Method for judging laser cleaning effect

A laser cleaning and determination method technology, applied in the field of laser cleaning, can solve problems such as difficult to realize online monitoring, low detection speed rate, complex algorithm, etc., and achieve the effects of reducing damage risk, efficient cleaning, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

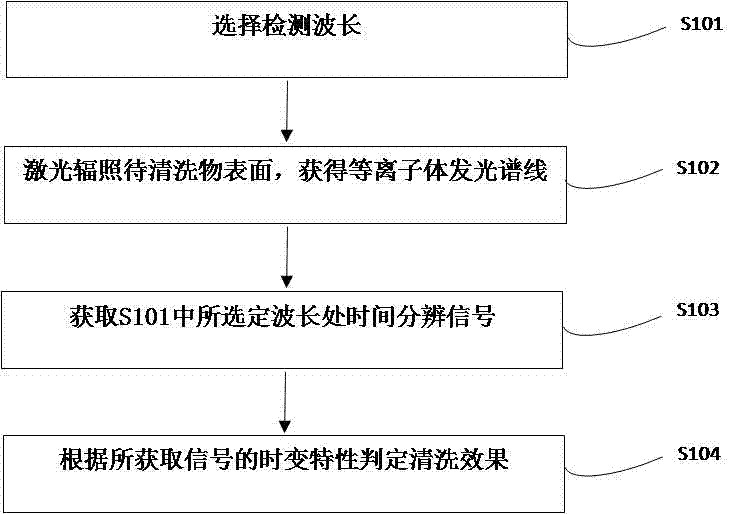

Method used

Image

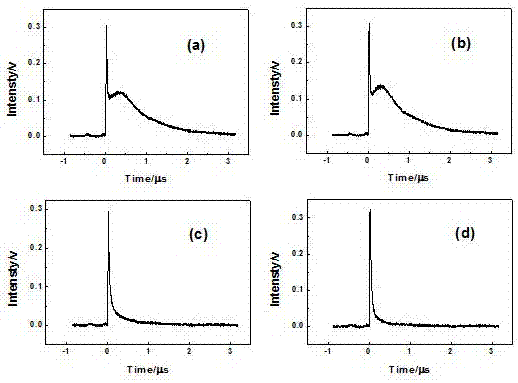

Examples

Embodiment 1

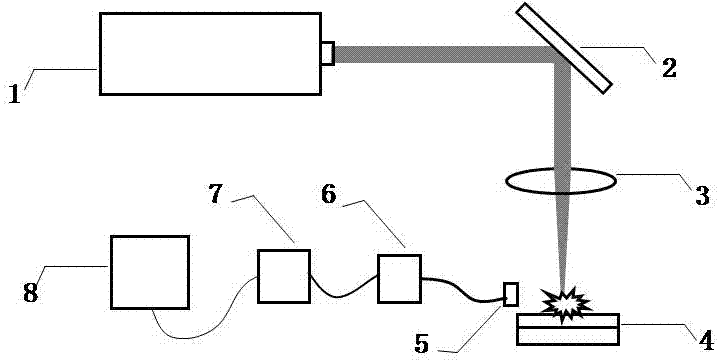

[0028] In this embodiment, the laser 1 adopts a Q-switched Nd:YAG pulsed solid-state laser with a wavelength of 1064 nm, a pulse width of 7 ns, an adjustable frequency of 1-100 Hz, and an energy range of 0-100 mJ, which is focused on the white paint sample through a lens , so that it generates laser plasma; reflector 2 uses a dielectric coated lens with a total reflection of 1064nm wavelength of 45°; lens 3 uses a lens with a focal length of 200mm; the base plate of sample 4 uses an Al substrate, and the paint is protected The white automatic spray paint produced by Li Company is uniformly sprayed on the surface of the substrate with a thickness of about 150 µm; the fiber diameter of the optical fiber probe 5 is 400 µm; the spectral separation part 6 uses the grating spectrometer of the Princeton Instruments company model Acton SP2750; the photoelectric detector 7 adopts THORLABS company model APD430A2( / M) detector, detection range is 200-1000nm, bandwidth is 400MHz; high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com