Micro nano step standard template and tracking method thereof

A standard template, micro-nano technology, used in measuring devices, instruments, and the use of wave/particle radiation, etc., can solve the problems of small field of view, cumbersome calibration work, blurry, etc., to improve measurement efficiency, facilitate calibration work, and accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

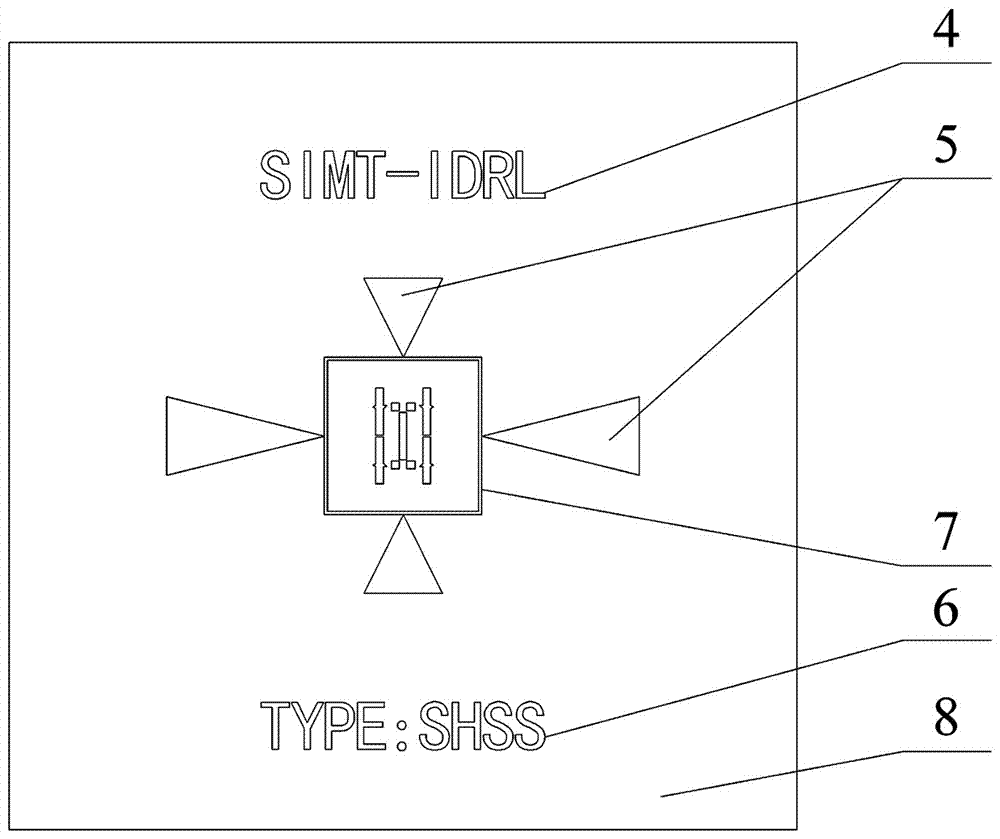

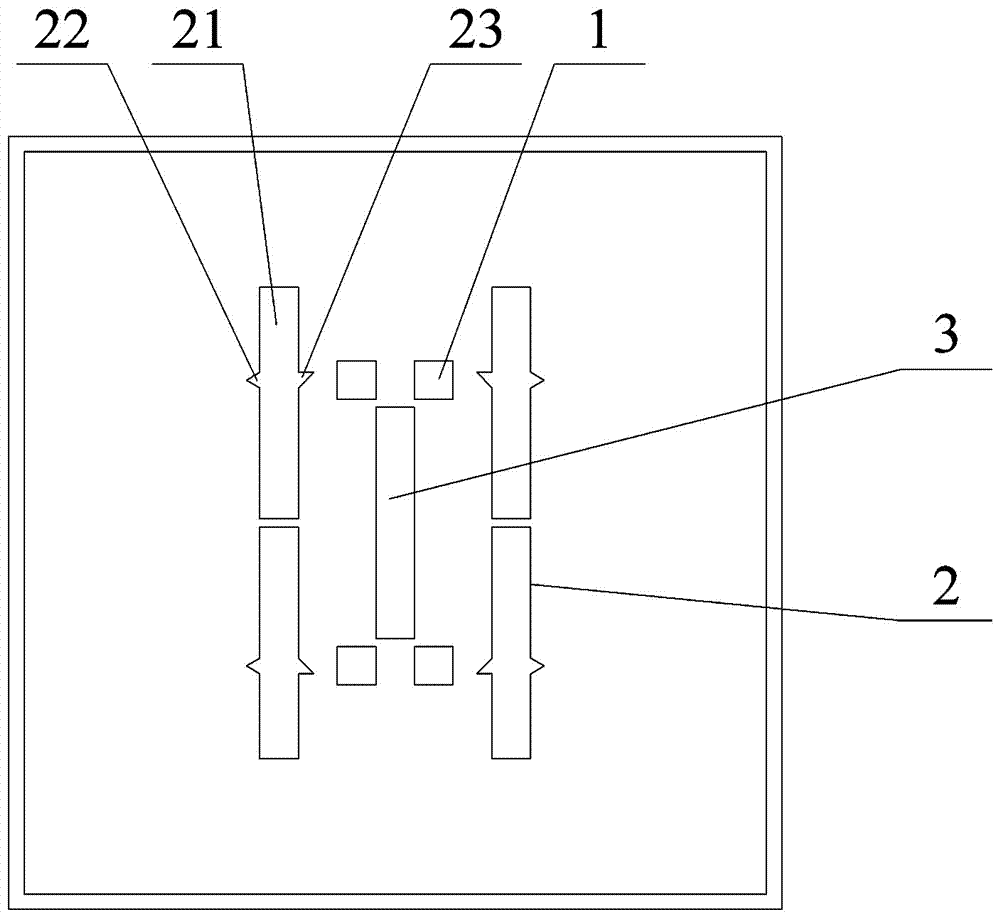

[0024] According to the attached figure 1 and attached figure 2 , the overall structure of the micro-nano step standard template of the present invention is designed as a square shape with a side length of 5mm. The central area of the micro-nano step standard template is provided with an A working area 7, the A working area 7 is a square area with a side length of 1 mm, and its frame width is designed to be 20 μm. The heights of other structures used for positioning are all designed to be 100 nm. A nanoscale standard step 3 is set at the center of the A working area 7 with a length of 300 μm and a width of 50 μm. Four calibration positioning blocks 1 are arranged corresponding to the four corners of the nano-level steps 3. The calibration positioning blocks 1 are square positioning blocks with a side length of 50 μm. The short sides of 3 overlap and are arranged in the shape of "I". Four tracking reference positioning blocks 2 are symmetrically arranged on the left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com