Beam connection structure of assembly type concrete frame

A concrete and prefabricated technology, applied in building structures, buildings, etc., can solve the problems of easily damaged rigid connection structures, complex connection structures, irreplaceable connection structures, etc., to achieve excellent structural performance, reduce structural repair difficulties, Avoid the effects of structural reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

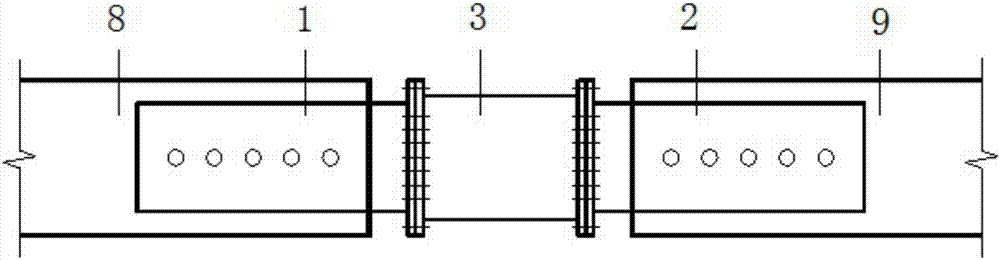

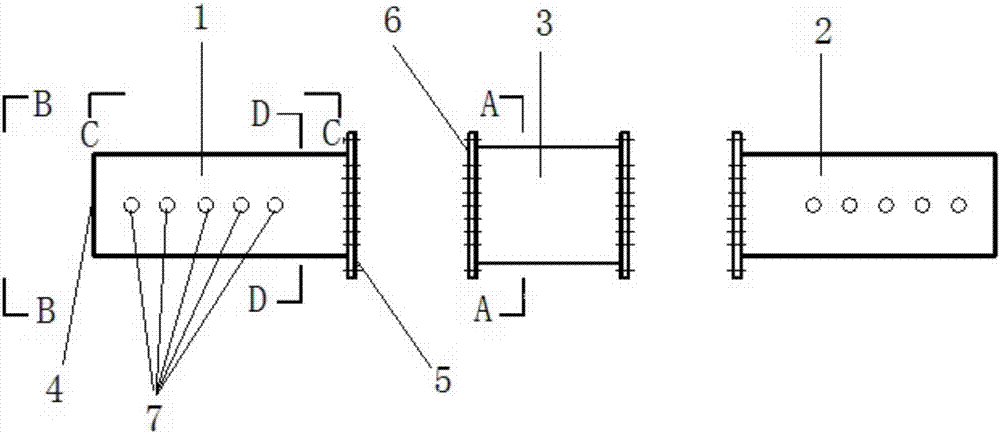

[0022] The structure of the connection structure of a prefabricated concrete frame beam of the present invention is as follows figure 1 and figure 2 As shown, including the left embedded section 1, the connecting section 3, and the right embedded section 2 (such as figure 1 As shown), there are 4 connecting end plates between the embedded section and the connecting section (one first connecting end plate 5 at the right end of the left embedded section, one first connecting end plate 5 at the left end of the right embedded section, and the left and right connecting section 2 second connecting end plates 6) at both ends, and some end plate connecting bolts. Among them, the left embedded section 1, the connecting section 3, and the right embedded section 2 are all box-section steel members. Both the left pre-embedded section 1 and the right pre-embedded sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com