Super-large diameter shield cutterhead system used in hard-soft heterogeneous ground

A technology with super large diameter and uneven hardness, which is applied in mining equipment, earthwork drilling, tunnels, etc. It can solve the difficulties of large-diameter main bearing processing and manufacturing, poor working stability of the shield machine, and uneven force on the cutterhead, etc. problems, to achieve the effects of excavation in grades of rock and soil, increasing the free surface of rock and soil, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

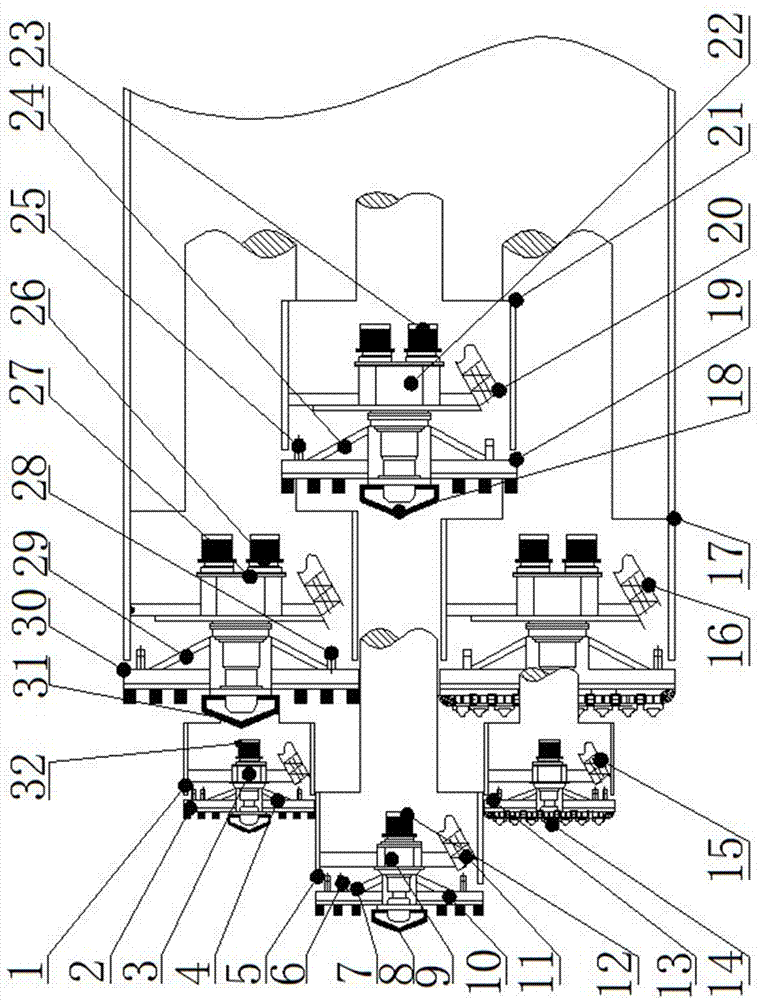

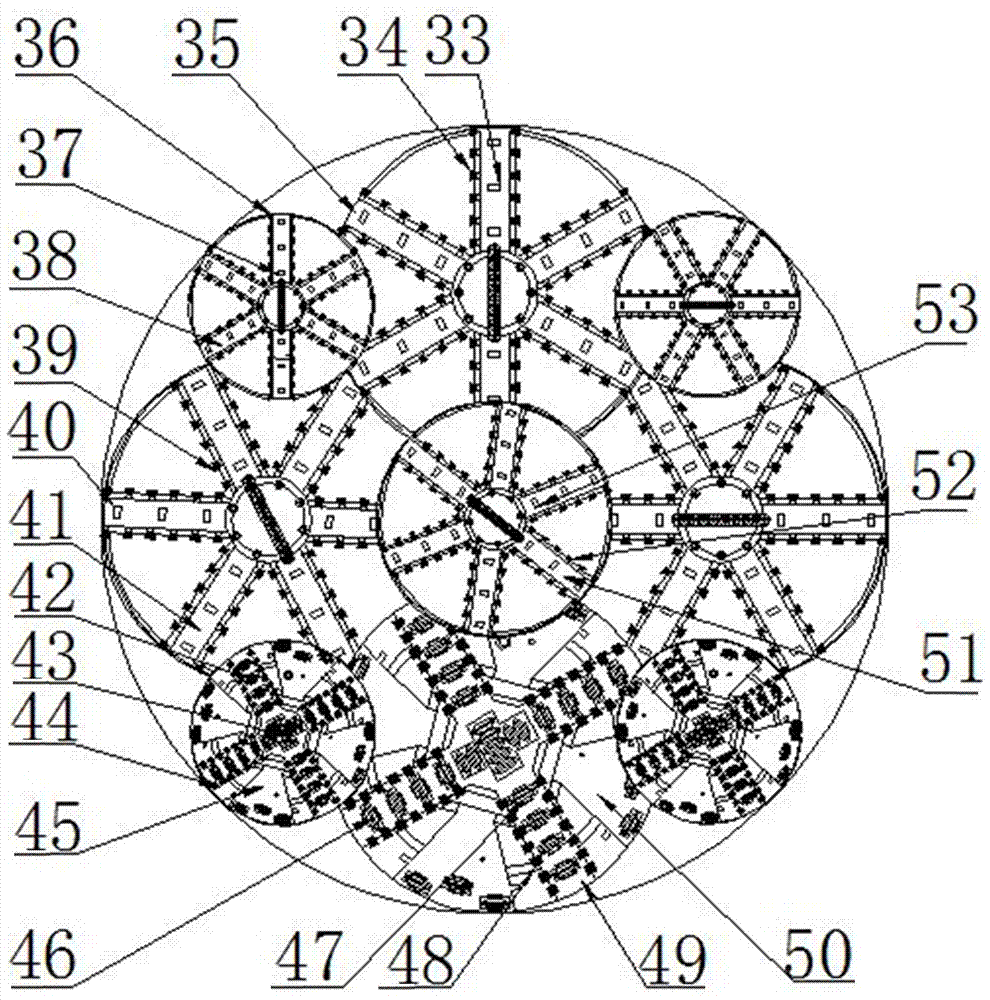

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

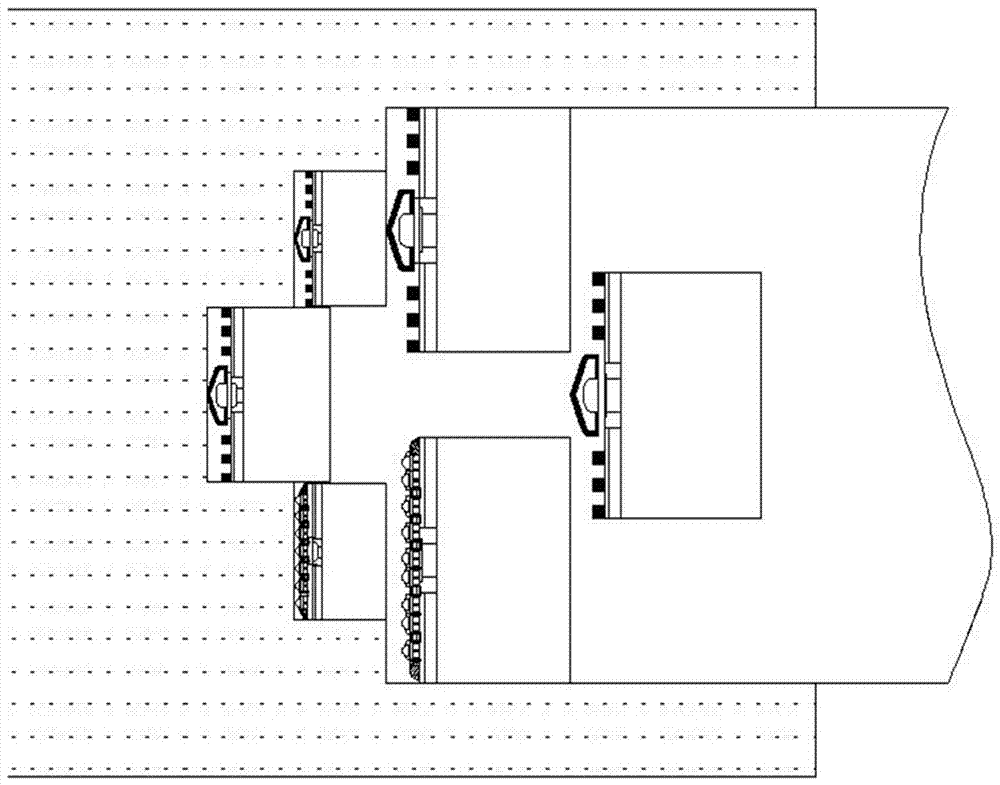

[0023] like figure 1 , figure 2 As shown, a shield cutterhead system with a super large diameter for soft and hard uneven formations includes large cutterheads, medium cutterheads, small cutterheads, spokes, panels, hobs, cutters, leading knives, center knives, stirring Rods, reducers, hydraulic motors, power transmission devices, shields, screw excavation devices. It is characterized in that the front cutterhead structure of the shield machine consists of nine cutterheads distributed in a spatially staggered structure, including large cutterheads, medium-sized cutterheads, and small cutterheads. The first stage of the cutterhead structure is a medium-sized cutterhead, and one medium-sized cutterhead is located at the center of the shield cutterhead structure; the second stage of the cutterhead structure is a small cutterhead, and there are four small cutterheads along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com