Al-Mg-Si alloy plate and manufacturing method thereof

A technology of al-mg-si and alloy plates, which is applied in the field of aluminum alloy plates and its manufacturing, can solve problems such as low strength, failure to meet the requirements of automobile factories, and low strength increments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

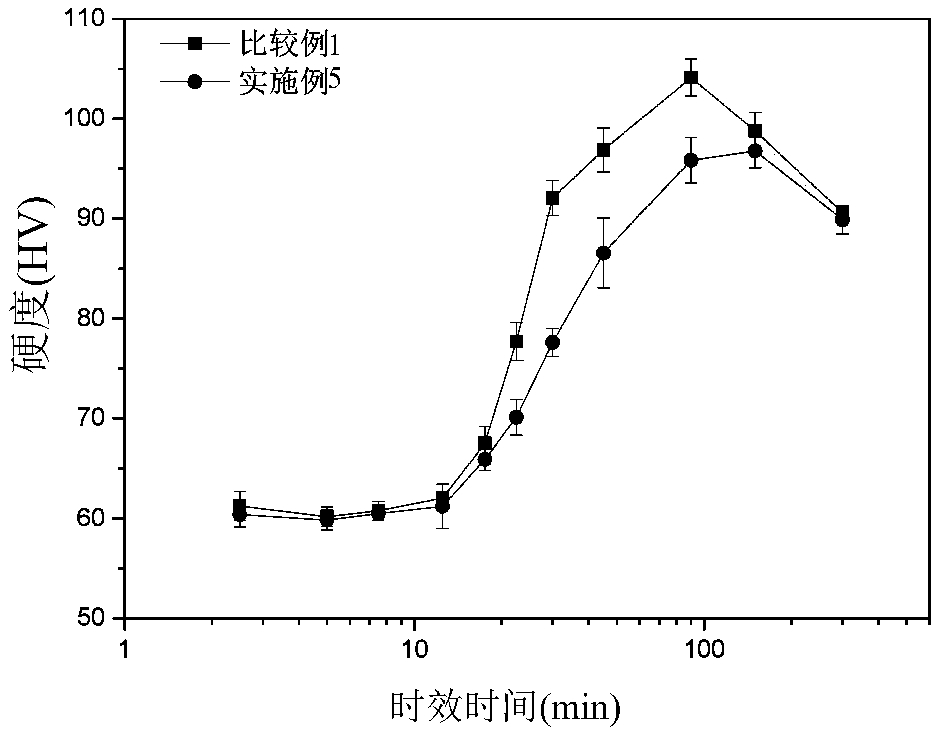

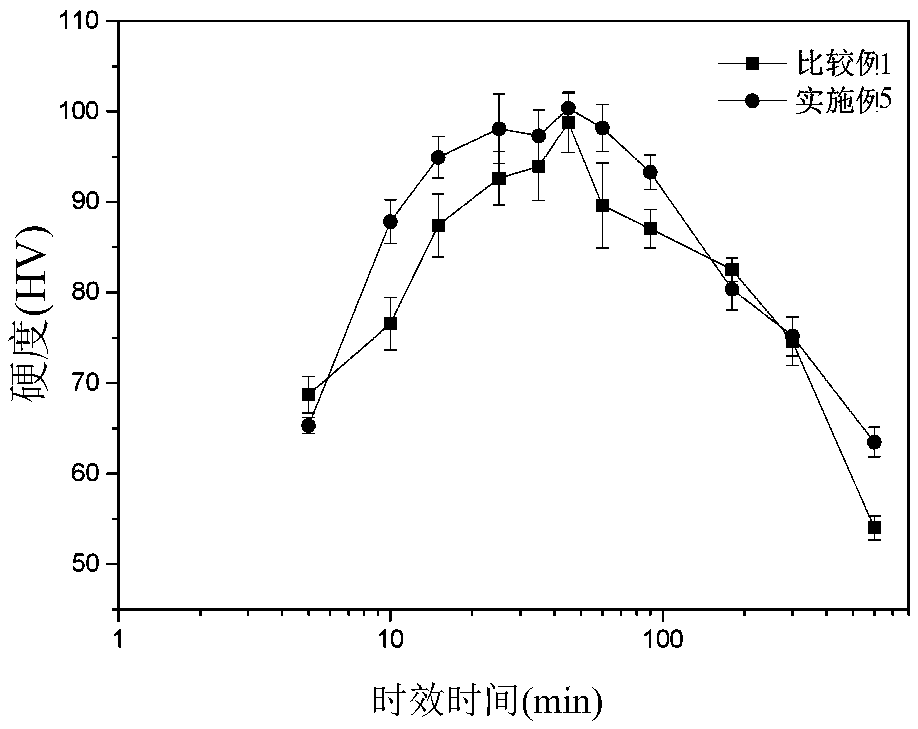

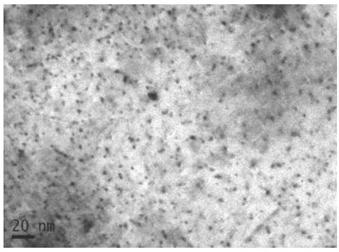

Examples

Embodiment 1-6 and comparative example 1-2

[0066] Table 1 lists the mass percentage (wt%) of each chemical element in the Al-Mg-Si alloy sheets of Examples 1-6 and Comparative Examples 1-2.

[0067] Table 1. (wt%, the balance is Al and other unavoidable impurity elements except Cr and Zn)

[0068]

[0069] The manufacturing method of the Al-Mg-Si alloy plate of embodiment 1-6 and comparative example 1-2 is as follows (concrete process parameter is listed in table 2-1, table 2-2 and table 2-3):

[0070] (1) Melting and casting: According to the ratio of the chemical elements listed in Table 1, alloying elements and refiners are added to the industrial aluminum melt for smelting, wherein the alloying elements can be added by adding Al-Si master alloy, pure Cu, Al -Mn master alloy or Mn agent, pure Mg is added to the industrial aluminum melt, and the semi-continuous casting method is selected to rapidly cool from the liquidus temperature to the solidus temperature at a cooling rate of not less than 100°C per minute, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com