A quick disassembly floating breakwater

A floating breakwater, fast technology, applied in the direction of breakwaters, jetties, embankments, etc., can solve problems such as failure of floating breakwaters, non-recyclability, corrosion of parts, etc., to achieve the effect of improving reuse rate, quick installation, and avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

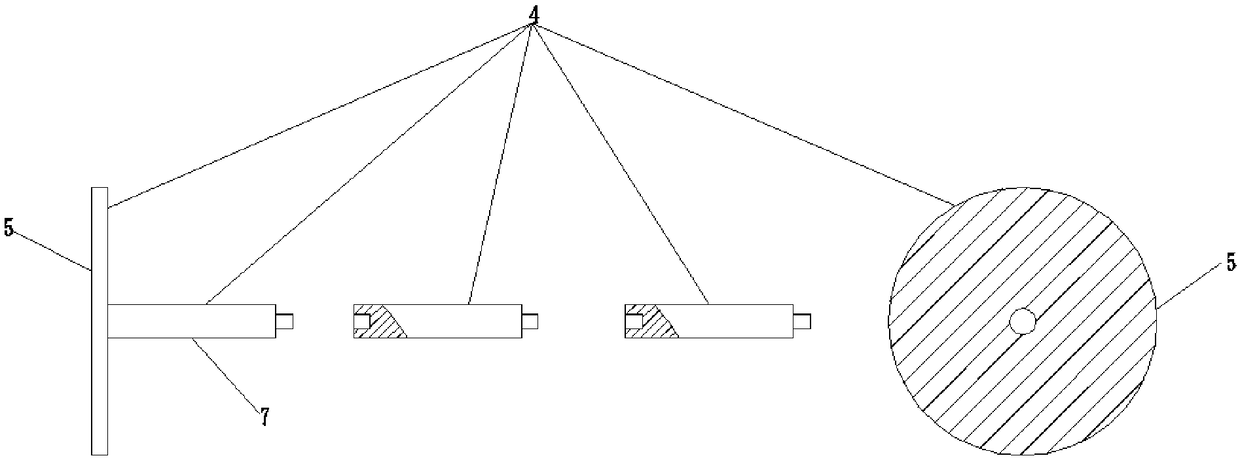

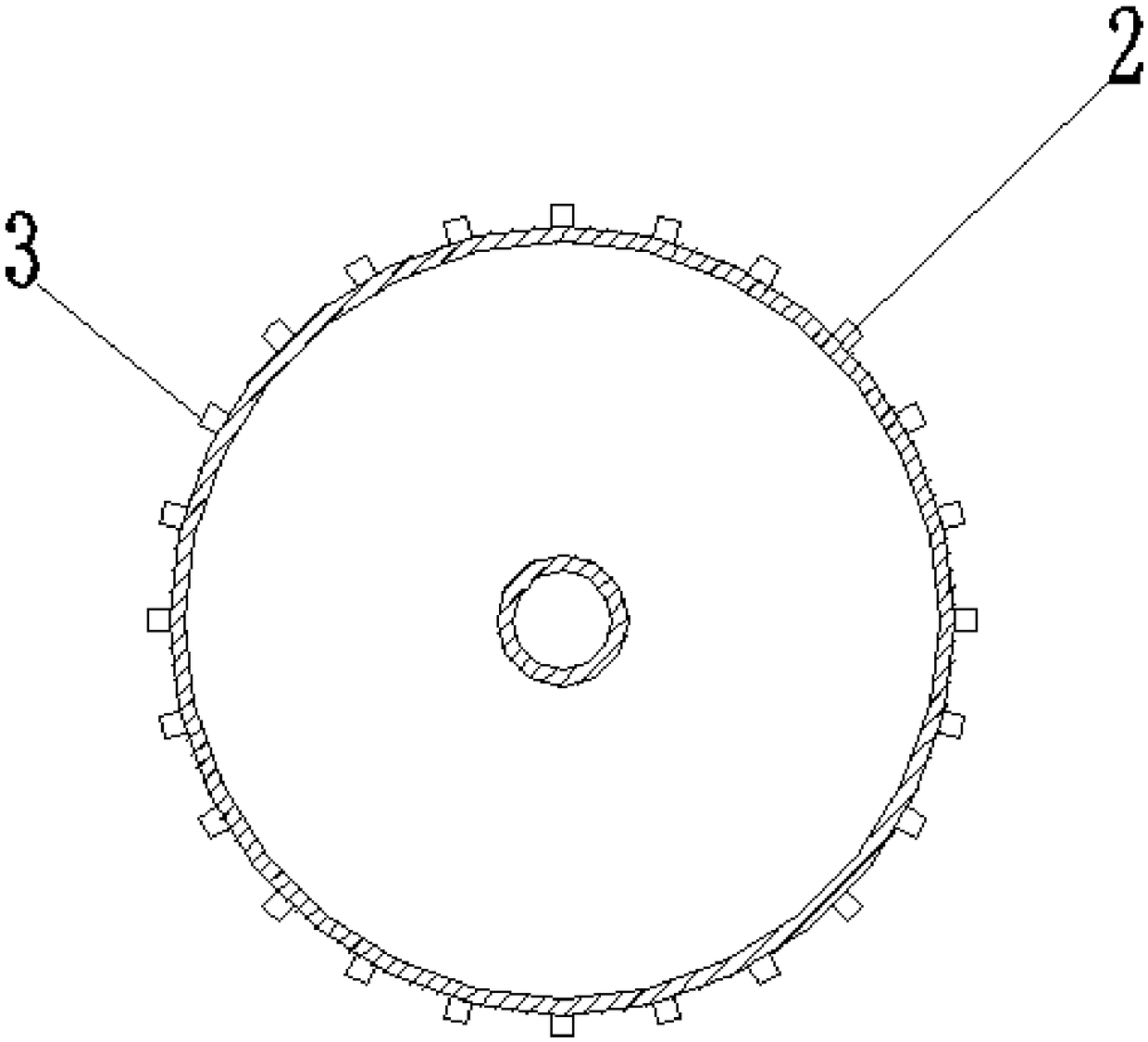

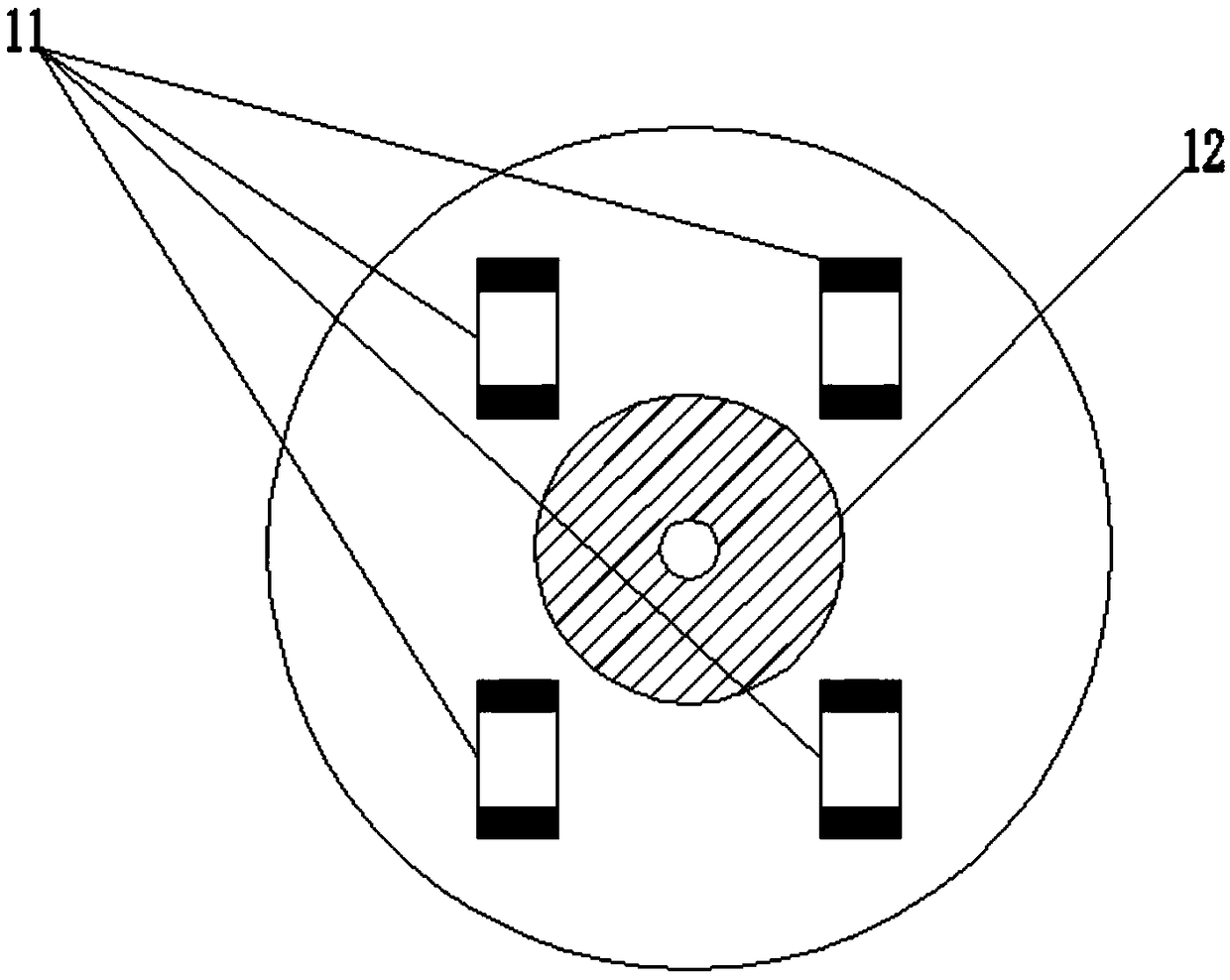

[0021] Such as Figure 1 to Figure 8 As shown, a quick disassembly floating breakwater of the present invention includes several water surface wave-absorbing structural units and mooring systems. The water surface wave-absorbing structural unit includes a cylindrical buoy 1, and each cylindrical buoy 1 is pressed by The load-carrying part, the rubber part of the floating body 2 and the connection device are composed, and the wave-absorbing structural units on the water surface are elastically connected by the connection device, and they move as a whole under the waves to resist the waves.

[0022] In this embodiment, the ballast part 4 of the floating body includes two round covers 5 with the same diameter as the buoy and three steel rod units 7 with the same length and the same diameter. The round covers 5 are circular steel plates, and the cross-section of the solid steel rod is Round shape, one end with built-in thread and the other end with external thread, the round cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com