A hydraulic end assembly of a plunger pump with a conical surface positioning sealing box body

A liquid end, plunger pump technology, applied to the components of the pumping device for elastic fluid, pump components, variable displacement pump components, etc., to reduce accumulation errors, reduce stress concentration points, and reduce accumulation effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

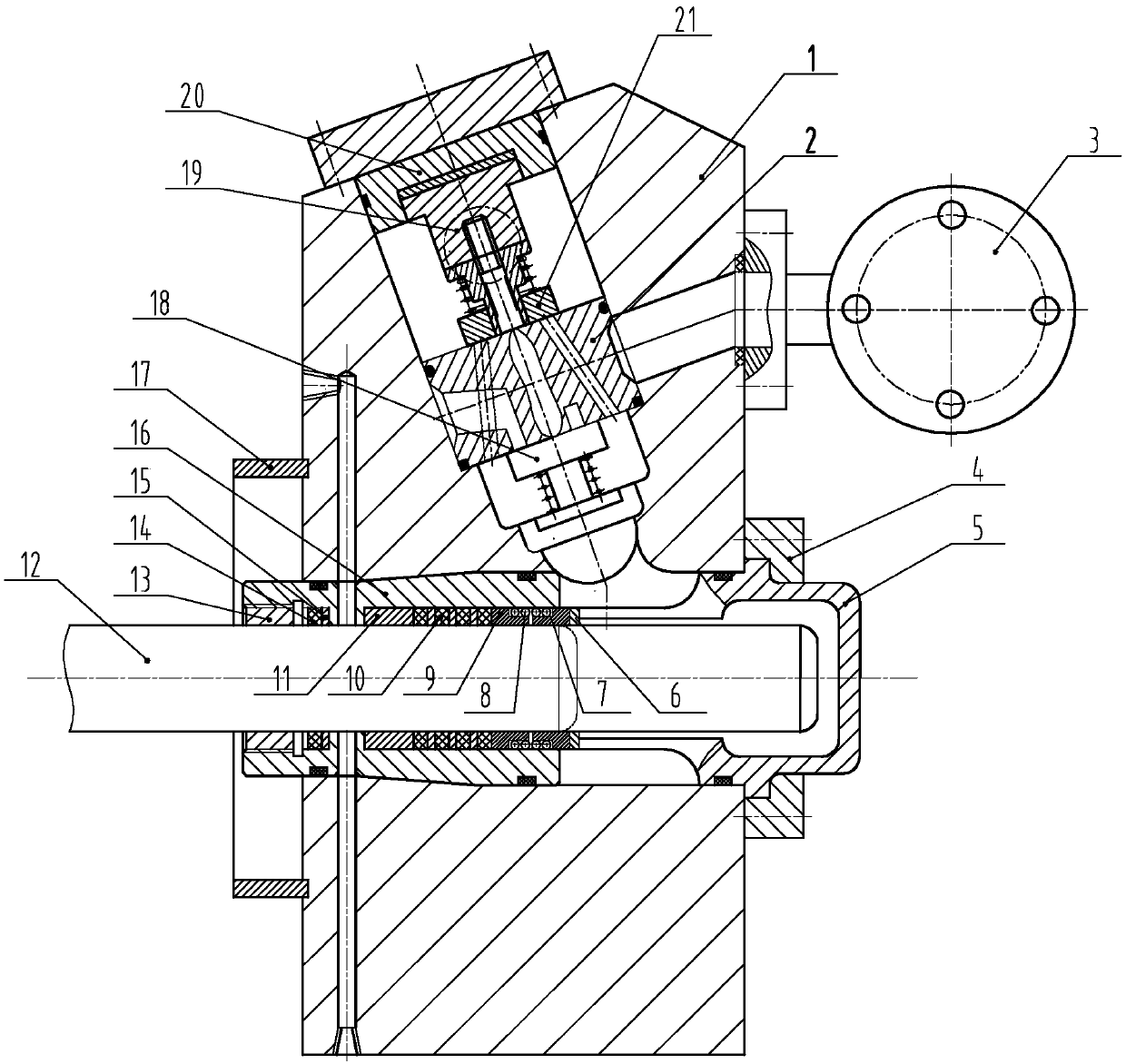

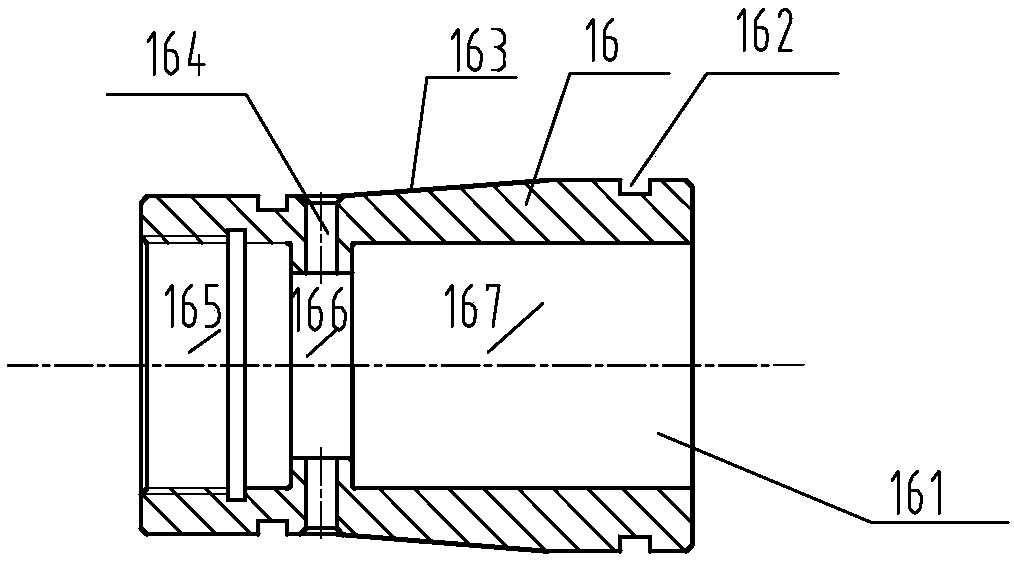

[0029] Please refer to Figure 1-Figure 3 As shown, the hydraulic end assembly of the conical surface positioning sealing body of the present invention mainly includes a pump body 1, a plunger 12, a sealing body 16, a combined