A double evaporator alternate defrosting air source heat pump unit and its defrosting method

An air source heat pump and alternate defrosting technology, which is applied to compressors with multiple evaporators, refrigerators, compressors, etc., can solve the problems of low defrosting efficiency, maintaining stability, affecting the heat pump system, etc. Frosting and defrosting loss coefficient, reduced structural complexity, simple and efficient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

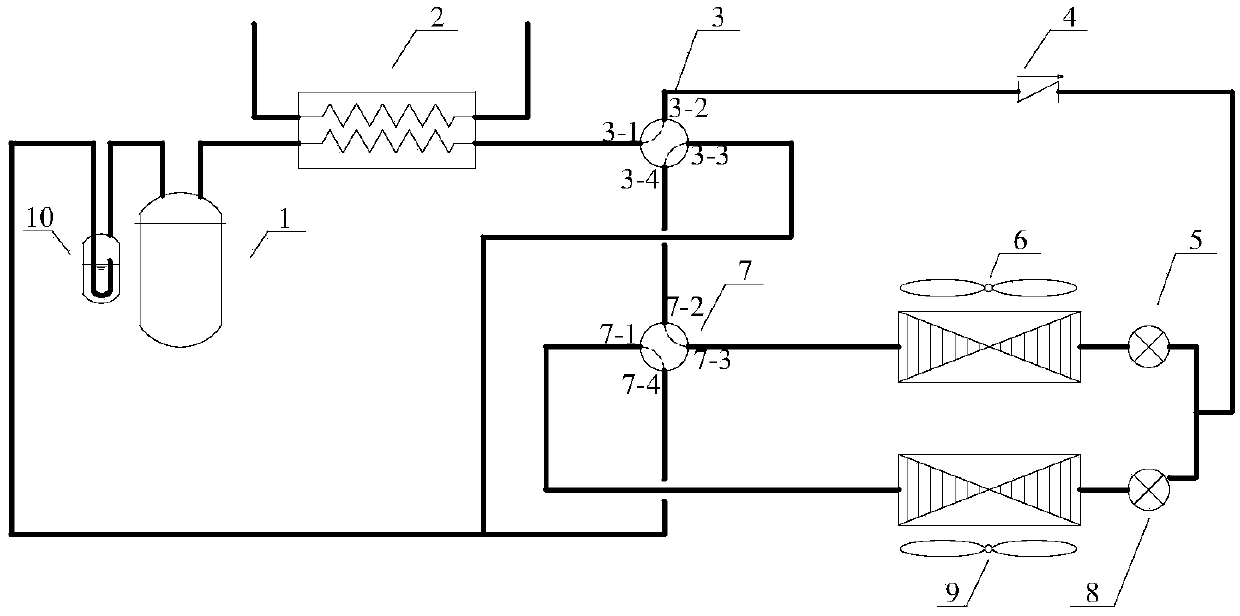

[0032] combine figure 1 , the double evaporator alternate defrosting method and the air source heat pump unit of the present invention switch the evaporator that needs to be defrosted to a subcooler through the function switching of the four-way reversing valve and the throttling mechanism of the system, and use the high-pressure and high-temperature outlet of the condenser The liquid refrigerant melts and removes the frost layer on the surface of the evaporator to achieve the purpose of defrosting; the other air-cooled evaporator absorbs heat from the environment to achieve continuous heating. It includes a compressor 1 for inhaling gaseous refrigerant and compressing and outputting it, a gas-liquid separator 10 whose outlet is connected to the suction port of the compressor 1, a condenser 2 whose inlet is connected to the outlet of the compressor 1, and a second A four-way reversing valve 3, a second four-way reversing valve 7, a one-way valve 4, a first throttle assembly 5,...

