Dried artificial bioprosthetic valve and preparation method thereof

A biological valve and artificial technology, applied in the field of medical devices, can solve problems such as inactivation, valve compression size cannot be further reduced, easy calcification, etc., to improve service life, good physical and chemical properties and biocompatibility, and simplify the use process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

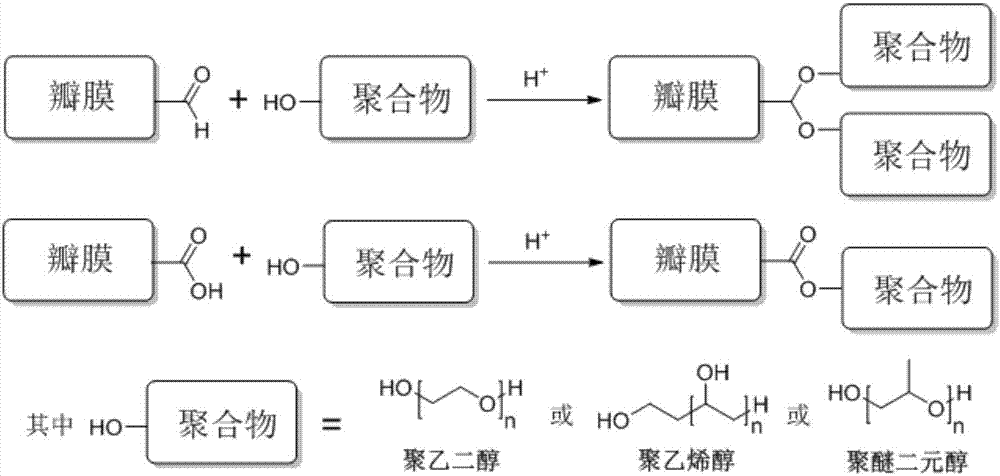

Method used

Image

Examples

Embodiment 1

[0047] Soak the porcine pericardial valve in a 5% glutaraldehyde solution for 2 days, take it out and wash it, and obtain a cross-linked and fixed artificial biological valve; then place the cross-linked and fixed artificial biological valve at a temperature of 45° C. 5.5. Soak in 20% polyethylene glycol and polyvinyl alcohol mixed solution for 7 days, take it out, and finally dry it completely at 20°C to obtain a dry artificial biological valve.

[0048] It was found through testing that the dry artificial biovalve prepared in this embodiment has excellent flexibility, and the dimension of the valve after compression is reduced by 80%, and has good biocompatibility and stable properties.

Embodiment 2

[0050] Soak the porcine pericardial valve in 4% glutaraldehyde solution for 3 days, take it out and wash it, and obtain a cross-linked and fixed artificial biological valve; then place the cross-linked and fixed artificial biological valve at a temperature of 40°C, and the pH 4.5. Soak in 30% polyethylene glycol and polyvinyl alcohol mixed solution for 5 days, take it out, and finally dry it completely at 25°C to obtain a dry artificial biological valve.

[0051] It was found through testing that the dry artificial biovalve prepared in this embodiment has excellent flexibility, and the dimension of the valve after compression is reduced by 80%, and has good biocompatibility and stable properties.

Embodiment 3

[0053] Soak the porcine pericardial valve in a 3% glutaraldehyde solution for 4 days, take it out and wash it, and obtain a cross-linked and fixed artificial biological valve; then place the cross-linked and fixed artificial biological valve at a temperature of 35° C. 4.0. Soak it in 40% polyethylene glycol solution for 3 days, take it out, and finally dry it completely at 30° C. to obtain a dry artificial biological valve.

[0054] It was found through testing that the dry artificial biovalve prepared in this embodiment has excellent flexibility, and the dimension of the valve after compression is reduced by 80%, and has good biocompatibility and stable properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com