Reaction vessel capable of realizing rapid temperature increase in virtue of inner heating coil assisted by electrothermal outer jacket

An outer jacket and reaction kettle technology, applied in the field of reaction kettles, can solve problems such as inability to meet requirements, and achieve the effects of saving energy, increasing internal temperature, and increasing temperature quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

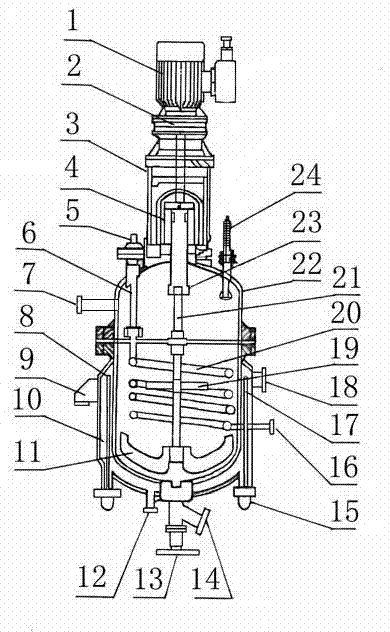

[0011] attached by figure 1 As shown, an electrothermal outer jacket assisted internal heating coil rapid heating reaction kettle consists of a motor 1, a reducer 2, a bracket 3, a sealing sleeve 4, a heat inlet pipe control valve 5, an internal heat medium circulation inlet pipe 6, and a feed pipe 7 , electromagnetic heating tube a8, kettle ear 9, heating outer interlayer 10, arcuate stirring fin 11, outer interlayer heat transfer medium discharge pipe 12, discharge control valve 13, discharge pipe 14, heating pipe power supply connection box 15, internal heat medium circulation Outlet pipe 16, electromagnetic heating pipe b17, outer interlayer heat transfer medium adding pipe 18, middle stirring fin 19, inner heating coil 20, stirring shaft 21, kettle body 22, connecting sleeve 23, safety valve 24; the upper center of kettle body 22 Set up a bracket 3, the upper part of the bracket 3 is equipped with a reducer 2 with a motor 1, one side of the upper part of the kettle body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com