Roasting furnace device

A roasting furnace and kiln technology, applied in the roasting furnace field, can solve the problems of low degree of intelligent control, high heat loss, serious pollution, etc., achieve the effect of easy use, easy disassembly and installation, and improve heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

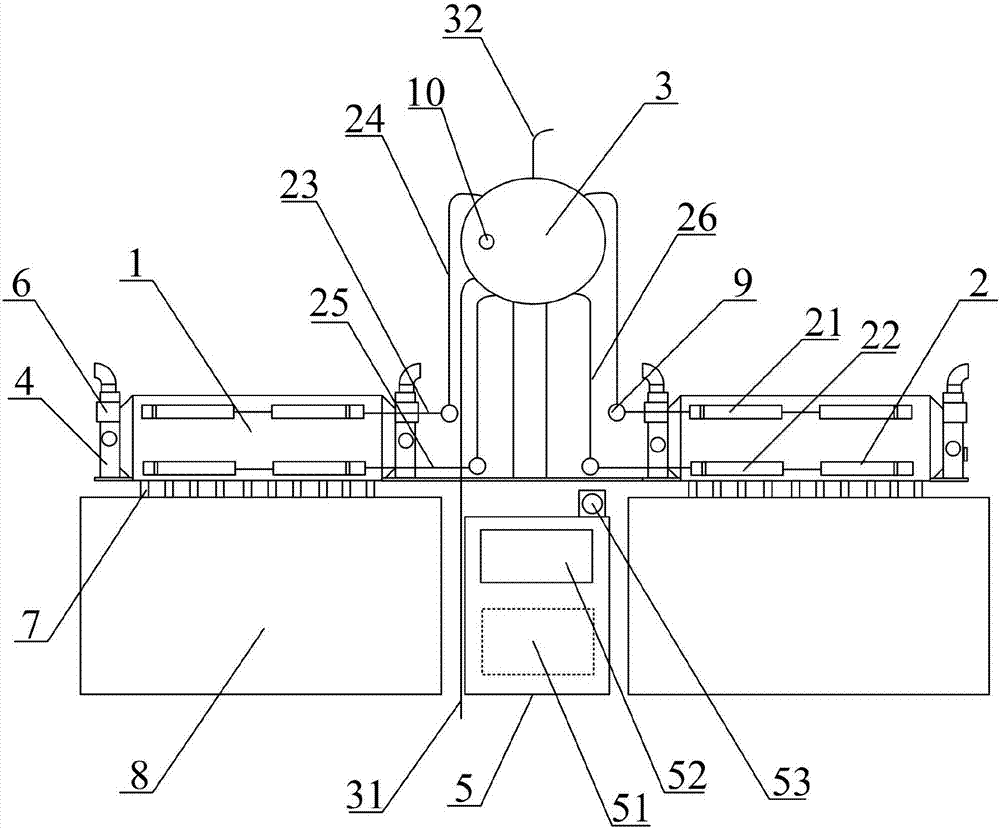

[0031] as attached figure 1 to attach image 3 shown

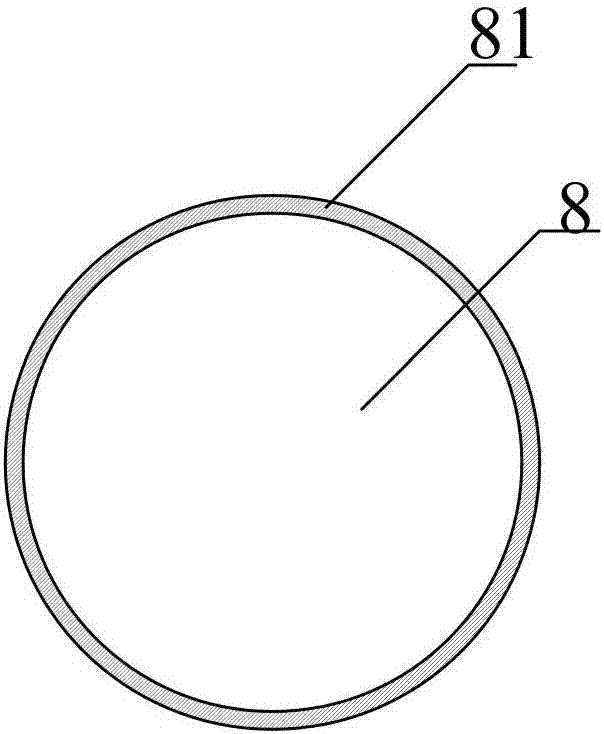

[0032] The present invention provides a roasting furnace device, comprising a flue 1, a steam generator 2, a steam-water separator 3, a chimney 4, a control box 5 and a frequency conversion fan 6, and the flue 1 is connected to the kiln through the smoke inlet 7 8 connected; the steam generator 2 is integrated installed in the kiln 8 and communicated with the steam-water separator 3; the steam-water separator 3 is set outside the flue 1; the smoke exhaust pipe 4 is set in the flue 1 The two ends; the control box 5 is electrically connected with the steam generator 2, the steam-water separator 3 and the smoke exhaust tube 4; the frequency conversion fan 6 is installed on the smoke exhaust tube 4.

[0033] In the above embodiment, specifically, the flue 1 is arranged horizontally.

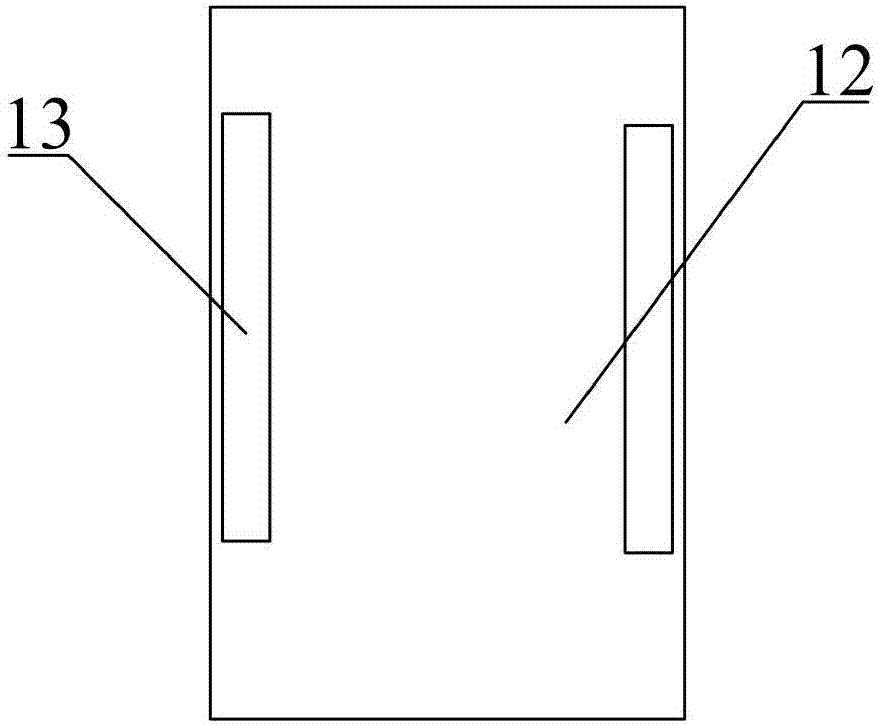

[0034] In the above embodiment, specifically, the steam generator 2 is divided into an upper steam generator 21 and a lower steam generator 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com