Spreading and seed selecting vehicle for grain sunning ground

A technology for grains and drying fields, which is applied in the treatment of seeds and rhizomes, preservation of seeds by drying, separation of solids, etc., can solve the problems of large workload, grain screening, low efficiency, etc., to improve labor efficiency, reduce labor level, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

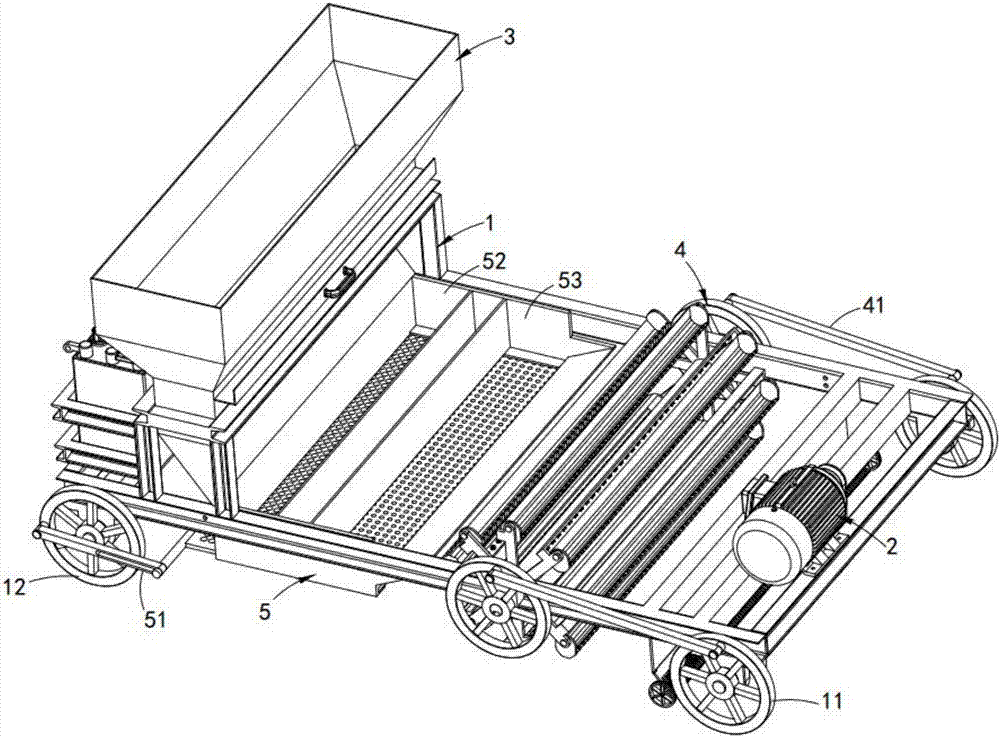

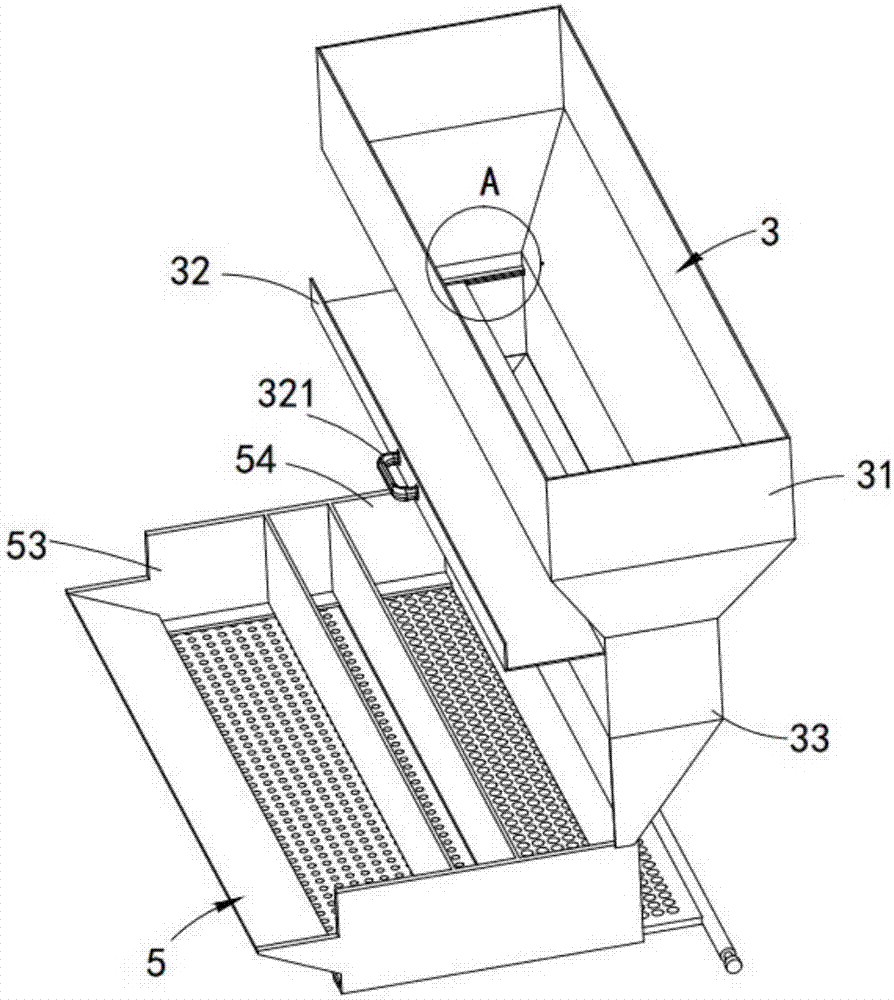

[0062] Such as figure 1 As shown, a grain drying field flattening seed selection vehicle includes a frame 1, a driving mechanism 2, a discharge mechanism 3, a material taking mechanism 4 and a flattening seed selection mechanism 5, and the front and rear ends of the frame 1 are symmetrical A driving roller 11 and a driven roller 12 are provided, and the driving roller 11 is located on the rear side of the driven roller 12;

[0063] The driving mechanism 2 is fixedly arranged on the frame 1, and is connected with the driving roller 11 through a belt transmission mode, and drives the driving roller 11 to rotate;

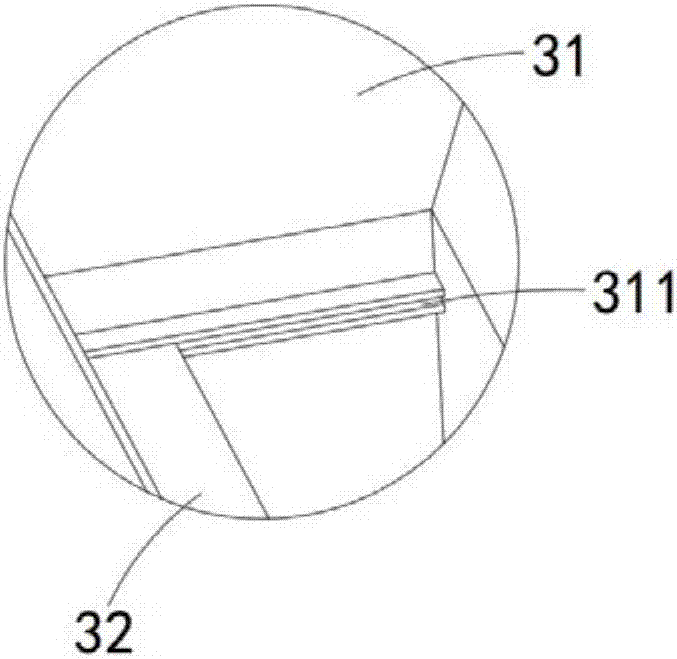

[0064] The discharge mechanism 3 is fixedly arranged on the front end of the frame 1, and the flat seed selection mechanism 5 is arranged below it, and the discharge mechanism 3 is used to store grain, and output the grain to the flatten. Inside the seed selection institution 5;

[0065] The two ends of the retrieving mechanism 4 are rotatably arranged on the frame 1...

Embodiment 2

[0095] Figure 11 It is a kind of structure schematic diagram of the embodiment 2 of flattening seed selection car in a kind of grain drying field of the present invention; Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0096] Such as Figure 11 As shown, a grain drying field flattening seed selection vehicle also includes a ditching mechanism 6 arranged between the reclaiming mechanism 4 and the driving roller 11, and the ditching mechanism 6 includes a connecting plate 61 and a ditching assembly 62 , the upper end of the connecting plate 61 is fixedly connected with the frame 1 , and the lower end thereof is hinged with the trench assembly 62 , and the trenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com