Vibration power generating device and wind power generator with same

A technology of wind power generator and vibration power generation, which is applied to wind power generators, mechanisms for generating mechanical power, engines, etc. It can solve problems such as different structures, damage to wind power generator components, and loose connection parts, so as to increase power generation and absorb Vibration energy, vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

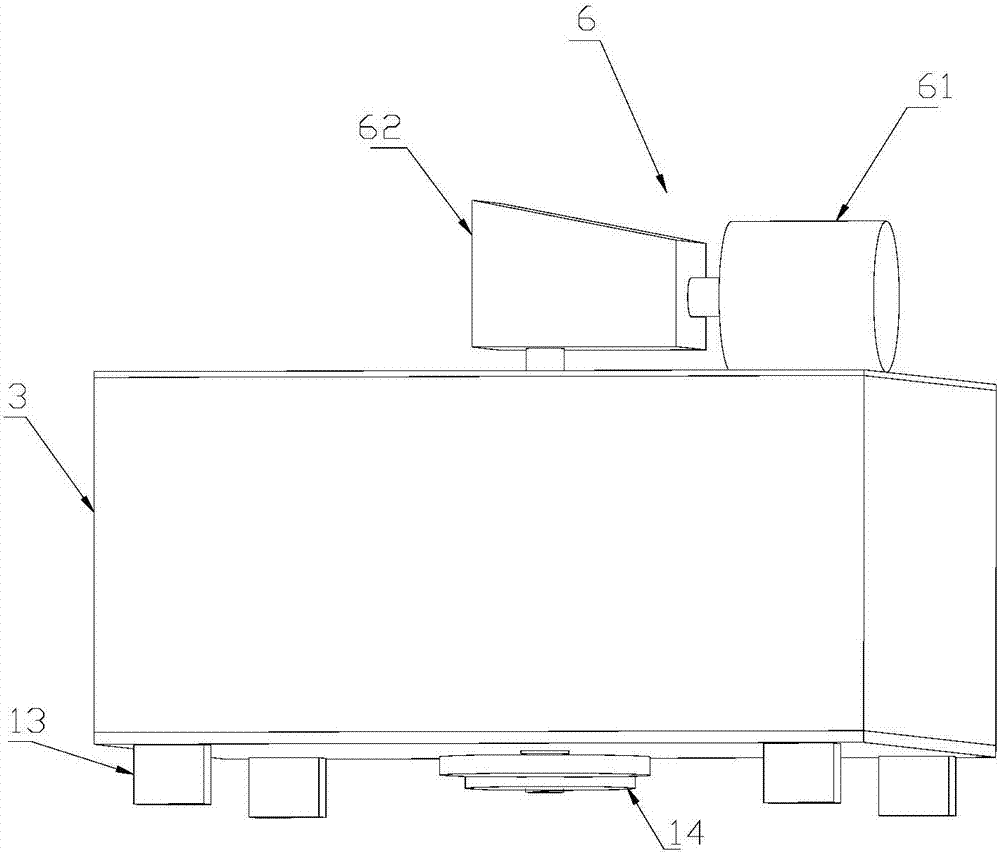

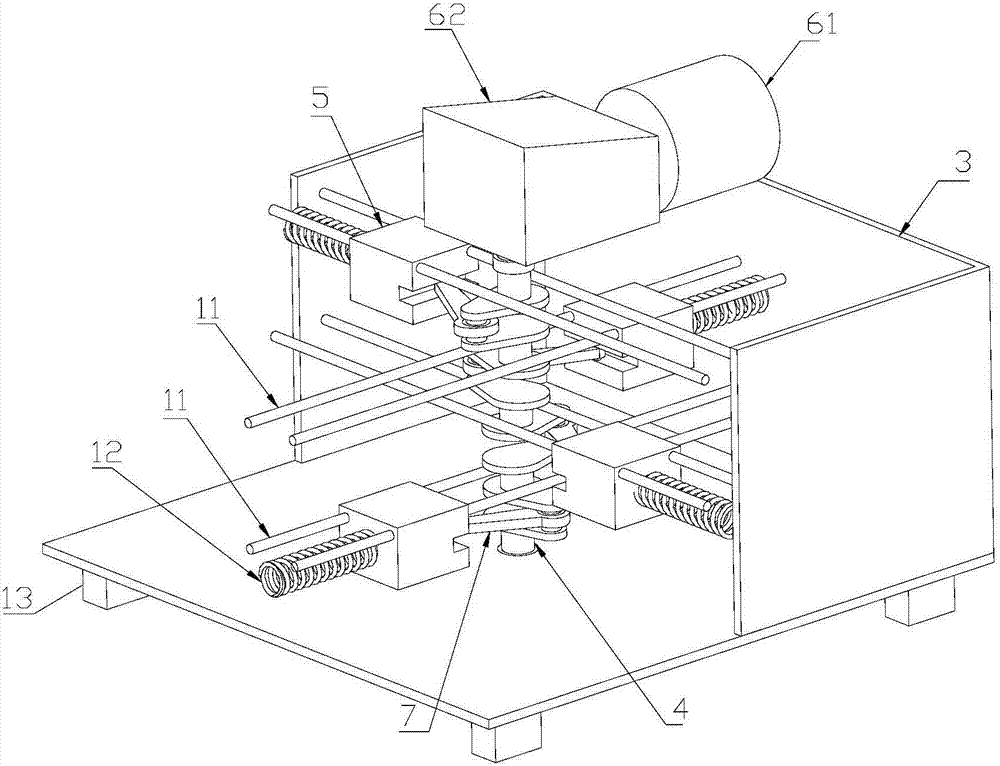

[0035] Such as figure 1 and figure 2 As shown, a vibration power generation device includes a box-shaped housing 3, an inertial element 5 movably arranged in the housing 3, a buffer device 12 connecting the inertial element 5 and the housing 3, and the two ends are opposite to each other. The housing 3 is rotatably connected to the crankshaft 4 connected to the inertial element 5 through the connecting rod 7, and the generator 6 is connected to one end of the crankshaft 4 and driven by the crankshaft 4 to generate electricity.

[0036] The housing 3 is fixedly mounted on the vibration source and vibrates synchronously with the vibration source. The inertial element 5 can freely reciprocate relative to the housing 3 in a horizontal direction. When the housing 3 vibrates with the vibration source, the inertia Due to the action of inertia, the element 5 has a motion tendency to keep still. The vibrating shell 3 and the inertial element 5 that remains stationary will move relati...

Embodiment 2

