Vanillin-based high-heat-resistant flame-retardant epoxy resin rich in benzene rings and its preparation method and application

A technology of epoxy resin and vanillin, which is applied in the field of high heat-resistant and high-efficiency flame-retardant epoxy resin, its preparation, and the field of flame-retardant epoxy resin, can solve the problems of comprehensive performance such as heat resistance to be improved, and achieve industrialization Large-scale production, good controllability, and the effect of overcoming poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0039] Wherein, as a more specific embodiment of the present invention, the preparation method may include the following steps:

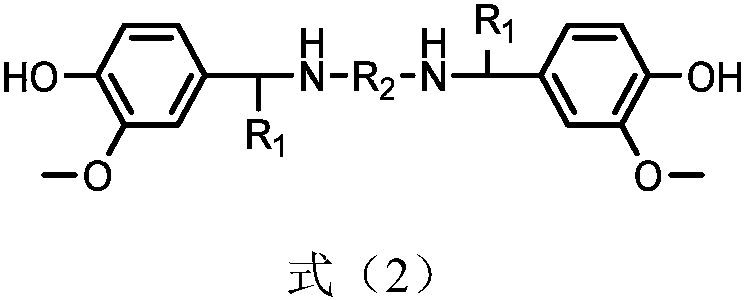

[0040] (1) Mix 100 parts by mass of vanillin, 10 to 100 parts by mass of diamine compounds, 20 to 300 parts by mass of phosphine reagent and 0 to 15 parts by mass of catalyst in 50 to 500 parts by mass of organic solvent. ℃ reaction for 0.5 to 24 hours, after the reaction is completed, distill, wash, dry and remove the solvent to obtain the phosphorus-containing bisphenol with vanillin group rich in benzene ring as shown in formula (2);

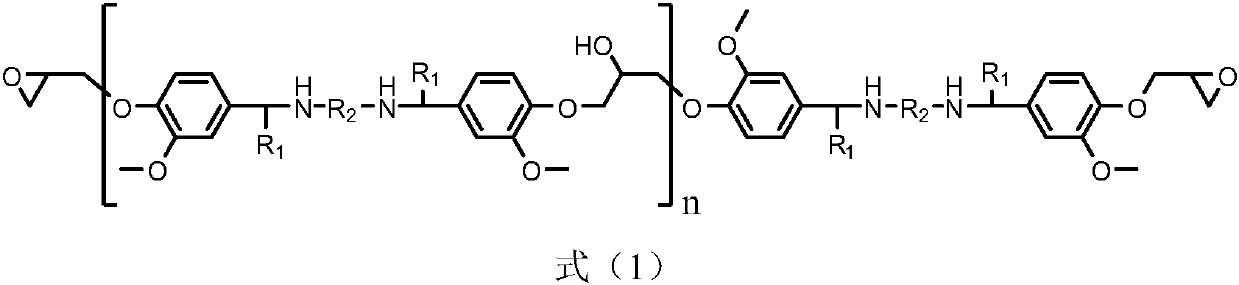

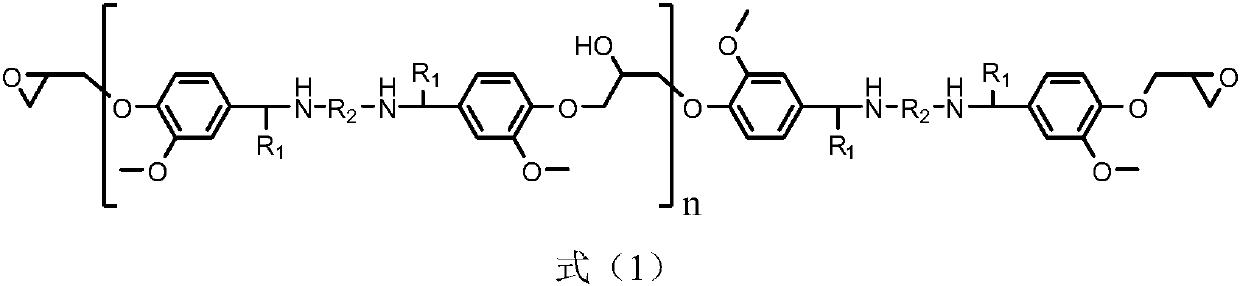

[0041] (2) Mix 100 parts by mass of the above vanillin-based phosphorous-containing bisphenol rich in benzene rings, 40-600 parts by mass of epichlorohydrin, and 30-300 parts by mass of basic substances, and then react at 20-130°C for 0.5 ~ 72 hours, after the reaction is finished, wash with water and distill to obtain a high heat-resistant and flame-retardant epoxy resin with vanillin group rich in benzene rings. ...

Embodiment 1

[0047] Example 1: Vanillin 100g, toluene 200g, 4,4'-biphenylenediamine 35g, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide 80g, pentachloride After mixing 10 g of niobium evenly, heat up to 30° C. for 24 hours, distill, wash with ethanol, and dry to obtain phosphorus-containing bisphenol with vanillin group rich in benzene rings as shown in the following formula (3). Then, 100 g of phosphorus-containing bisphenol rich in benzene ring in the vanillin group obtained above, 40 g of epichlorohydrin, and 80 g of lithium hydroxide aqueous solution of 20% (wt%, the same below) were mixed and reacted at 20° C. for 72 hours, After washing with water and distillation, the vanillin group-rich benzene ring-rich high heat-resistant and high-efficiency flame-retardant epoxy resin shown in the following formula (4) was obtained. According to the hydrogen nuclear magnetic resonance spectrum of the high heat-resistant and high-efficiency flame-retardant epoxy resin rich in benzene rings in...

Embodiment 2

[0050] Example 2: Oxidation of vanillin 100g, dimethylformamide 500g, 4,4'-diaminodiphenylmethane 10g, 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10- After mixing 20 g of the mixture evenly, heat up to 120° C. for 0.5 hour reaction, distill, wash with ethanol, and dry to obtain phosphorus-containing bisphenol rich in benzene rings in the vanillin group shown in the following formula (5). Then, 100 g of phosphorus-containing bisphenols rich in benzene rings in the vanillin group obtained above, 500 g of epichlorohydrin, 5 g of tetrabutylammonium bromide, and 295 g of 15% NaOH aqueous solution were mixed and reacted at 130° C. for 0.5 hour, and then reacted for 0.5 hours at 130° C. Washing with water and distillation obtains the high heat-resistant and high-efficiency flame-retardant epoxy resin rich in benzene rings in the vanillin group shown in the following formula (6). According to the hydrogen nuclear magnetic resonance spectrum of the high heat-resistant and high-efficienc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com