Composition used for pure electric vehicle transmission oil and preparation method thereof as well as transmission oil containing composition and preparation method thereof

A pure electric vehicle and transmission oil technology, which is applied in the field of lubricating oil, can solve the problems of pure electric vehicle installation design and matching difficulty, large volume and weight of the transmission, and strict lubrication of the transmission, so as to achieve good material adaptation Performance, good extreme pressure and anti-wear performance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

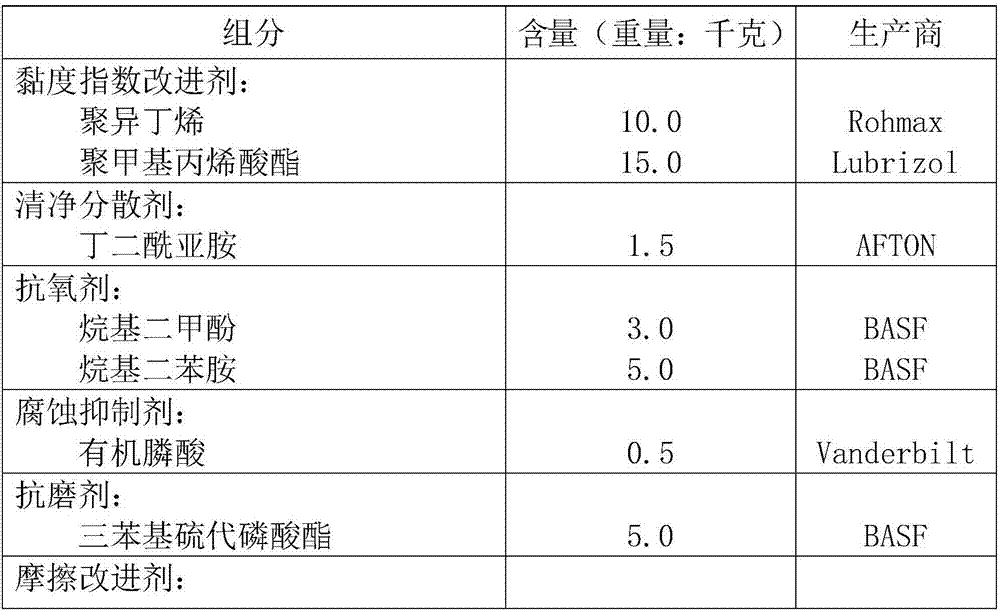

[0041] The composition of this composition that is used for pure electric vehicle transmission oil is as follows (in 100 kilograms, hereinafter the same):

[0042]

[0043]The preparation method of the composition that is used for pure electric vehicle transmission oil, adopts the following steps:

[0044] (1-1) Add 30% of the weight of Type III hydrogenated base oil into the blending tank, then add all the PAO synthetic base oil, stir and mix, and heat to 45°C under normal pressure; on the premise of satisfying the amount of dissolved additives In this case, adding a small amount of base oil can save heating time and improve production efficiency;

[0045] (1-2) Add a friction modifier to the base oil A obtained by heating in step (1-1) while stirring, and stir and mix at 45° C. for 35 minutes under normal pressure;

[0046] (1-3) Add a viscosity index improver to the mixture obtained in step (1-2) while stirring, heat up to 85° C. under normal pressure, stir and mix for ...

Embodiment 12

[0050] The composition of this composition that is used for pure electric vehicle transmission oil is as follows (in 100 kilograms, hereinafter the same):

[0051]

[0052]

[0053] The preparation method of the composition that is used for pure electric vehicle transmission oil, adopts the following steps:

[0054] (1-1) Add 30% of the weight of Type III hydrogenated base oil into the blending tank, then add all the PAO synthetic base oil, stir and mix, and heat to 35°C under normal pressure; on the premise of satisfying the amount of dissolved additives In this case, adding a small amount of base oil can save heating time and improve production efficiency;

[0055] (1-2) Add a friction modifier to the base oil A obtained by heating in step (1-1) while stirring, and stir and mix at 35° C. for 25 minutes under normal pressure;

[0056] (1-3) Add a viscosity index improver to the mixture obtained in step (1-2) while stirring, heat up to 75° C. under normal pressure, stir...

Embodiment 13

[0060] The composition of this composition that is used for pure electric vehicle transmission oil is as follows (in 100 kilograms, hereinafter the same):

[0061]

[0062]

[0063] The preparation method of the composition that is used for pure electric vehicle transmission oil, adopts the following steps:

[0064] (1-1) Add 30% of the weight of Type III hydrogenated base oil into the blending tank, then add all the ester synthetic base oil, stir and mix, and heat to 40°C under normal pressure; on the premise of satisfying the amount of dissolved additives In this case, adding a small amount of base oil can save heating time and improve production efficiency;

[0065] (1-2) Add a friction modifier to the base oil A obtained by heating in step (1-1) while stirring, and stir and mix at 40° C. for 30 minutes under normal pressure;

[0066] (1-3) Add a viscosity index improver to the mixture obtained in step (1-2) while stirring, heat up to 80°C under normal pressure, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com