[0049] Such as Figure 5 And me Figure 6 As shown, the number of inertial elements 5 in this embodiment is two, and they are arranged at different heights along the axial direction of the crankshaft 4. The two inertial elements 5 are respectively located on both sides of the crankshaft 4, and the phase difference between the two is π / 2 radians, when one of the inertial elements 5 is in the dead point of motion, the other inertial element 5 has just passed the dead point, and pushes the crankshaft 4 to rotate in one direction under the action of inertial force, which can be effectively overcome by setting two inertial elements 5 A single inertial element 5 has the problem of motion dead point. This embodiment has a simple structure and is mainly applied to a vibration source with a single vibration direction.

Embodiment 3

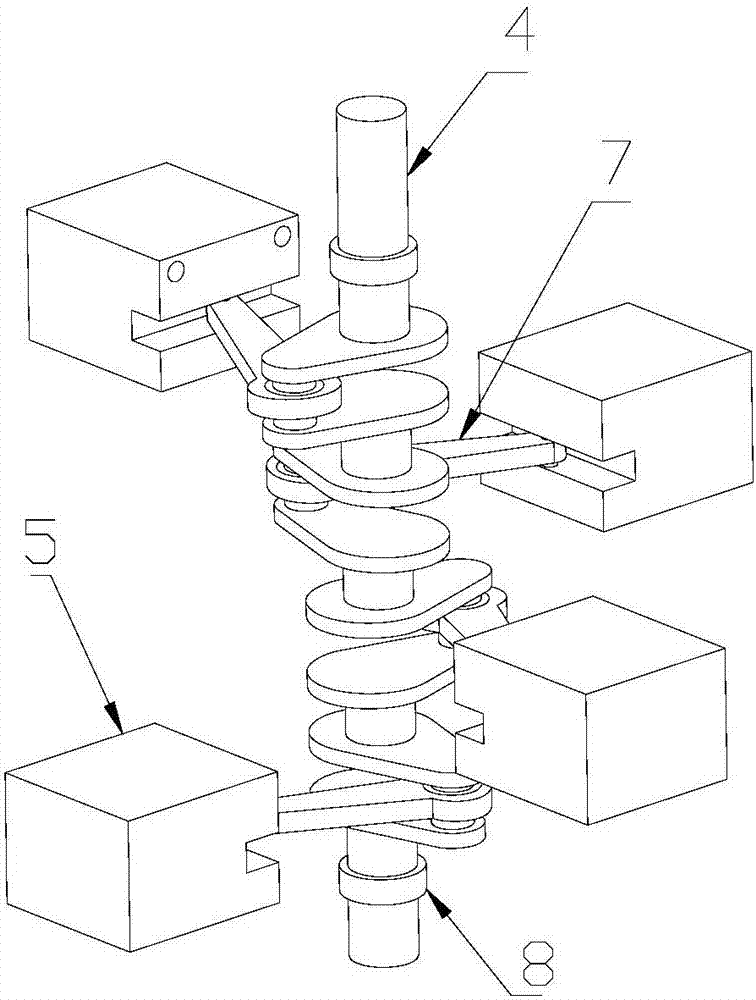

[0051] Such as Figure 7 and Figure 8 As shown, in order to enable the vibration power generation device of the present invention to absorb vibration energy in multiple directions, the number of inertial elements 5 in this embodiment is four, and they are distributed on four front, rear, left and right sides of the crankshaft 4 accordingly. side, both ends of the crankshaft 4 are connected to the housing 3 through bearings 8, and one end extends to the outside of the housing 3 to connect with the power generation device 6; The axis is rotated at an angle of 90 degrees, and arranged in the order of left, right, rear, and front, that is, this embodiment adds a pair of inertial elements 5 on the basis of the second embodiment, and through a different arrangement from the first embodiment In this way, the starting torque can be reduced to achieve better power generation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com