Medical dental pad base film and preparation method thereof

A basement film and dental technology, applied in the field of medical dental pad basement film and its preparation, can solve problems such as adhesive failure and delamination, achieve the effects of reducing temperature difference, improving production quality, and improving composite quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

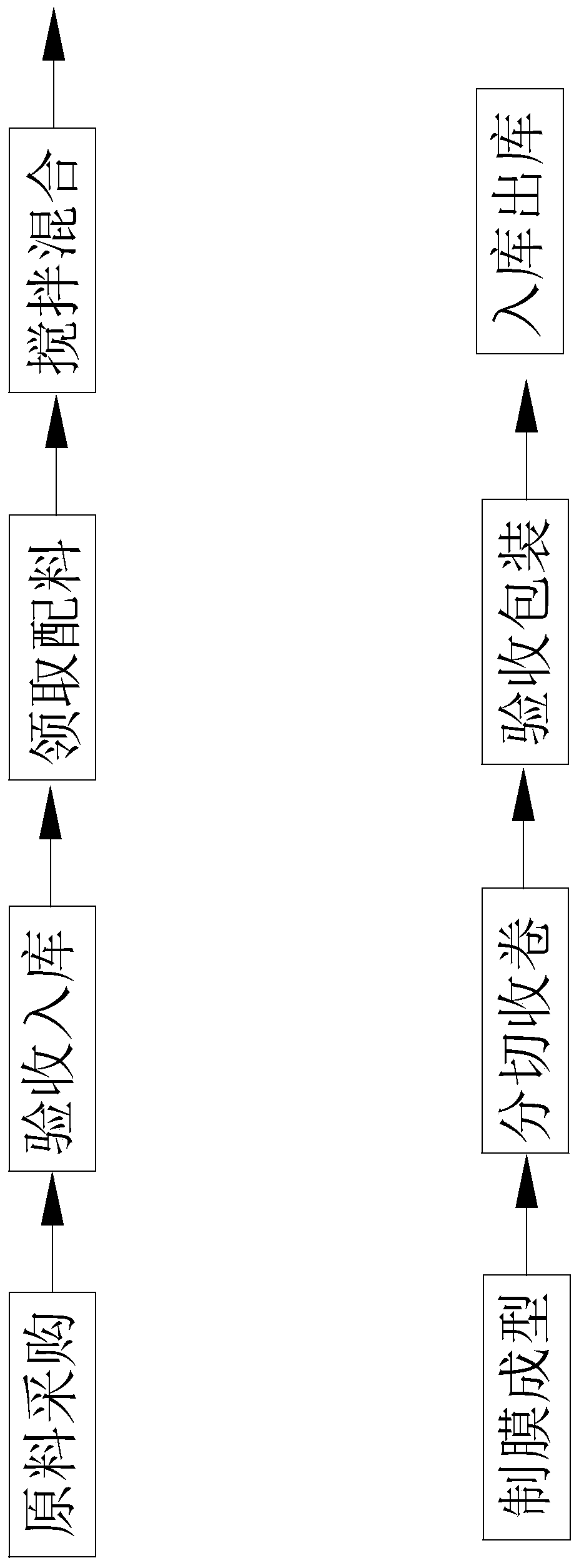

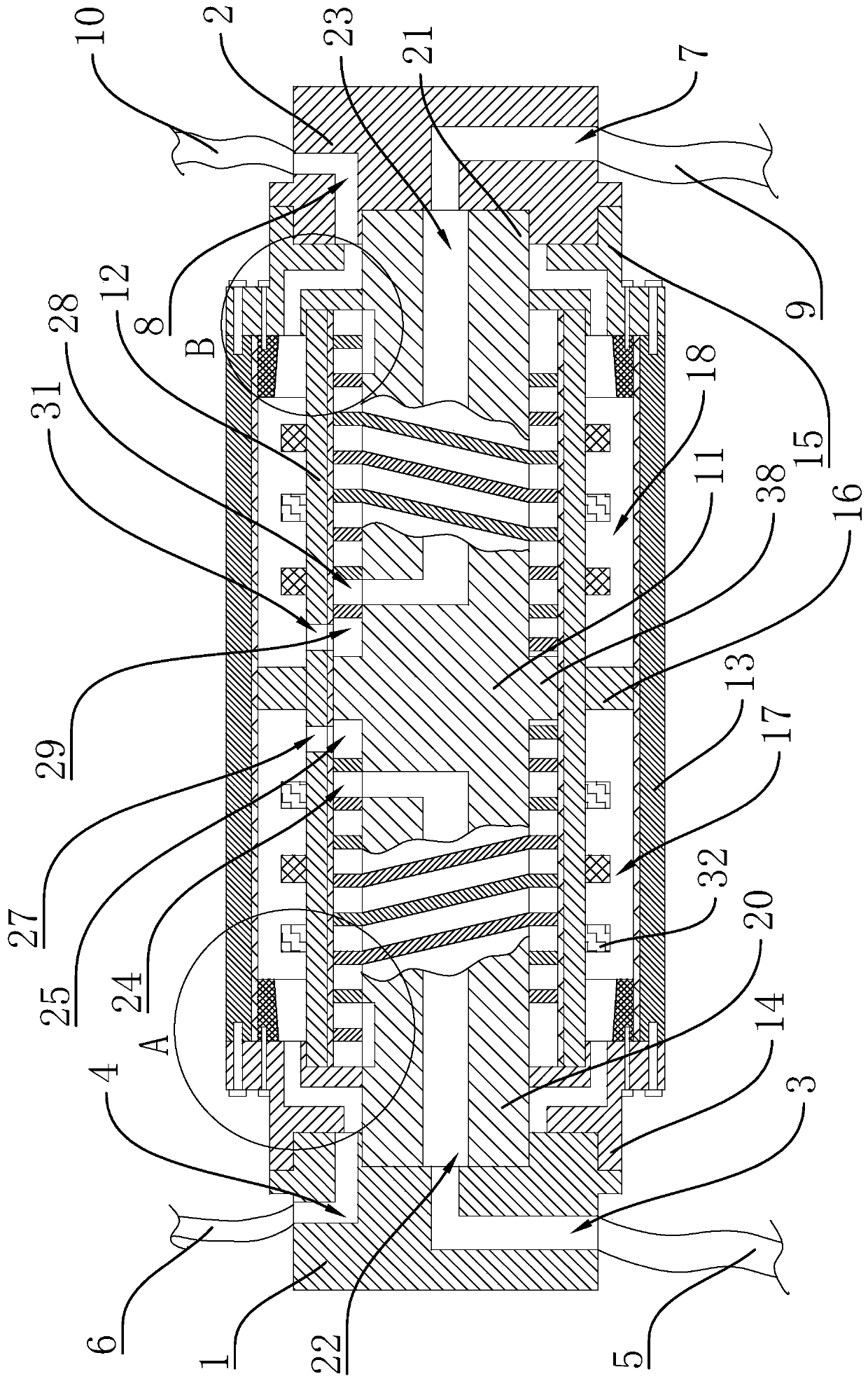

Method used

Image

Examples

Embodiment 1

[0035] Medical dental pad base film, each component and its content percentage in this base film are:

[0036]

