so that when sorting, except the bottom plate 15, all the other plates 15 are pushed to the material-waiting area 4; On the said distributing area 3, be provided with a retaining wall 13 on the side opposite to the waiting area 4, the retaining wall 13 is also equal to the thickness of a plate 15, the retaining wall 13 is provided with a stopper 14, and the retaining block 14 reaches the distributin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com