A kind of copper molybdenum dioxide graphene composite material and its preparation method and application

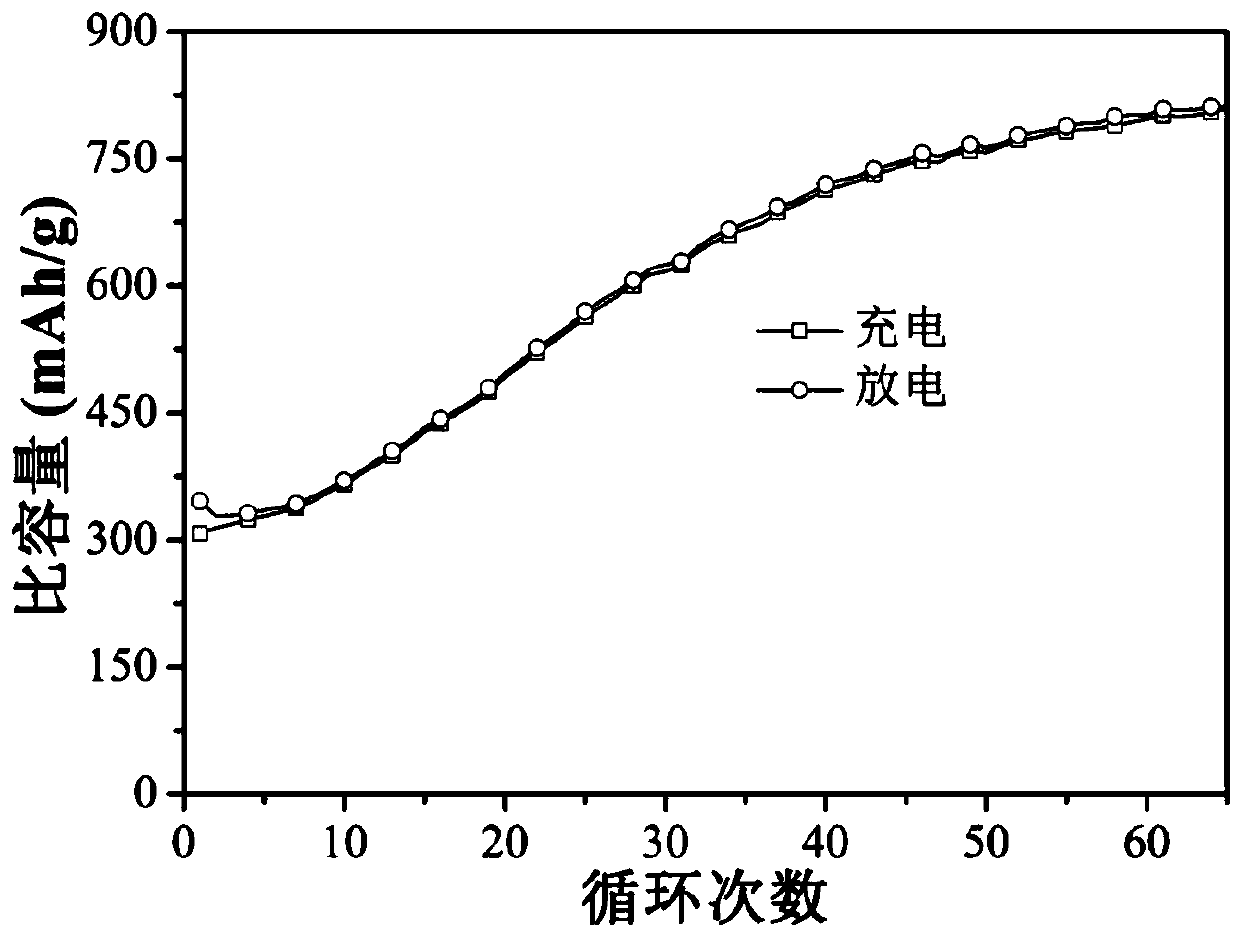

A molybdenum dioxide and composite material technology, applied in secondary batteries, electrochemical generators, structural parts, etc., can solve the problems of low reversible capacity, poor cycle stability, etc., and achieve good Coulomb efficiency, low cost, and good electrochemical performance. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

