Single-gear-ring dry-friction external-control three-gear transmission

A technology of dry friction and transmission, which is applied in the direction of clutches, couplings, gear transmissions, etc. It can solve the problems of large radial and axial dimensions of transmissions, long response time, and large shifting impact, so as to improve service life and stability performance, quicker response time, and better shifting smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

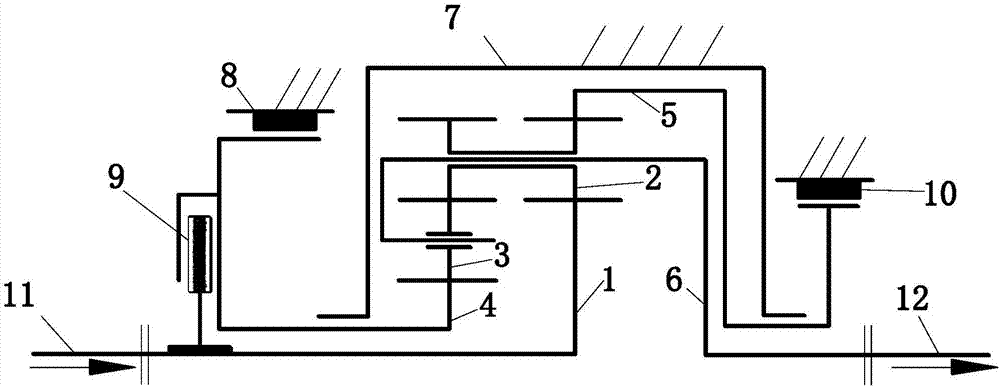

[0034] Please also refer to figure 1 ,Such as figure 1 It can be seen that a preferred embodiment of the present invention is a single ring gear dry friction externally controlled three-speed transmission, including a shift control element outside the box and a planetary gear transmission, and the planetary gear transmission includes The first gear set, the second gear set, the planet carrier 6, the ring gear 5 and the case 7; the first gear set includes the first sun gear 4 and the first planetary gear 3 meshing with the first sun gear 4; the The second gear set includes the second sun gear 1 fixed on the power input shaft 11 and the second planetary gear 2 meshed with the second sun gear, and the second planetary gear is also meshed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com