SRF production method using landfill waste and new domestic waste and recycling landfill method of landfill

A technology of domestic waste and production method, applied in the field of SRF production and landfill recycling landfill using landfill waste and new domestic waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, configurations and functions thereof as embodiments of the present invention will be described in detail with reference to the drawings. In addition, in describing the present invention, when it is judged that a related well-known function or a specific description of a configuration unnecessarily obscures the gist of the present invention, the detailed content will be omitted.

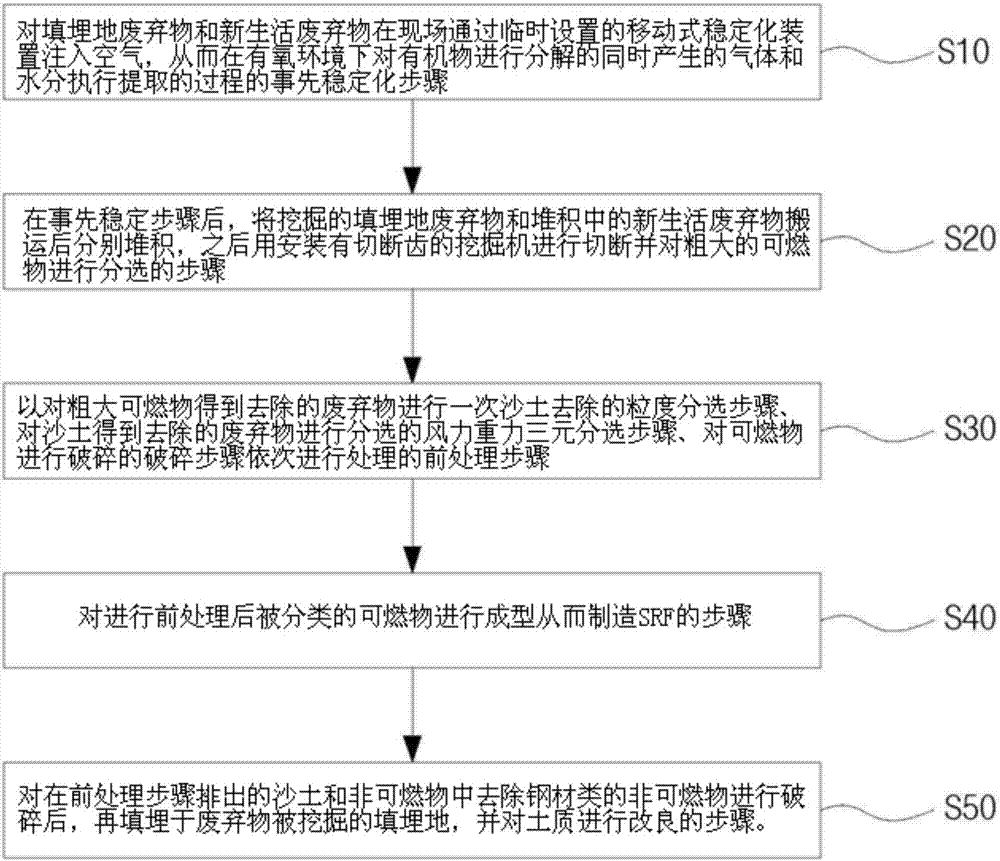

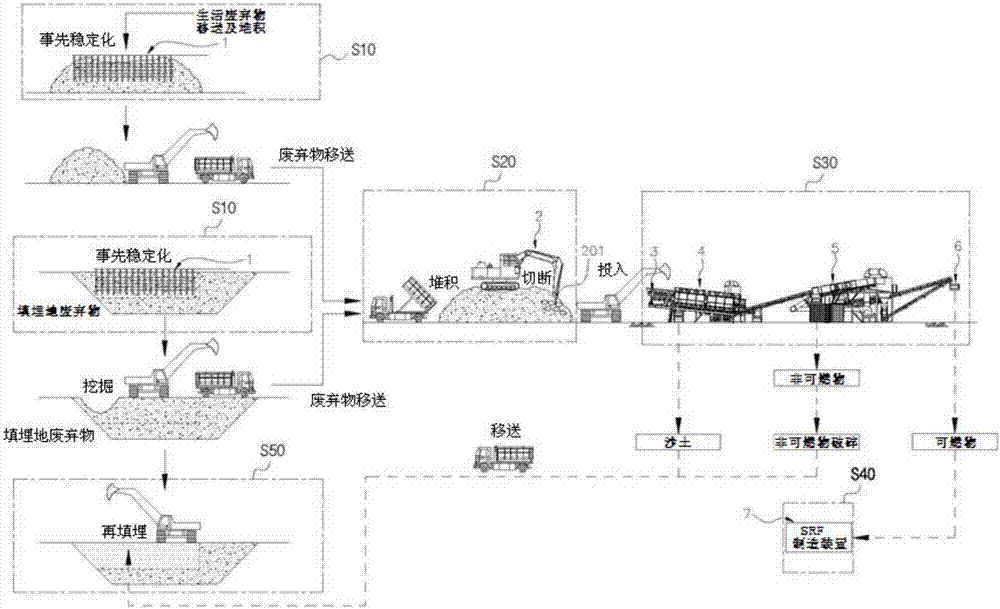

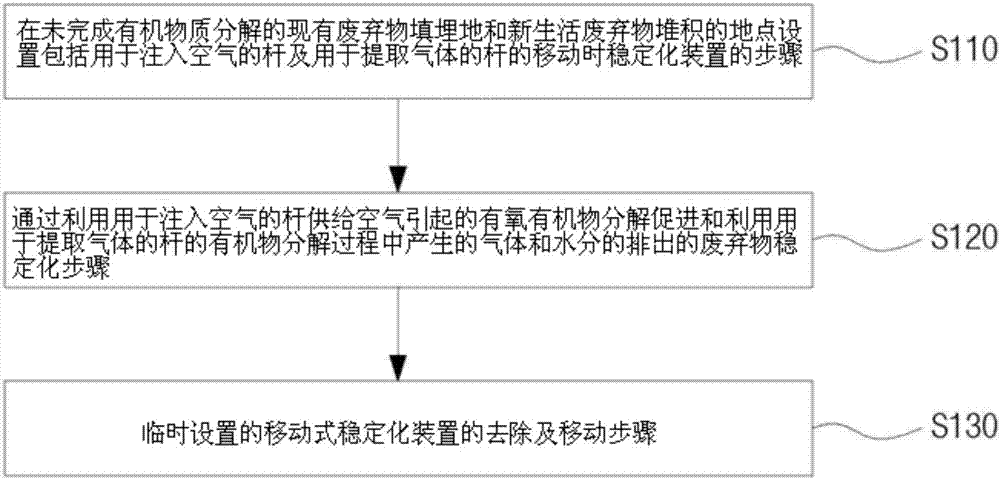

[0041] figure 1 is an overall process sequence diagram of a refill process for producing raw materials for manufacturing SRF and including sand and soil discharged in SRF production according to an embodiment of the present invention, figure 2 is based on figure 1 The overall device configuration diagram of the implementation of the overall process sequence of the present invention.

[0042] Referring to the figure, the present invention is roughly a group of inventions that organically combine the SRF production method through the prior stabilization of landfill waste, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com