Electric control system of small engine dismounting device

An engine, small technology, applied in the direction of electrical program control, general control system, control/regulation system, etc., can solve the problems of low degree of automation, low degree of automation, large interference, etc., to achieve automatic control and accurate The effect of positioning, improving the degree of automation and reliability, and improving the anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

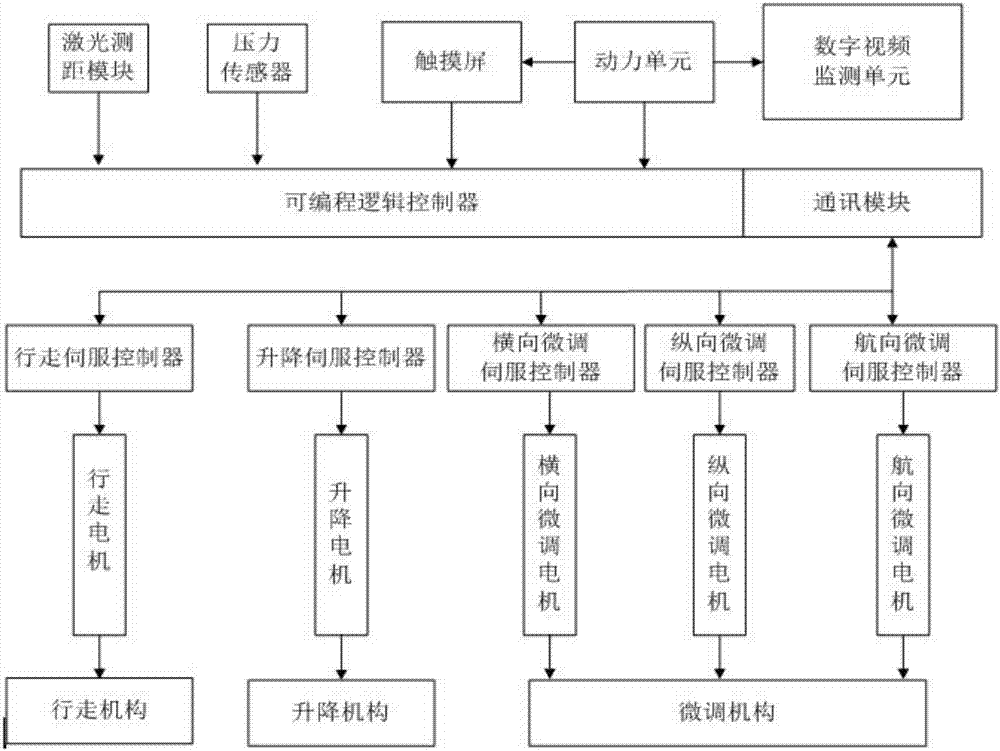

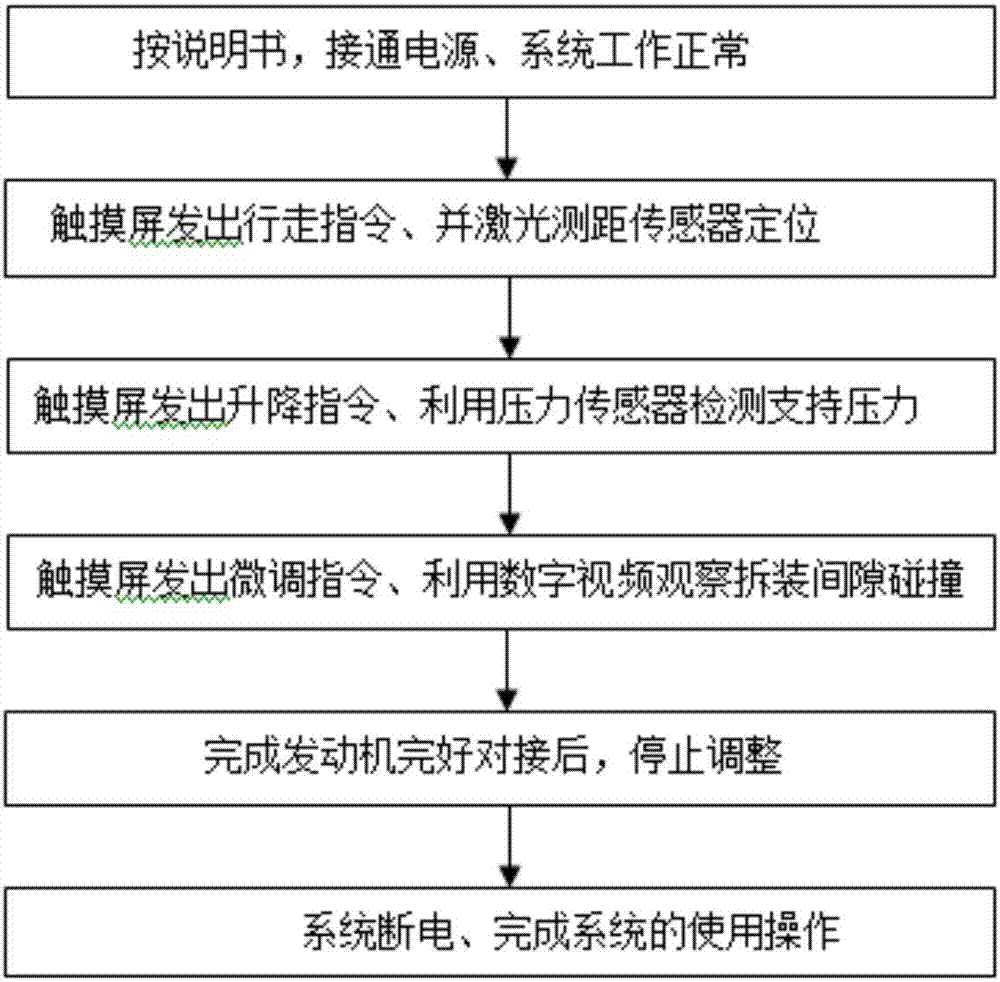

[0016] The control system consists of programmable logic controller, communication module, power unit, touch screen, laser distance measuring module, pressure sensor, digital video monitoring unit, walking servo controller, lifting servo controller, horizontal fine-tuning servo controller, vertical fine-tuning servo Controller, heading fine-tuning servo controller, walking motor, lifting motor, horizontal fine-tuning motor, vertical fine-tuning motor, horizontal fine-tuning motor, heading fine-tuning motor, traveling mechanism, lifting mechanism, fine-tuning mechanism group, etc.

[0017] The small aircraft engine dismounting device includes a bottom walking mechanism, a lifting mechanism in the middle, and a walking mechanism mechanically connected to the lifting mechanism. On the upper part of the lifting mechanism is a fine-tuning mechanism, and the lifting mechanism is mechanically connected to the fine-tuning mechanism to form a small aircraft engine dismounting device. Fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com