A device and method for measuring the flow rate of a pressure main pipe of a hydropower station

A technology for pressure main pipe and flow measurement, which is applied in the direction of measuring device, measuring capacity, liquid/fluid solid measurement, etc. It can solve the problems such as no method for determining the diameter of the bypass pipe, no description of the measurement method, and low pressure head. Achieve market application prospects and considerable social benefits, solve the effects of low flow measurement accuracy and reduced straight pipe length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

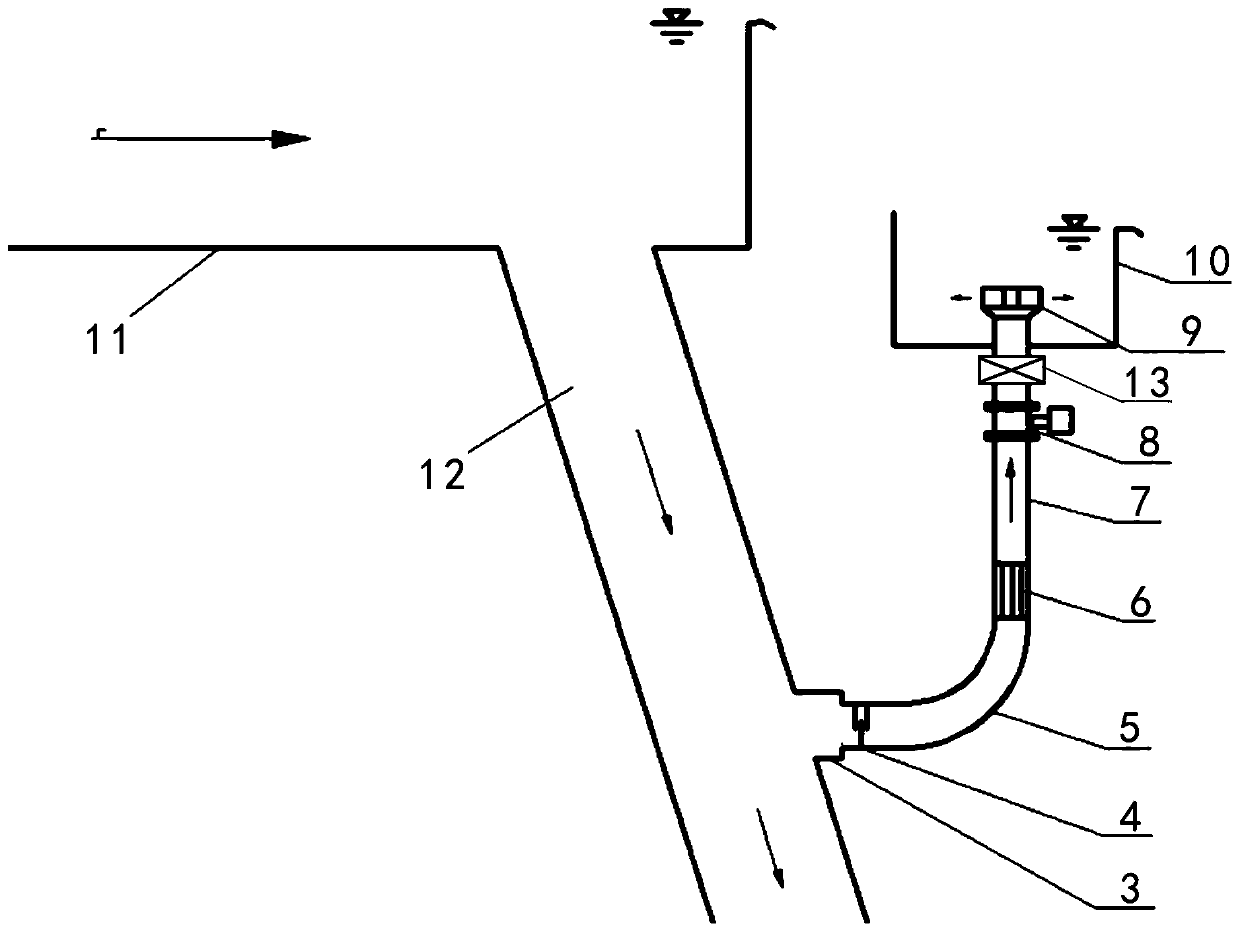

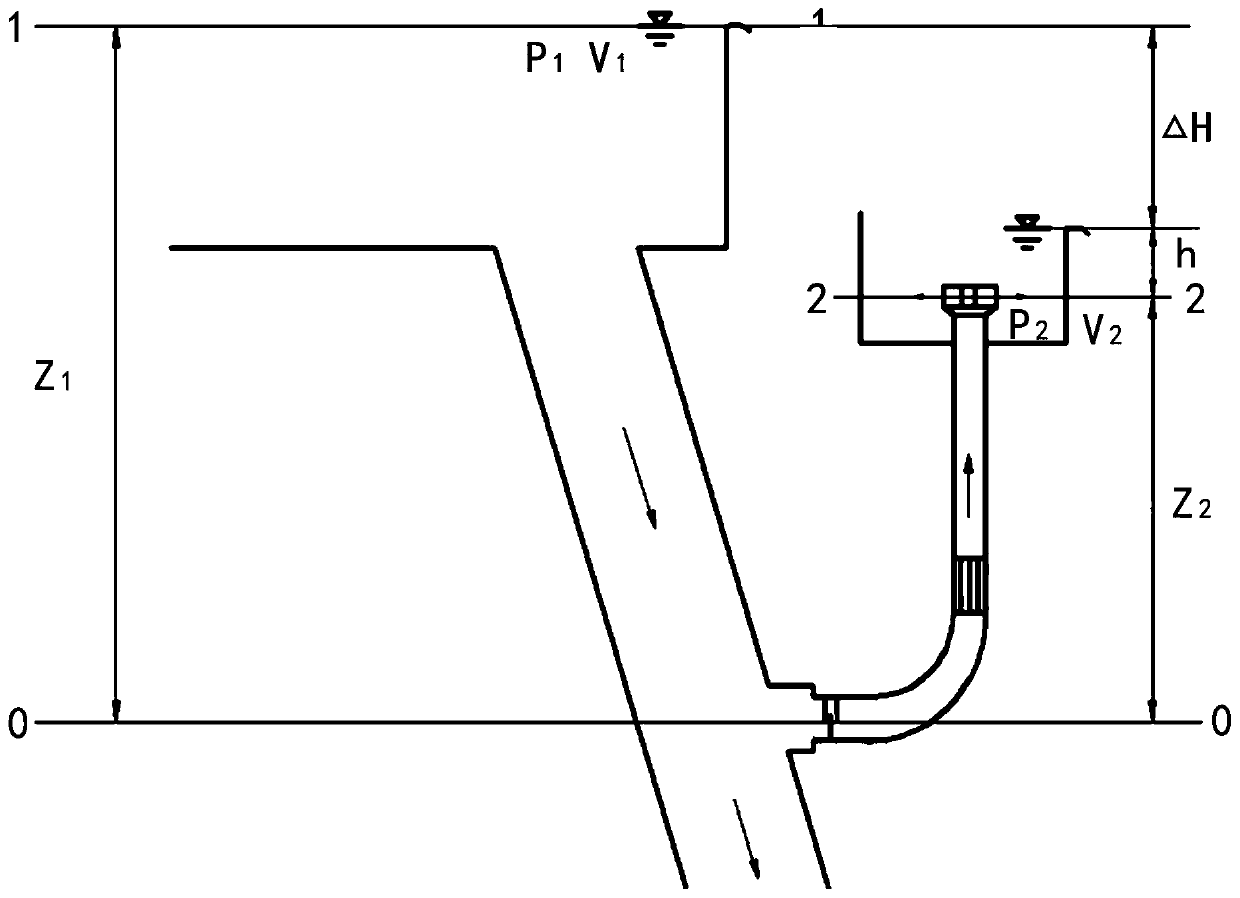

[0024] Such as figure 1 As shown, the device for flow measurement of the pressure main pipe of a hydropower station according to the present invention includes a forebay 11, a pressure main pipe 12, a tee pipe 3, a bypass pipe, a throttle valve 4, a rectifying beam 6, a vortex flowmeter 8, and a valve 13. The overflow window 9 and the overflow tank 10, the pressure main pipe 12 communicates with the forebay 11, and the bypass pipe includes an elbow 5 and a straight pipe 7 connected to each other, and the elbow 5 is connected to the pressure main pipe through the tee pipe 3 12 connected, one end of the throttle valve 4 is connected to the pressure main pipe 12, the other end of the throttle valve 4 is connected to one end of the elbow 5, and the vortex flowmeter 8 used to measure the water flow in the straight pipe 7 is installed in the straight pipe 7, the rectifier bundle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com