Pharmaceutical composition and preparation method thereof

A composition and drug technology, applied in the field of oral stable pharmaceutical composition and preparation, can solve the problems of complicated preparation process, influence drug safety, influence product quality, etc. The effect of reducing the economic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

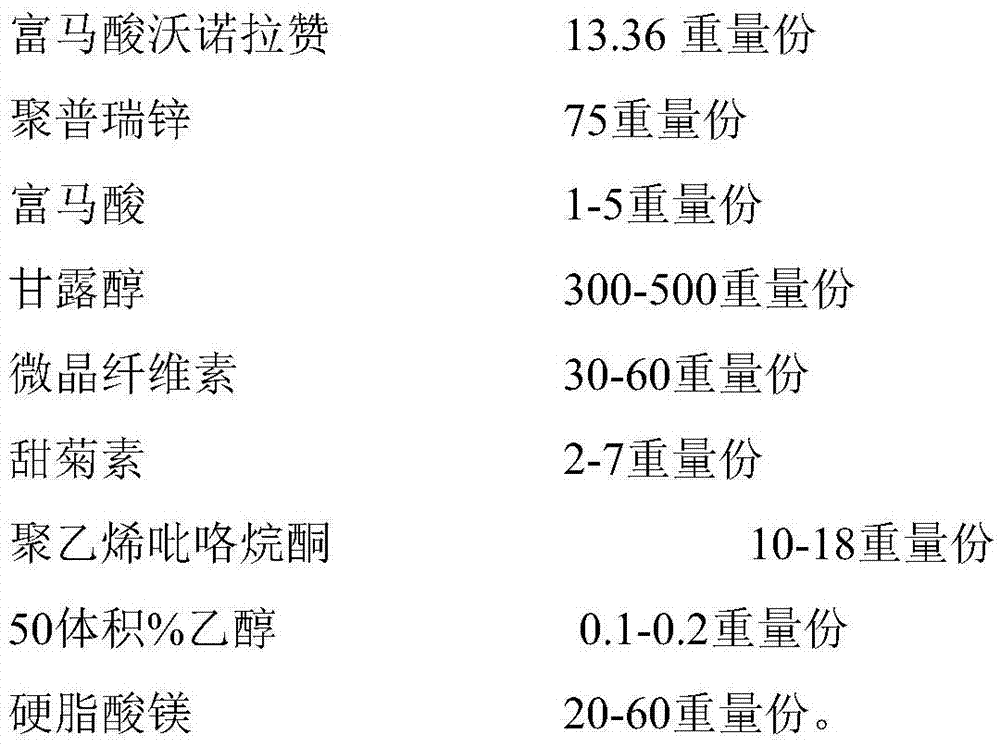

[0048]

[0049] Preparation method: Weigh the raw and auxiliary materials of the prescription amount, crush them, and sieve them for later use; mix fumaric acid and vonorazan fumarate evenly to obtain the mixture ①; mix the mixture ①, polyprezinc, Other auxiliary materials except magnesium fatty acid are put into the high-efficiency wet granulator and pre-mixed for 15 minutes; slowly add 50% ethanol solution to the high-efficiency wet granulator to make a soft material; The prepared soft material is granulated with a 24-mesh sieve; the prepared wet granules are put into a hot air circulation oven, and dried at 55-65°C until the moisture content is ≤1.0%; the dried granules are sieved with a 16-mesh and 80-mesh sieve respectively Sieve, collect the granules below 16 mesh sieve and above 80 mesh sieve; granulate the granules above 16 mesh sieve with 18 mesh sieve, collect the granules below 16 mesh sieve and above 80 mesh sieve; mix the granules with magnesium stearate 10min,...

