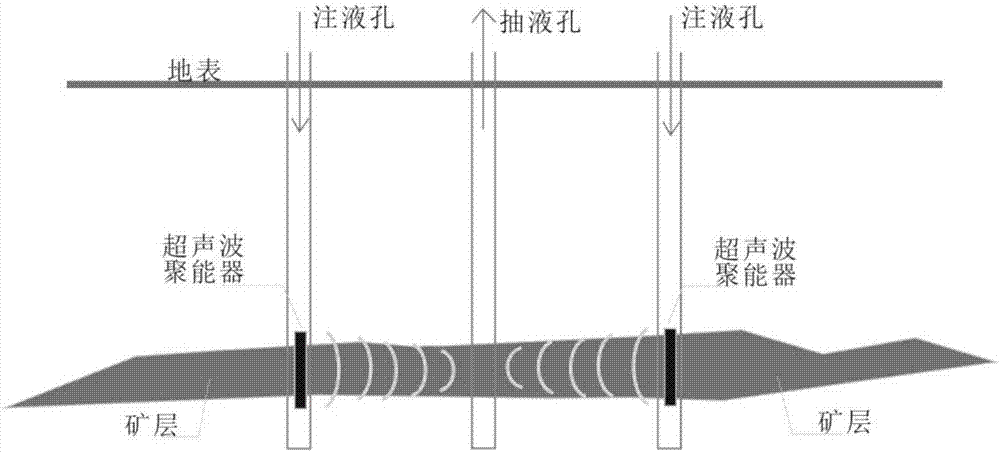

Method for improving leaching rate of in-situ leaching uranium mining using ultrasonic waves

A technology for in-situ leaching of uranium and ultrasonic waves, which is applied in the fields of mining fluids, earth-moving drilling, wellbore/well components, etc., to achieve the effects of improving oil recovery, improving permeability, and improving permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A sandstone-type uranium deposit in the Erlian Basin in northern my country, an expanded test well site for in-situ leaching.

[0027] The test period is 2 months, and the machine is turned on for 2 hours a day. During this period, 2 groups of "1 pumping and 4 injections" leaching units are selected. The distance between the two units is about 220m. unanimous. Unit A is equipped with an ultrasonic leaching device, and unit B is used for normal pumping and leaching in an ordinary way. The two units of A and B are incorporated into the pumping system at the same time for a comparative test.

[0028] Finally, the following conclusions were obtained. Before the test started, the permeability coefficients of units A and B were both about 0.2m / d, and the flow rate of the pumping hole was 3.5m 3 / h or so, the leachate concentration is about 18mg / L. When the power of the ultrasonic generator is 10Kw, after 2 months of ultrasonic leaching test, the permeability coefficient of ...

Embodiment 2

[0030] A sandstone-type uranium mine in Tianshan, Xinjiang, Northwest my country, mine field of in-situ leaching production plant.

[0031] The test period is 6 months, and the machine is turned on for 8 hours a day. During this period, two groups of "1 pumping and 4 injections" leaching units are selected. The distance between the two units is about 500m. unanimous. Unit A is equipped with an ultrasonic leaching device, and unit B is used for normal pumping and leaching in an ordinary way. The two units of A and B are incorporated into the pumping system at the same time for a comparative test.

[0032] Finally, the following conclusions were obtained. Before the test started, the permeability coefficients of units A and B were both about 0.2m / d, and the flow rate of the pumping hole was 3.0m 3 / h, the leachate concentration is about 10mg / L. When the power of the ultrasonic generator is 15Kw, after 6 months of ultrasonic leaching test, the permeability coefficient of the un...

Embodiment 3

[0034] In a sandy mudstone-type uranium deposit near Erenhot in northern my country, the in-situ leaching expanded test well site.

[0035] The test period is 4 months, and the machine is started for 5 hours a day. During this period, two groups of "1 pumping and 4 injections" leaching units are selected. The distance between the two units is about 300m. unanimous. Unit A is equipped with an ultrasonic leaching device, and unit B is used for normal pumping and leaching in an ordinary way. The two units of A and B are incorporated into the pumping system at the same time for a comparative test.

[0036] Finally, the following conclusions were obtained. Before the test started, the permeability coefficients of units A and B were both about 0.1m / d, and the flow rate of the pumping hole was 5m 3 / h or so, the leachate concentration is about 14mg / L. When the power of the ultrasonic generator is 30Kw, after 4 months of ultrasonic leaching test, the permeability coefficient of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com