A kind of 1100‑h24 aluminum alloy plate for car door

An aluminum alloy plate and aluminum alloy technology, which is applied in the field of aluminum alloy, can solve the problems of large amount of internal slag inclusion, unstable processing and forming performance of stamping products, and low yield rate, so as to improve product performance, improve bake hardening performance, The effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

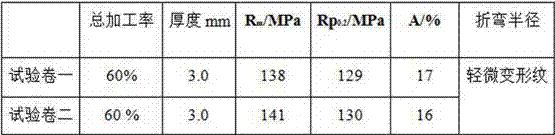

Embodiment 1

[0033] A 1100-H24 aluminum alloy plate for a car door, the chemical composition mass percentage of the aluminum alloy plate is: Si0.350%, Fe 0.477%, Cu 0.176%, Mn 0.007%, Mg 0.003%, Cr 0.002%, Zn 0.004% , Ti 0.020%, the rest is Al.

[0034] The production method of the 1100-H24 aluminum alloy plate for the car door comprises the following steps:

[0035] (1) Smelting and casting: Add aluminum ingots into the melting furnace, obtain aluminum ingot solution at a melting temperature of 720~750°C, and a refining temperature of 720~750°C, then add Si, Fe, and Cu to obtain an aluminum alloy plate that meets the chemical requirements of the aluminum alloy sheet. The composition of the aluminum alloy solution, casting an aluminum alloy ingot with a thickness of 600mm and a width of 1350mm from the aluminum alloy solution at a casting temperature of 715~730°C and a casting speed of 45~50mm / min;

[0036] (2) Saw cutting and face milling: Use a milling machine to mill the large and small ...

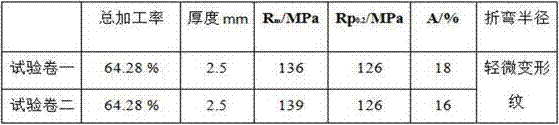

Embodiment 2

[0050] A 1100-H24 aluminum alloy plate for a car door, the chemical composition mass percentage of the aluminum alloy plate is: Si0.366%, Fe 0.450%, Cu 0.176%, Mn 0.0058%, Mg 0.0018%, Cr 0.0013%, Zn 0.011% , Ti0.024%, the rest is Al.

[0051] The production method of the 1100-H24 aluminum alloy plate for the car door comprises the following steps:

[0052] (1) Smelting and casting: Add aluminum ingots into the melting furnace, obtain aluminum ingot solution at a melting temperature of 720~750°C, and a refining temperature of 720~750°C, then add Si, Fe, and Cu to obtain an aluminum alloy plate that meets the chemical requirements of the aluminum alloy sheet. The composition of the aluminum alloy solution, casting an aluminum alloy ingot with a thickness of 600mm and a width of 1350mm from the aluminum alloy solution at a casting temperature of 715~730°C and a casting speed of 45~50mm / min;

[0053] (2) Sawing and face milling: using a milling machine to mill the large and small...

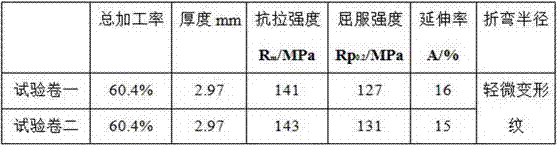

Embodiment 3

[0067] A 1100-H24 aluminum alloy plate for a car door, the chemical composition mass percentage of the aluminum alloy plate is: Si0.398%, Fe 0.50%, Cu 0.15%, Mn 0.0056%, Mg 0.0018%, Cr 0.0013%, Zn 0.011% , Ti0.021%, the rest is Al.

[0068] The production method of the aluminum alloy plate for the 1100-H24 car door comprises the following steps:

[0069] (1) Smelting and casting: Add aluminum ingots into the melting furnace, obtain aluminum ingot solution at a melting temperature of 720~750°C, and a refining temperature of 720~750°C, then add Si, Fe, and Cu to obtain an aluminum alloy plate that meets the chemical requirements of the aluminum alloy sheet. The composition of the aluminum alloy solution, casting an aluminum alloy ingot with a thickness of 600mm and a width of 1350mm from the aluminum alloy solution at a casting temperature of 715~730°C and a casting speed of 45~50mm / min;

[0070] (2) Sawing and face milling: using a milling machine to mill the large and small f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com