Heavy water reactor fuel element bending gauge calibration gauge and field calibration method

A technology of fuel elements and calibration gauges, which is applied in the direction of mechanical counter/curvature measurement, mechanical diameter measurement, etc., can solve the problems of difficult measurement, long calibration time and circulation time, wrong acceptance of measuring tools as qualified, etc., to improve calibration efficiency, The effect of shortening the calibration cycle and saving calibration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

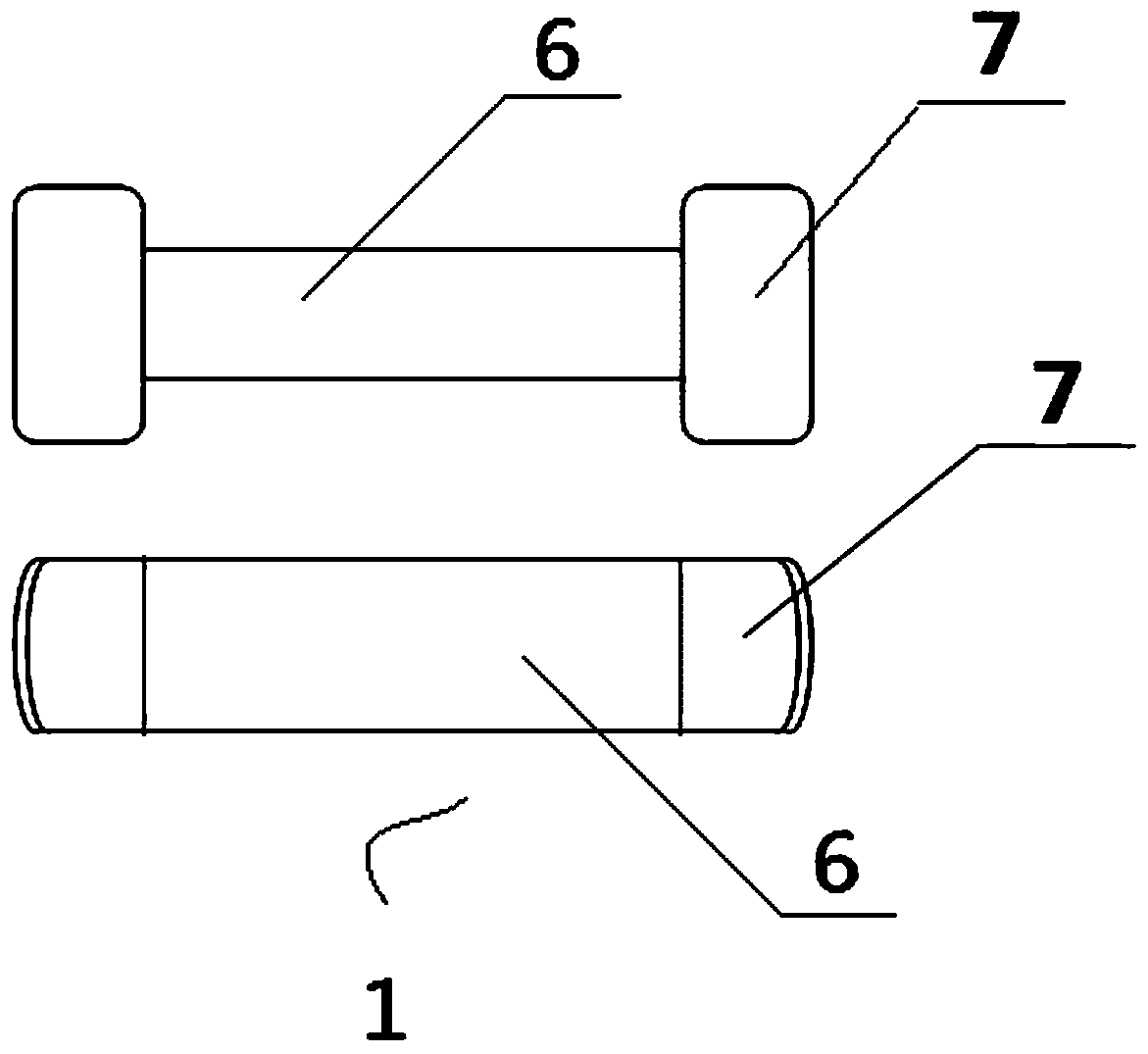

[0037] The on-site calibration gauge for bending pipe gauges of heavy water reactor fuel elements of the present invention includes a diameter calibration gauge 