Drying device for leather dyeing

A drying device and leather technology, which is applied in leather drying, raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur processing, etc., can solve the problems of uneven drying of leather and difficulty in controlling the degree of drying of leather, etc. to prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

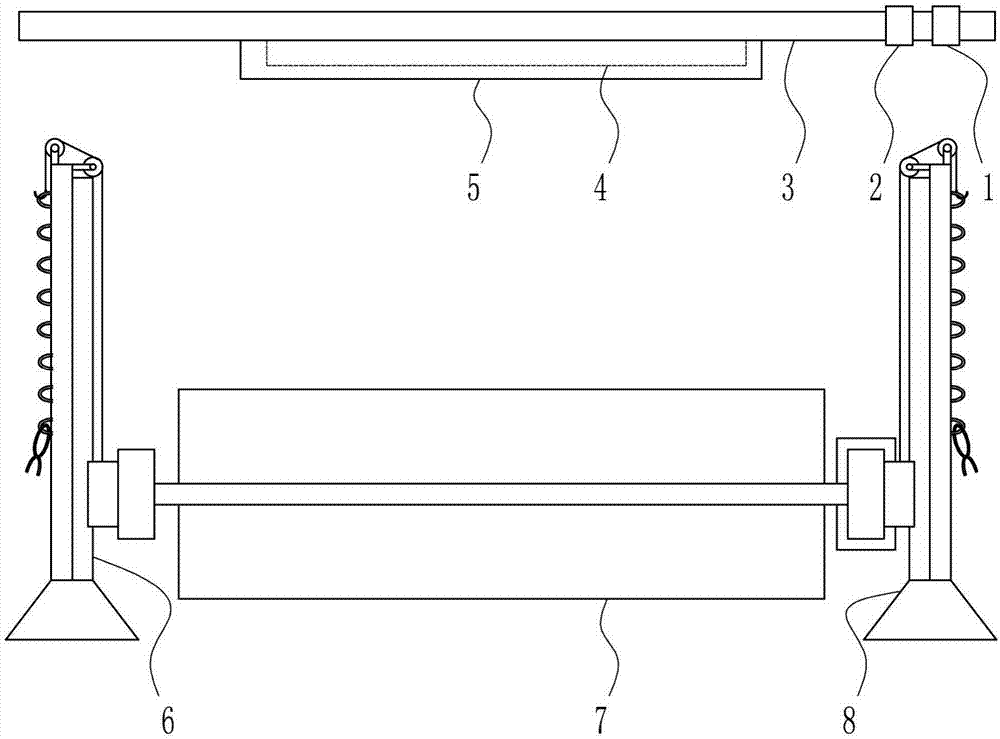

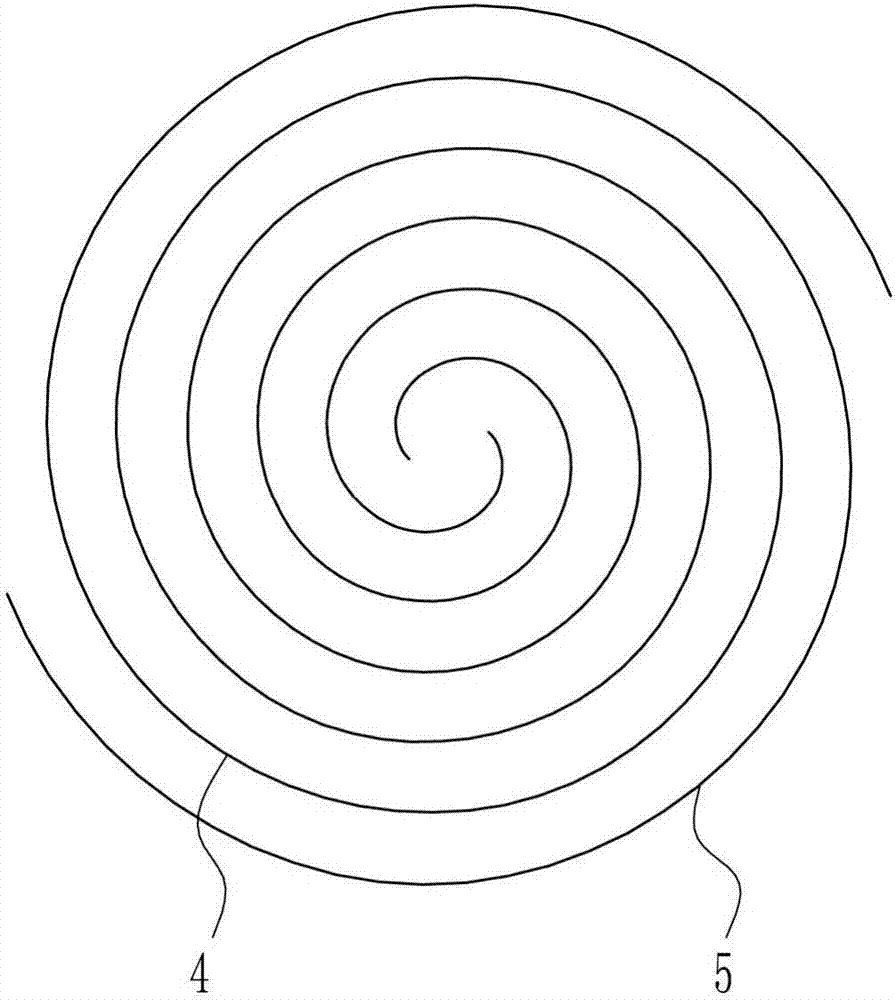

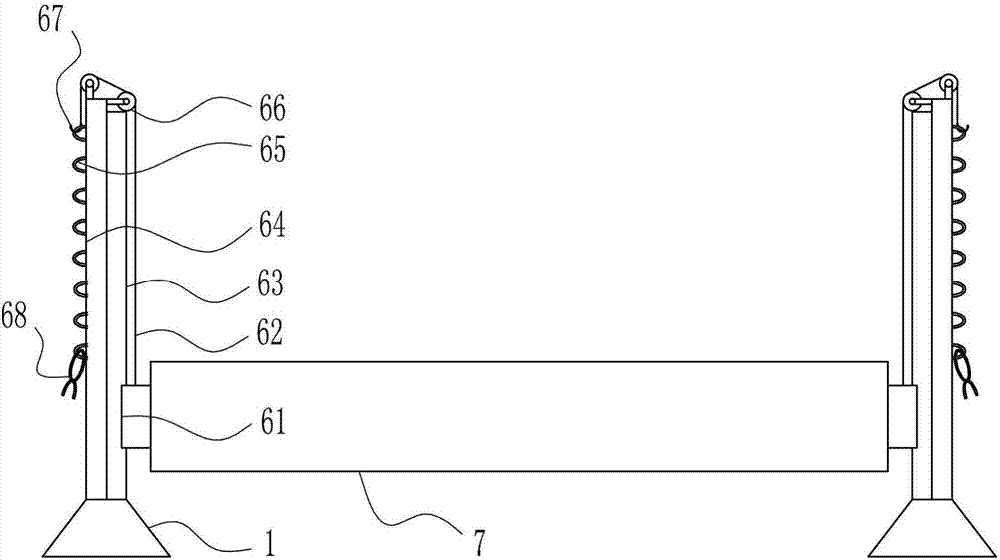

[0043] A drying device for leather dyeing, such as Figure 1-10 As shown, it includes a first switch 1, a second switch 2, a top plate 3, a first electric heating tube 4, a second electric heating tube 5, a lifting device 6, a rotating device 7 and a base 8, and the bottom of the top plate 3 is provided with a first electric heating tube. The tube 4 and the second electric heating tube 5, the first electric heating tube 4 is arranged inside the second electric heating tube 5, the right end of the front side of the top plate 3 is provided with a first switch 1 and a second switch 2, and the first switch 1 is arranged on the second switch 2, the first switch 1 is connected to the first electric heating tube 4, the second switch 2 is connected to the second electric heating tube 5, and the left and right sides below the top plate 3 are symmetrically provided with a base 8, and the base 8 is provided with The lifting device 6 is provided with a rotating device 7 on the lifting dev...

Embodiment 2

[0045] A drying device for leather dyeing, such as Figure 1-10 As shown, it includes a first switch 1, a second switch 2, a top plate 3, a first electric heating tube 4, a second electric heating tube 5, a lifting device 6, a rotating device 7 and a base 8, and the bottom of