Continuous steaming machine

A cooking machine and rack technology, applied in food science and other directions, can solve problems such as inability to meet large-scale processing and production, inability to operate continuously and uninterrupted, and difficult to control the cooking process, and achieve convenient delivery, reasonable structure design, and suitable temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

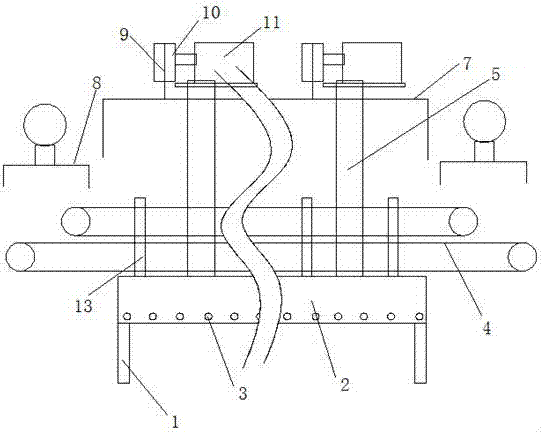

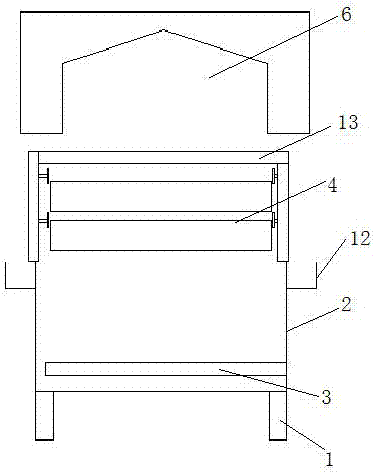

[0024] See attached picture.

[0025] A continuous cooking machine, comprising a frame 1, a water tank 2 is mounted on the frame 1, a steam heating pipe 3 is laid in the water tank 2, a circulating conveying chain plate 4 is mounted on the frame above the water tank 2, and the circulating conveying chain plate Ventilation holes are distributed on the 4, and a steam cover 7 is erected above the circulating conveying chain plate 4, and the steam cover 7 is driven by a lifting mechanism above it.

[0026] The circular conveying chain plate 4 includes a multi-layer circular conveying chain plate arranged at intervals, and the upper layer and the lower layer at the end of the feeding end are misplaced, and the upper layer is shorter than the lower layer.

[0027] Described circulation conveying chain plate 4 has two layers.

[0028] The steam cover can move up and down, and its lifting is driven by a lifting mechanism.

[0029] The lifting mechanism includes a steel wire rope 9 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com