Embodiment 2

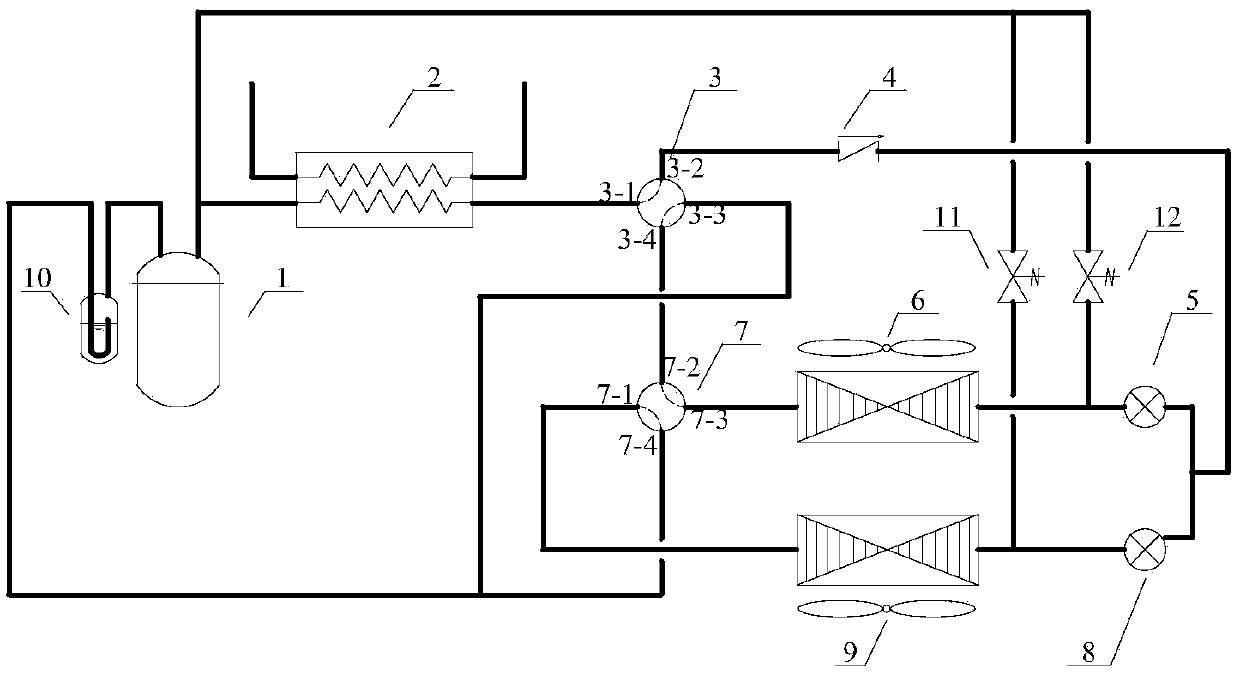

[0044] combine figure 2 , the double evaporator alternate defrosting method and the air source heat pump unit of the present invention switch the evaporator that needs to be defrosted to a subcooler through the function switching of the four-way reversing valve and the throttling mechanism of the system, and use the high-pressure and high-temperature outlet of the condenser The liquid refrigerant melts and removes the frost layer on the surface of the evaporator to achieve the purpose of defrosting; the other air-cooled evaporator absorbs heat from the environment to achieve continuous heating. It includes a compressor 1 for inhaling gaseous refrigerant and compressing and outputting it, a gas-liquid separator 10 whose outlet is connected to the suction port of the compressor 1, a condenser 2, and a first four-way reversing valve 3. The second four-way reversing valve 7, the one-way valve 4, the first energy regulating valve 11, the second energy regulating valve 12, the firs...

Embodiment 3

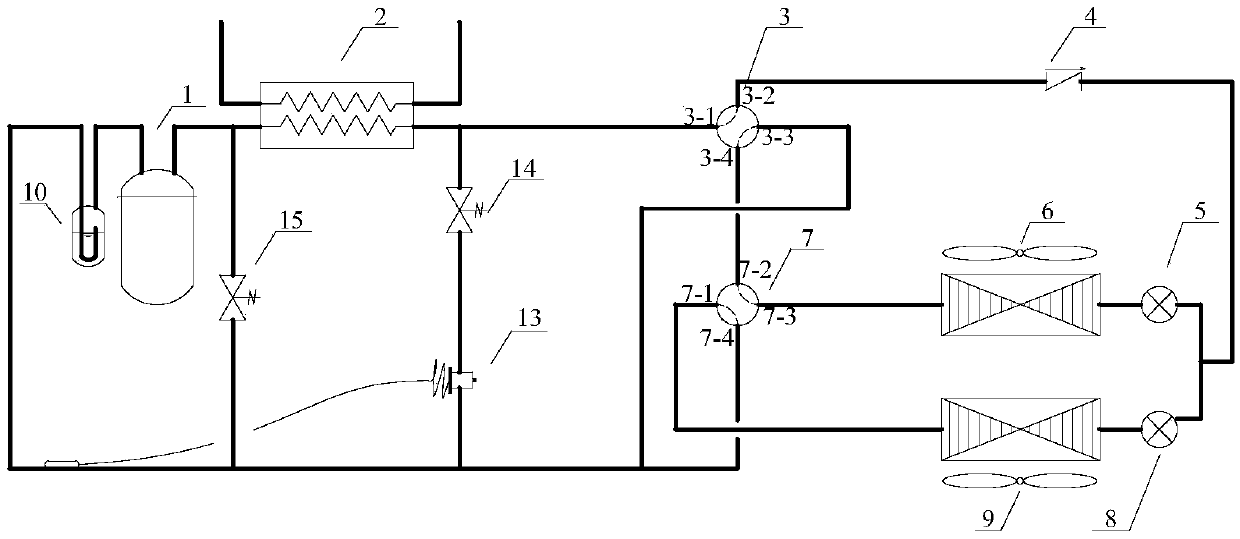

[0056] combine image 3 , the double evaporator alternate defrosting method and the air source heat pump unit of the present invention switch the evaporator that needs to be defrosted to a subcooler through the function switching of the four-way reversing valve and the throttling mechanism of the system, and use the high-pressure and high-temperature outlet of the condenser The liquid refrigerant melts and removes the frost layer on the surface of the evaporator to achieve the purpose of defrosting; the other air-cooled evaporator absorbs heat from the environment to achieve continuous heating. It includes a compressor 1 for inhaling gaseous refrigerant and compressing and outputting it, a gas-liquid separator 10 whose outlet is connected to the suction port of the compressor 1, a condenser 2, a bypass energy regulating valve 15, a Thermal expansion valve 13, solenoid valve 14, first four-way reversing valve 3, second four-way reversing valve 7, one-way valve 4, first throttle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com