High-temperature-resistant protective ink and preparation method thereof

A technology for protecting ink and high temperature resistance, applied in the field of ink printing, can solve problems such as dirt and defects, increase production costs, affect glass appearance, processing efficiency and product yield, and achieve smoothness, easy cleaning, and less polishing requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

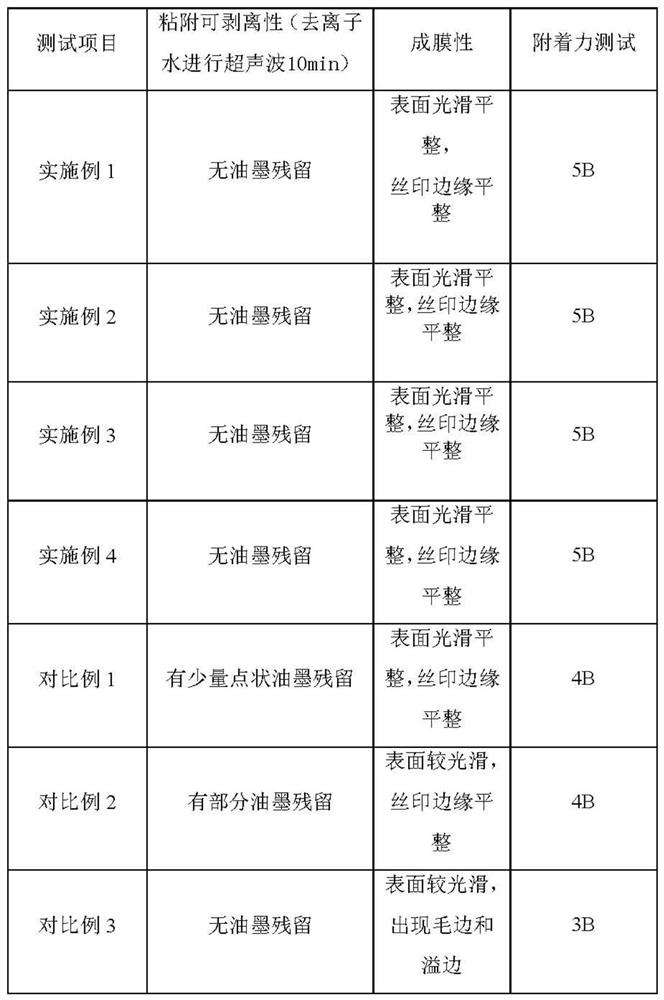

Examples

Embodiment 1

[0033] In this embodiment, a high temperature resistant protective ink comprises the following raw materials in parts by weight: 38 parts of component A, 5 parts of silicon dioxide, 30 parts of calcium sulfate crystals, 2 parts of rutile titanium, 10 parts of PTFE, 13 parts of talcum powder, 1 part of leveling agent, 1 part of defoamer;

[0034] Each part of component A includes the following raw materials in parts by weight: 46 parts of modified acrylic resin, 24 parts of deionized water, 11 parts of absolute ethanol, 5 parts of butyl glycol ether, 0.4 part of organic acid, and 0.5 part of emulsifier , 4 parts of hydrogen peroxide.

[0035] Further, the leveling agent is composed of polyether-modified polysiloxane and polymethylphenylsiloxane in a mass ratio of 1:1.5. The polyether modified polysiloxane is preferably but not limited to BYK-333 leveling agent from Germany.

[0036] Further, the defoamer is composed of polydimethylsiloxane, fluorinated silicone oil and octylp...

Embodiment 2

[0051] In this embodiment, a high temperature resistant protective ink includes the following raw materials in parts by weight: 36 parts of component A, 4 parts of silicon dioxide, 28 parts of calcium sulfate crystals, 1.6 parts of rutile titanium, 8 parts of PTFE, and 11 parts of talcum powder , 0.7 parts of leveling agent, 1.3 parts of defoamer;

[0052] Each part of component A includes the following raw materials in parts by weight: 44 parts of modified acrylic resin, 22 parts of deionized water, 10 parts of absolute ethanol, 4 parts of butyl glycol ether, 0.2 part of organic acid, and 0.2 part of emulsifier , 1 part hydrogen peroxide.

[0053] Further, the leveling agent is composed of polyether-modified polysiloxane and polymethylphenylsiloxane in a mass ratio of 1:0.8.

[0054] Further, the defoamer is composed of polydimethylsiloxane, fluorinated silicone oil and octylphenol polyoxyethylene ether in a weight ratio of 1:1:0.5. The organic acid is composed of cinnamic ...

Embodiment 3

[0067] In this embodiment, a high temperature resistant protective ink includes the following raw materials in parts by weight: 40 parts of component A, 6 parts of silicon dioxide, 32 parts of calcium sulfate crystals, 2.4 parts of rutile titanium, 12 parts of PTFE, and 15 parts of talcum powder , 1.2 parts of leveling agent, 0.7 parts of defoamer;

[0068] Each part of component A includes the following raw materials in parts by weight: 48 parts of modified acrylic resin, 26 parts of deionized water, 12 parts of absolute ethanol, 6 parts of butyl glycol ether, 0.7 part of organic acid, and 0.8 part of emulsifier , 5 parts of hydrogen peroxide.

[0069]Further, the leveling agent is composed of polyether-modified polysiloxane and polymethylphenylsiloxane in a mass ratio of 1:2. The polyether modified polysiloxane is preferably but not limited to BYK-333 leveling agent from Germany.

[0070] Further, the defoamer is composed of polydimethylsiloxane, fluorinated silicone oil a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com