A kind of aluminum alloy sheet for automobile body and preparation method thereof

A technology for aluminum alloy sheets and automobile bodies, applied in the field of aluminum alloy materials, can solve the problems of unfavorable sheet stamping, high yield strength, and insignificant effects, and achieve the advantages of eliminating paint brush lines, high surface quality, and excellent hemming performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

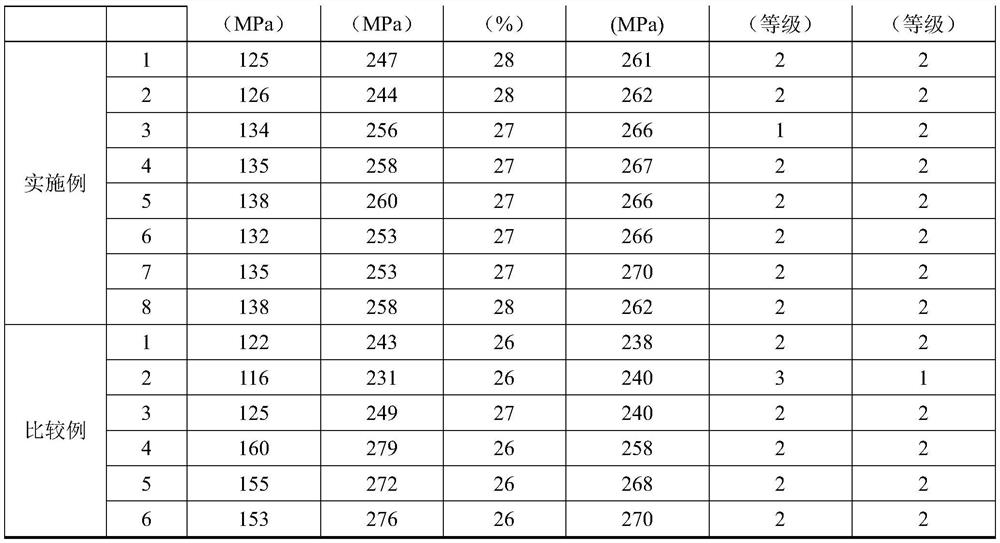

Examples

Embodiment 1

[0035] The composition of the aluminum alloy is calculated by mass percentage: Si: 0.8wt.%; Mg: 0.8wt.%; Zn: 0.4wt.%; Cu: 0.2wt.%; Mn: 0.1wt.%; Zr: 0.1wt.% ; Fe: ≤0.2wt.%, the balance is Al and normal impurities.

[0036]The alloy is melted according to the above ratio, and the melt is refined (filtered by a 50ppi filter plate with a pore size, degassed with argon gas online, and the hydrogen content is controlled to 0.13ml / 100g Al), and then the ingot is cast by semi-continuous casting equipment; After the ingot is cut and face milled, it is homogenized. The homogenization temperature is 550°C and the temperature is kept for 10 hours. After that, the temperature is lowered to 520°C for hot rolling, and the rolling is to 6mm thick. The final rolling temperature is 260°C; three passes of cold Roll to 3.3mm, then perform intermediate annealing and cold rolling at 440°C×5h to obtain a cold-rolled sheet with a thickness of 1mm, keep the cold-rolled reduction rate of the sheet afte...

Embodiment 2

[0038] The composition of aluminum alloy is calculated by mass percentage: Si: 1.0wt.%; Mg: 0.55wt.%; Zn: 0.6wt.%; Cu: 0.3wt.%; Mn: 0.1wt.%; Zr: 0.1wt.% ; Fe: 0.18wt.%, the balance is Al and normal impurities.

[0039] The alloy is melted according to the above ratio, and after the melt is refined, the ingot is cast by semi-continuous casting equipment; the ingot is homogenized after being cut and milled, and the homogenization temperature is 550°C, and the temperature is kept for 10 hours ; After cooling down to 500°C for hot rolling and starting rolling, rolling to 5mm thick, the final rolling temperature is 270°C; cold rolling to 1.43mm, and then 430°C×5h intermediate annealing and cold rolling to obtain a 1mm thick cold-rolled sheet, keep the annealed The plate is cold-rolled to the final thickness. The cold-rolling reduction rate of the plate is 30%, followed by solution treatment. The solution treatment temperature is 550°C, and the holding time is 90s. After that, it is...

Embodiment 3

[0041] The composition of aluminum alloy is calculated by mass percentage: Si: 1.2wt.%; Mg: 0.3wt.%; Zn: 0.8wt.%; Cu: 0.1wt.%; Mn: 0.1wt.%; Zr: 0.1wt.% ; Fe: 0.18wt.%, the balance is Al and normal impurities.

[0042] The alloy is melted according to the above ratio, and after the melt is refined, the ingot is cast by semi-continuous casting equipment; the ingot is homogenized after being cut and milled, and the homogenization temperature is 550°C, and the temperature is kept for 10 hours ; After cooling down to 500°C, hot rolling starts rolling, rolling to 6mm thick, and final rolling temperature at 260°C; cold rolling to 4mm, and then 440°C×4h intermediate annealing and cold rolling to obtain a 1mm thick cold-rolled sheet, keep the sheet after annealing The cold rolling reduction rate of cold rolling to the final thickness of the plate is 80%, followed by solution treatment, the solution treatment temperature is 560 ° C, the holding time is 60s, and then cooled, and the stra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com