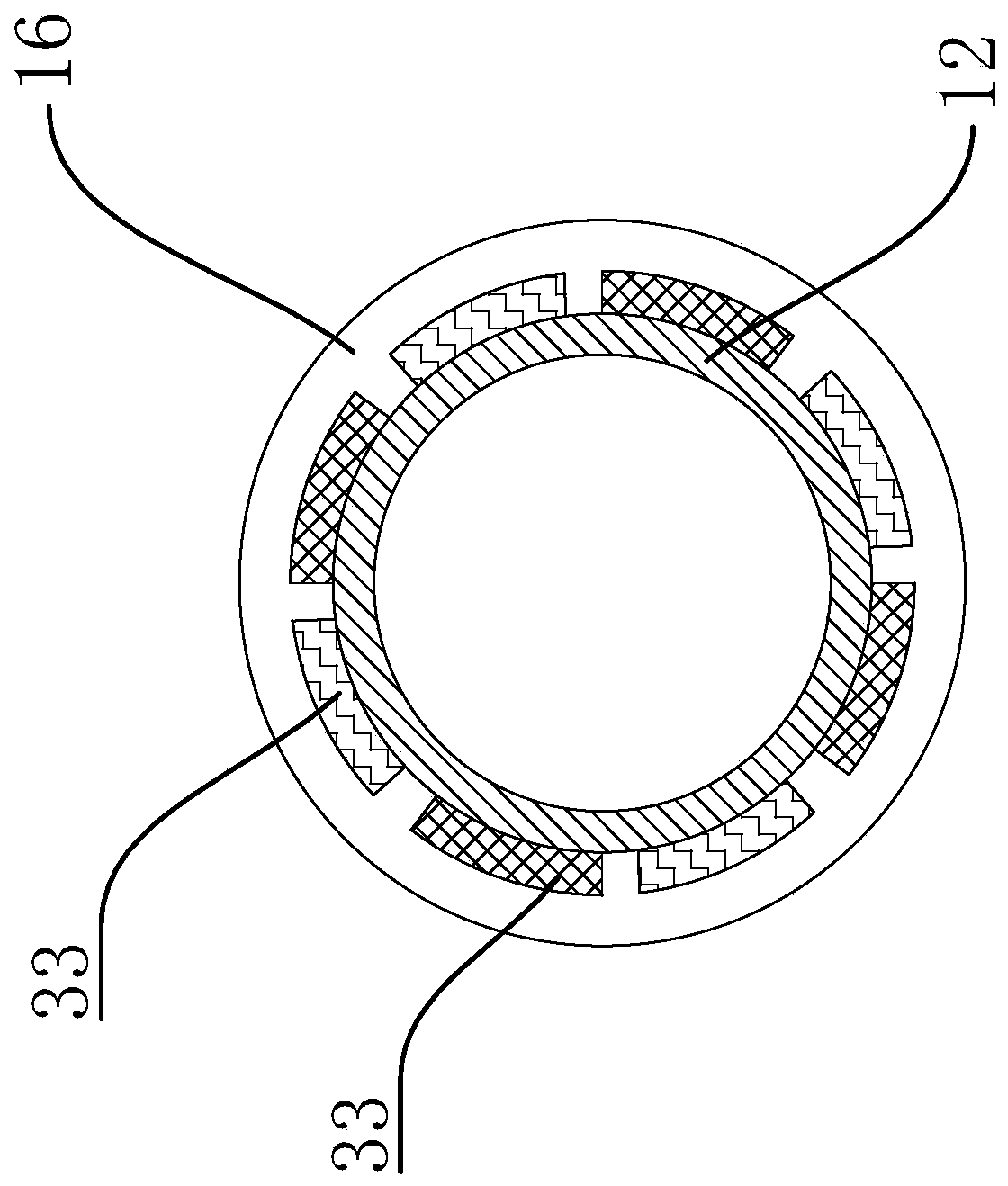

[0037] The surface of the base film is formed with concavo-convex lines by embossing rollers, so that the surface of the base film has a matte effect.

Embodiment 2

[0039] Medical dental pad base film, each component and its content percentage in this base film are:

[0040]

[0041]The surface of the base film is formed with concavo-convex lines by embossing rollers, so that the surface of the base film has a matte effect.

Embodiment 3

[0043] Medical dental pad base film, each component and its content percentage in this base film are:

[0044]

[0045]

[0046] The surface of the base film is formed with concavo-convex lines by embossing rollers, so that the surface of the base film has a matte effect.

[0047] When the dental pad is finally used, it is necessary to use glue on both sides of the base film to fit the toilet paper. Using glue is easy to damage the toilet paper. Therefore, we add thermal adhesive to the base film, let the finished product factory remove the glue compound machine, and directly use heat compression molding Machine, one-step production, fast and convenient. The adhesive effect produced by the two additives in the base film of the present invention after high temperature is just enough for the composite fastness of toilet paper, thereby solving the problem that the finished product is easy to delaminate during use, not only improving the composite quality of the finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com