1 and a curvature calibration gauge 5 . The structure of the diameter calibration gauge is as attached figure 1 As shown, it includes a square rod 6 and a cuboid 7 located at both ends of the square rod 6. The outer sides of the two cuboids 7 are cylindrical, that is, the outer sides of their sections are arcs. The arc diameter Φ 1 The value range is 100mm to 103mm.

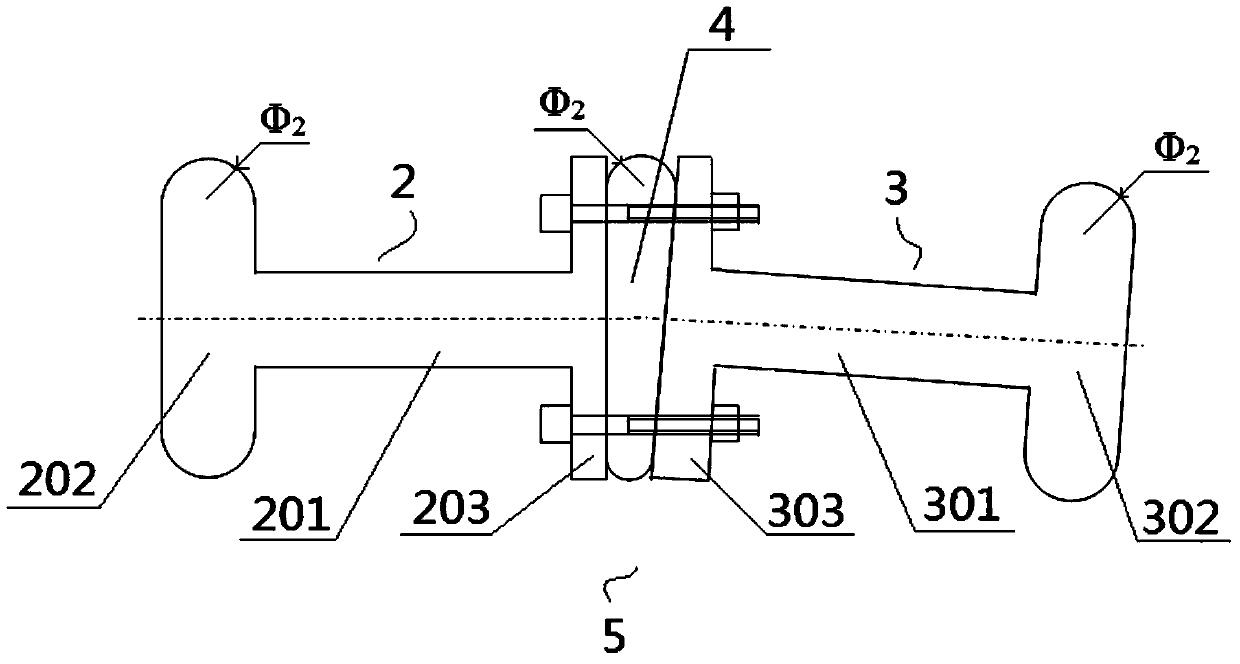

[0038] Curvature calibration gauge 5 such as figure 2 As shown, it includes a reference gauge 2, a spherical gauge 3 and a wedge gauge 4, and the reference gauge 2 and the spherical gauge 3 are respectively located on both sides of the wedge gauge 4.

[0039] The middle part of said reference gauge 2 is a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com