Metal component detection method and device based on spectrum analysis technology

A technology for spectral analysis and metal composition, applied in the direction of analyzing materials, instruments, etc., can solve the problem that the repetition frequency cannot be adjusted arbitrarily at the same time, high power, high stability ultra-short pulse laser output, the laser pulse repetition frequency cannot be easily changed, Affecting problems such as mode-locked laser pulses, achieving the effect of fast and convenient automatic detection and analysis, improving pulse drive quality, and reducing difficulty requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

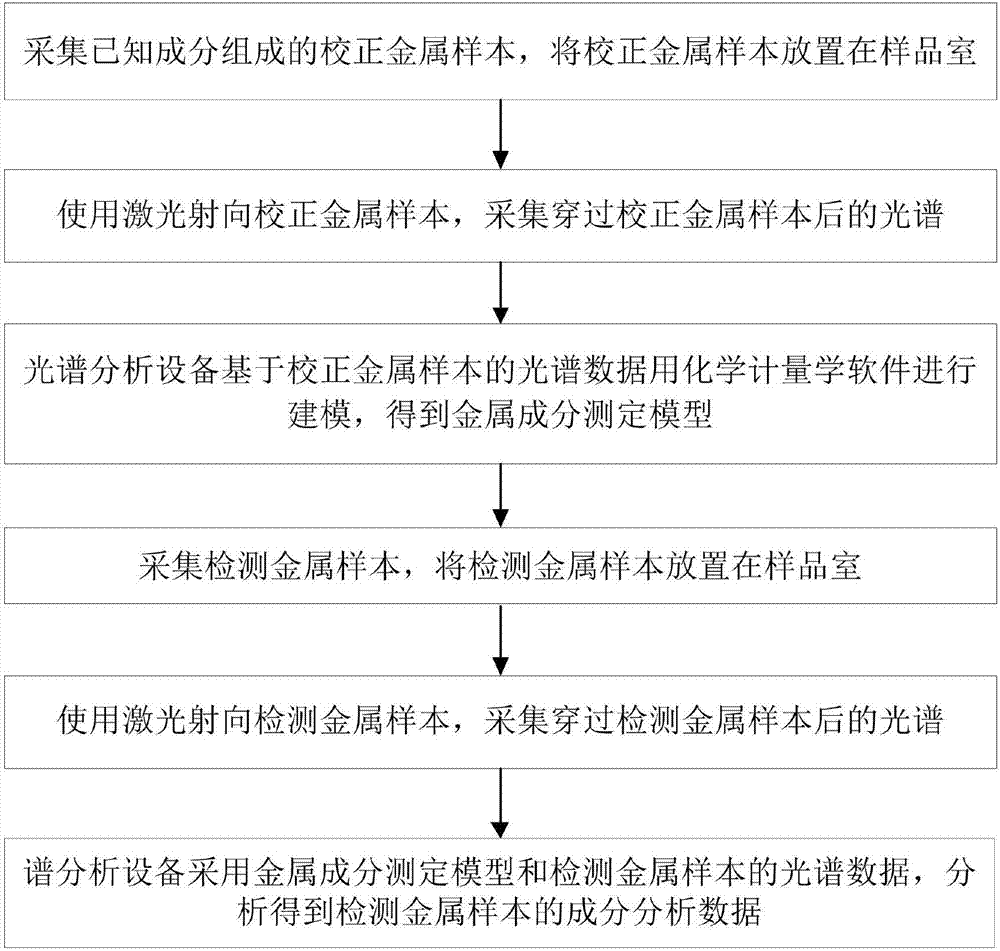

[0061] Such as figure 1 Shown is the flow chart of the metal component detection method based on the spectral analysis technology of the present invention.

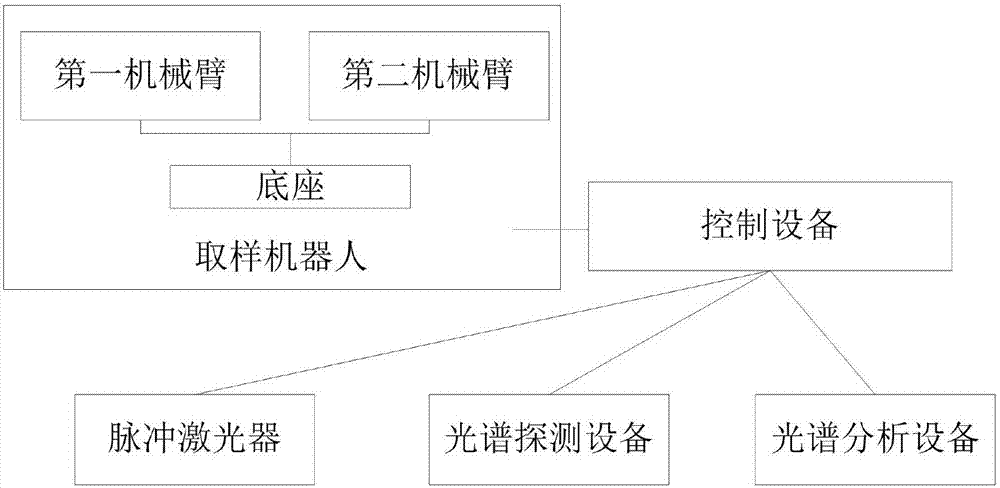

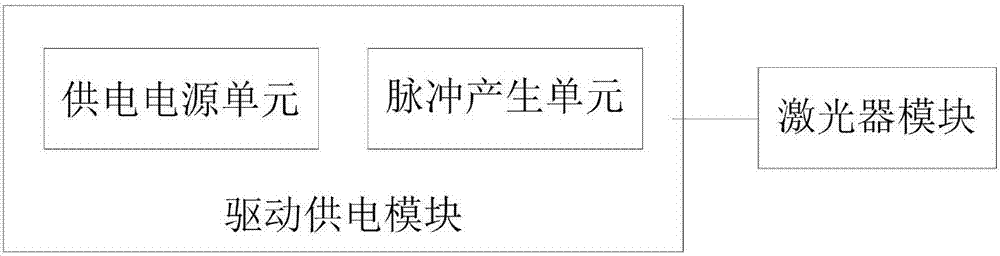

[0062] In the metal component detection method based on spectral analysis technology, the method adopts a metal component detection device, and the device includes a sampling robot, a blower device, a pulse laser, a spectral detection device, a spectral analysis device and a control device, and the pulse laser The ultrashort pulse output end of the pulse laser is opposite to the sample chamber, the ultrashort pulse output end of the pulse laser is aligned with the spectrum collection lens group in the spectrum detection device, the air outlet of the blowing device is aligned with the sample chamber, the The sample chamber includes a tray and a transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com