Oil sealing device of steel cable component

A technology of oil seals and parts, which is applied in the field of aviation manufacturing engineering/aircraft assembly, can solve the problems of bloated and bulky containers for steel cable parts with a degree of freedom of rotation, difficulty in oil seal work for large aircraft cable parts, and occupied heating space, etc., to improve self-processing High capacity, complete functions, and the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

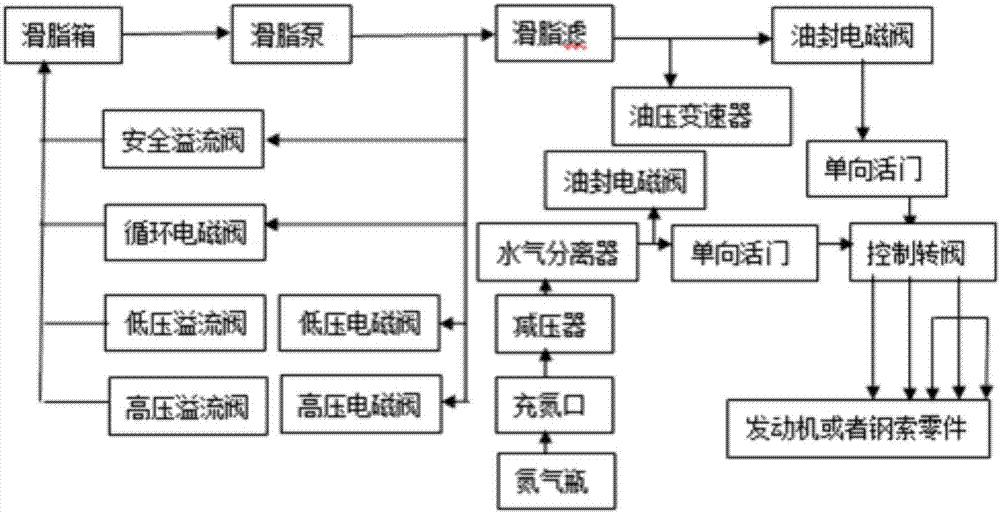

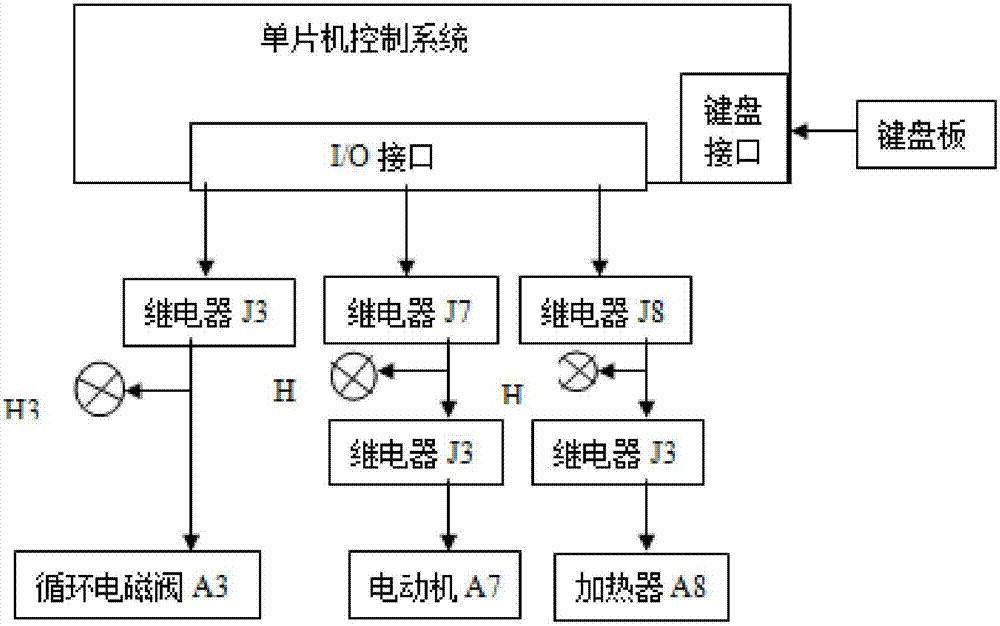

Method used

Image

Examples

Embodiment

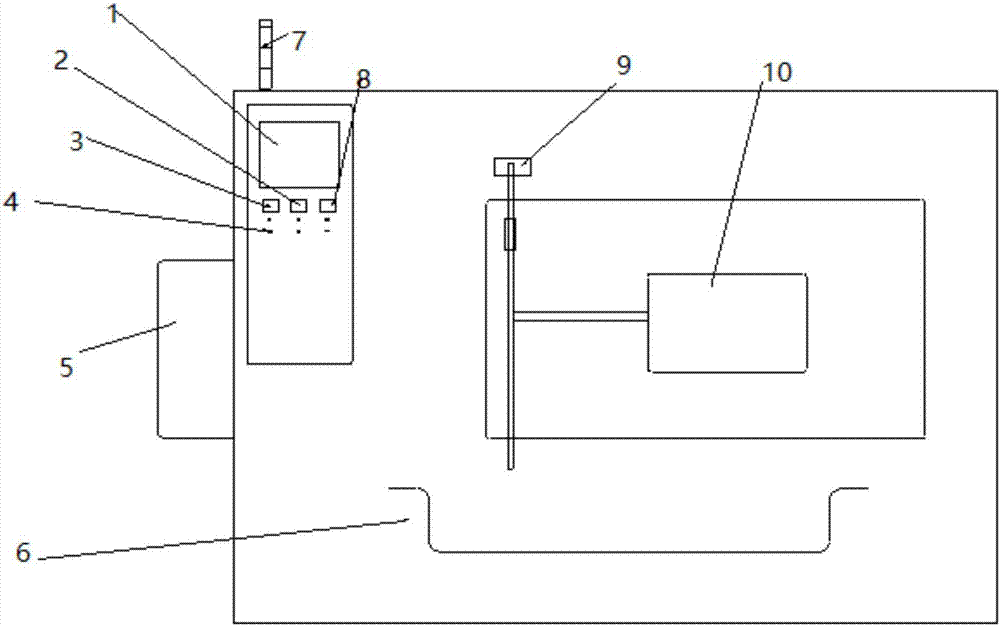

[0027] An oil seal device for steel cable parts, the effective working area size is 1000mm×800mm×600mm (length×width×height), the steel cable parts are coated with a layer of grease without dead ends, and sent into the oil seal device on a tray Heating, the following will only take a simple cable part - wire rope oil seal as an example to explain the operation process of the oil seal.

[0028] The various parts of this oil seal device are mutually coordinated, and one is indispensable. The oil seal device of the cable part or the engine is a device for heating, which can be adjusted to the corresponding temperature, set a certain heat preservation time, and can be controlled by alarm or automatic power off. control.

[0029] The specific operation is as follows:

[0030] (1) Oil seal: immerse the steel wire rope in lubricating grease at a temperature of 110°C to 120°C for 3min to 5min, and then during storage and use, regularly renew the grease on the surface of the steel wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com