valve 2, a packing assembly, an auxiliary packing 14, a water ring sleeve 5, Positioning sleeve 17 and water collector 3 etc., wherein:

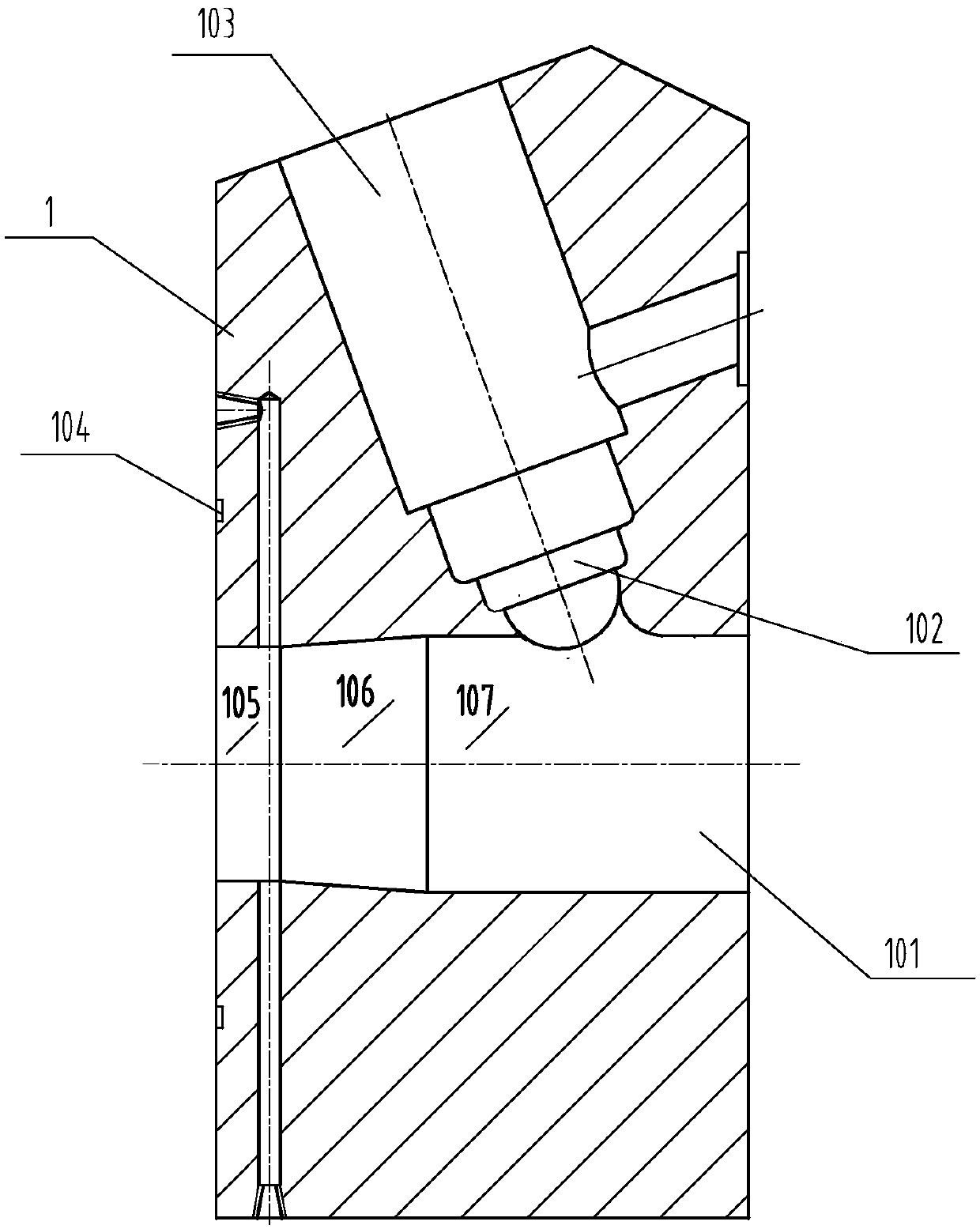

[0030] The cavity structure of the pump body 1 is as follows: figure 2 As shown, a plunger passage 101 and a combination valve passage 103 communicated with the plunger passage are provided inside. In this embodiment, the two passages have a V-shaped structure in which the center line forms a non-90-degree angle, so that the valves located in the combination valve passage Combination valve is oblique vertical linear movement. Of course, the arrangement of the two channels is not li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com