Dielectrophoresis electrode structure for emitting non-homogeneous electric field outwards

A technology of dielectrophoresis and electrode structure, applied in the direction of electrode, electrodialysis, electrolysis process, etc., can solve the problems of high cost, membrane pollution, short concentration cycle, etc., and achieve the effect of increasing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

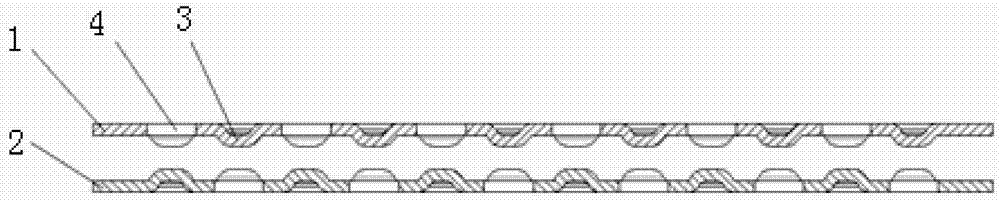

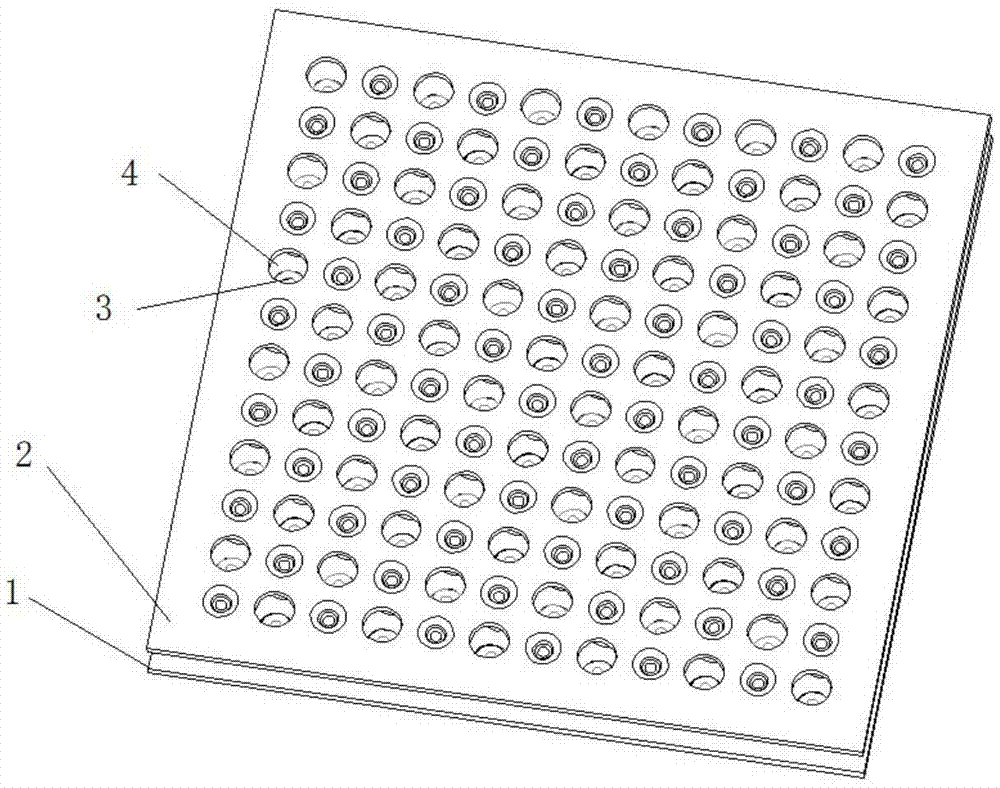

[0036] Such as figure 1 , figure 2 As shown, the dielectrophoretic electrode structure of the present invention includes a first electrode plate 1 and a second electrode plate 2, both of which are sheet-like structures, on which columnar protrusions 3 and holes are all arranged. Position 4, the shape and size of the columnar protrusion 3 on one electrode plate matches the shape and size of the hole 4 on the other electrode plate, and the height of the columnar protrusion 3 is consistent with the thickness of the electrode plate. The outer surfaces of the first electrode plate 1 and the second electrode plate 2 have an insulating layer, and the positions of the columnar protrusions 3 of the first electrode plate 1 and the holes 4 of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com