Embodiment 2

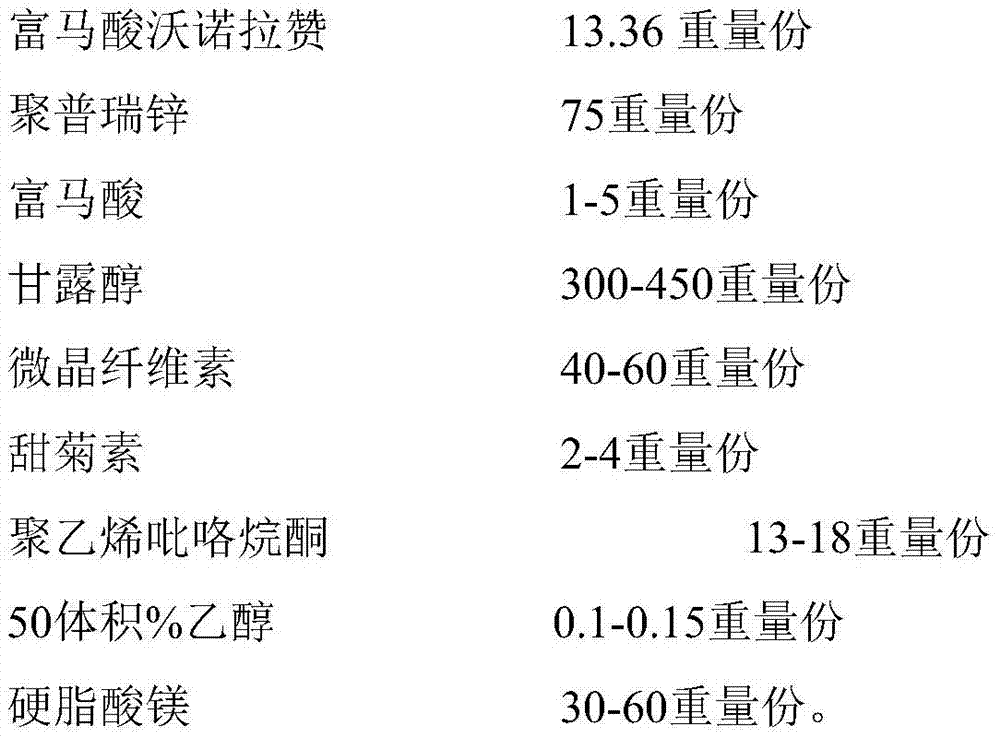

[0051]

[0052] Preparation method: Weigh the raw and auxiliary materials of the prescription amount, crush them, and sieve them for later use; mix fumaric acid and vonorazan fumarate evenly to obtain the mixture ①; mix the mixture ①, polyprezinc, Other auxiliary materials except magnesium fatty acid are put into the high-efficiency wet granulator and pre-mixed for 15 minutes; slowly add 50% ethanol solution to the high-efficiency wet granulator to make a soft material; The prepared soft material is granulated with a 24-mesh sieve; the prepared wet granules are put into a hot air circulation oven, and dried at 55-65°C until the moisture content is ≤1.0%; the dried granules are sieved with a 16-mesh and 80-mesh sieve respectively Sieve, collect the granules below 16 mesh sieve and above 80 mesh sieve; granulate the granules above 16 mesh sieve with 18 mesh sieve, collect the granules below 16 mesh sieve and above 80 mesh sieve; mix the granules with magnesium stearate 10min,...

Embodiment 3

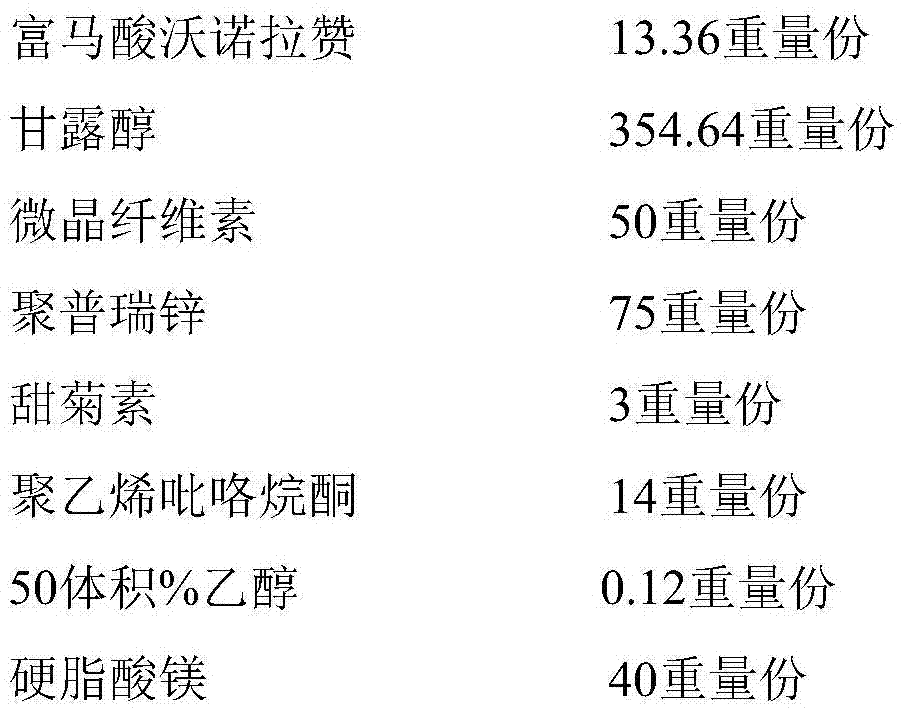

[0054]

[0055] Preparation method: Weigh the raw and auxiliary materials of the prescription amount, crush them, and sieve them for later use; mix fumaric acid and vonorazan fumarate evenly to obtain the mixture ①; mix the mixture ①, polyprezinc, Other auxiliary materials except magnesium fatty acid are put into the high-efficiency wet granulator and pre-mixed for 15 minutes; slowly add 50% ethanol solution to the high-efficiency wet granulator to make a soft material; The prepared soft material is granulated with a 24-mesh sieve; the prepared wet granules are put into a hot air circulation oven, and dried at 55-65°C until the moisture content is ≤1.0%; the dried granules are sieved with a 16-mesh and 80-mesh sieve respectively Sieve, collect the granules below 16 mesh sieve and above 80 mesh sieve; granulate the granules above 16 mesh sieve with 18 mesh sieve, collect the granules below 16 mesh sieve and above 80 mesh sieve; mix the granules with magnesium stearate 10min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com