the top plate 3 is provided with a first electric heating tube. The tube 4 and the second electric heating tube 5, the first electric heating tube 4 is arranged inside the second electric heating tube 5, the right end of the front side of the top plate 3 is provided with a first switch 1 and a second switch 2, and the first switch 1 is arranged on the second switch 2, the first switch 1 is connected to the first electric heating tube 4, the second switch 2 is connected to the second electric heating tube 5, and the left and right sides below the top plate 3 are symmetrically provided with a base 8, and the base 8 is provided with The lifting device 6 is provided with a rotating device 7 on the lifting dev...

Embodiment 3

[0048] A drying device for leather dyeing, such as Figure 1-10 As shown, it includes a first switch 1, a second switch 2, a top plate 3, a first electric heating tube 4, a second electric heating tube 5, a lifting device 6, a rotating device 7 and a base 8, and the bottom of the top plate 3 is provided with a first electric heating tube. The tube 4 and the second electric heating tube 5, the first electric heating tube 4 is arranged inside the second electric heating tube 5, the right end of the front side of the top plate 3 is provided with a first switch 1 and a second switch 2, and the first switch 1 is arranged on the second switch 2, the first switch 1 is connected to the first electric heating tube 4, the second switch 2 is connected to the second electric heating tube 5, and the left and right sides below the top plate 3 are symmetrically provided with a base 8, and the base 8 is provided with The lifting device 6 is provided with a rotating device 7 on the lifting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com