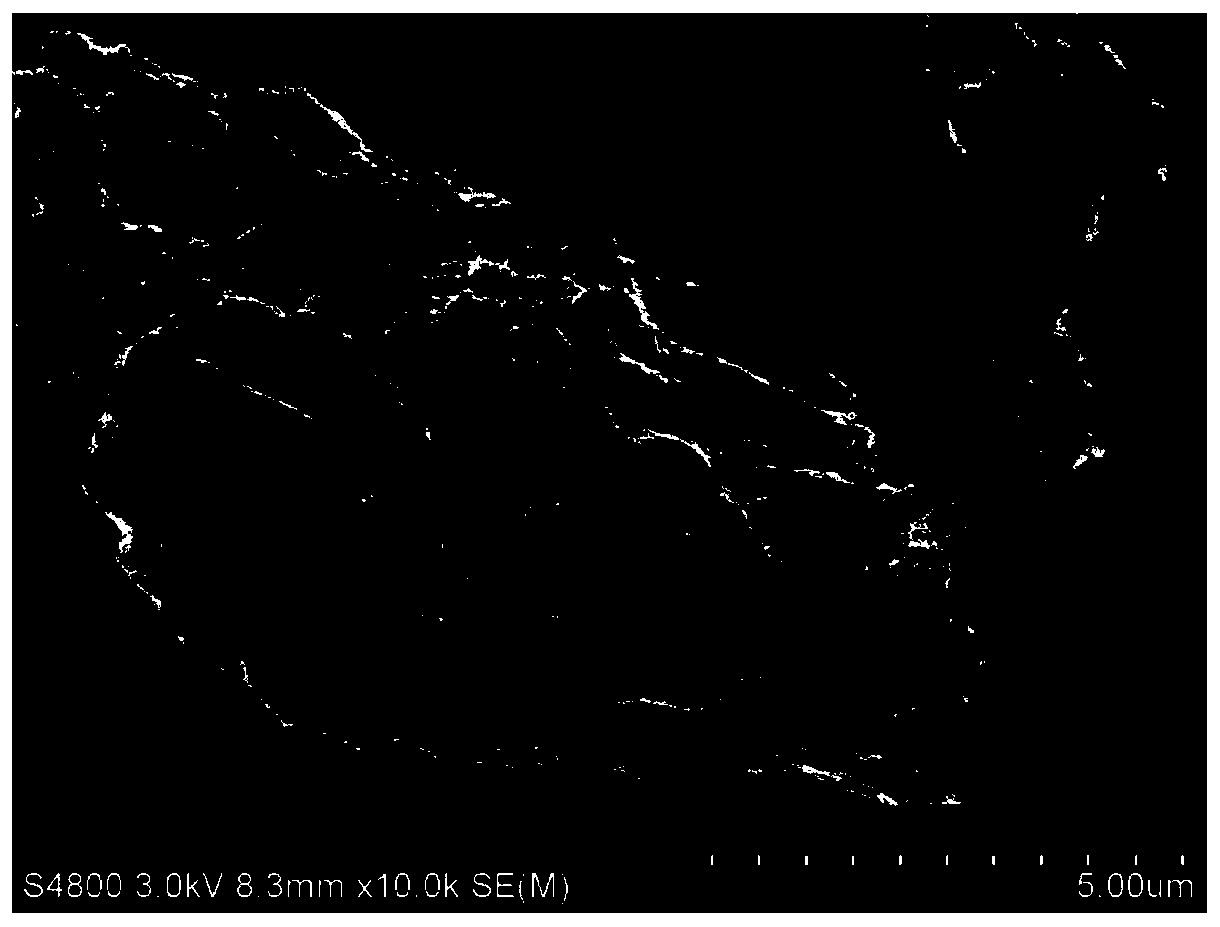

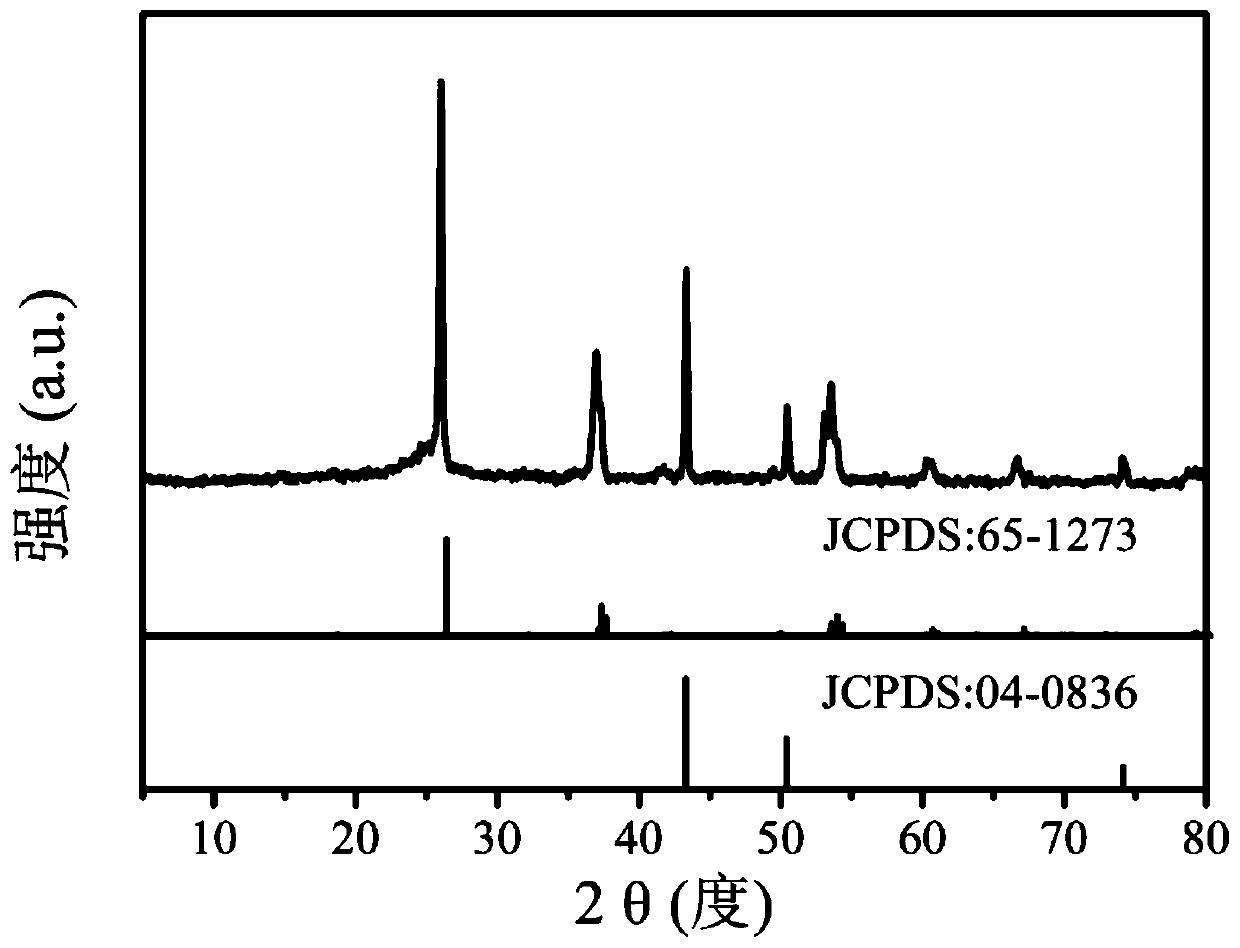

[0032] see Figure 1-3 , the preparation method of copper-molybdenum-molybdenum-graphene composite material of the present invention, comprises the following steps:

[0033] 1) Add ammonium molybdate tetrahydrate and copper acetate dihydrate into the sodium hydroxide aqueous solution with a concentration of 0.001-0.005mol / L according to the molar ratio of (1-3):1, and heat it at a temperature of 120-160°C React for 3-5 hours, and then perform centrifugation, washing and drying to obtain copper molybdate nanoparticles and product A;

[0034] 2) preparing a graphene oxide aqueous solution with a concentration of 0.5 to 1 mol / L;

[0035] 3) Mix the product A and the graphene oxide aqueous solution uniformly according to the mass ratio of 20:(1~20), stir and sonicate for 0.5~1h until the mixture is uniform, and then rotate the product at a temperature of 60~80°C , dry treatment, obtain product B;

[0036] 4) Calcining the product B under an argon atmosphere at 500-800° C. for 1...

Embodiment 1

[0039] 1) Ammonium molybdate tetrahydrate and copper acetate dihydrate were dissolved in 40 mL, 0.001 mol / L sodium hydroxide aqueous solution according to the molar ratio of 1:1, hydrothermally reacted at 120°C for 3 hours, the product was centrifuged, washed and dried to obtain product A;

[0040] 2) preparing a graphene oxide aqueous solution with a concentration of 0.5 mol / liter to obtain product B;

[0041] 3) Take A and component B with a mass ratio of 1:1 and mix evenly, stir and sonicate for 0.5 hours, and the product is rotary evaporated and dried at 60°C.

[0042] 4) Calcining the product at 500° C. for 1 hour under an argon atmosphere to obtain a copper-molybdenum-molybdenum-graphene composite material.

Embodiment 2

[0044] 1) Ammonium molybdate tetrahydrate and copper acetate dihydrate were dissolved in 40mL, 0.005 mol / L sodium hydroxide aqueous solution at a molar ratio of 1:1, hydrothermally reacted at 140°C for 3 hours, the product was centrifuged, washed and dried to obtain product A;

[0045] 2) preparing a graphene oxide aqueous solution with a concentration of 1 mol / liter to obtain product B;

[0046] 3) Take A and component B with a mass ratio of 2:1 and mix evenly, stir and sonicate for 0.5 hours, and the product is rotary evaporated and dried at 80°C.

[0047] 4) Calcining the product at 800° C. for 2 hours under an argon atmosphere to obtain a copper-molybdenum-molybdenum-graphene composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com