Electric adsorption smoothing racket

An electric and motor technology, applied in the field of smoothing rackets, can solve the problems of high labor intensity, floating all over the sky, easy to break and short life span, and achieve good safety results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

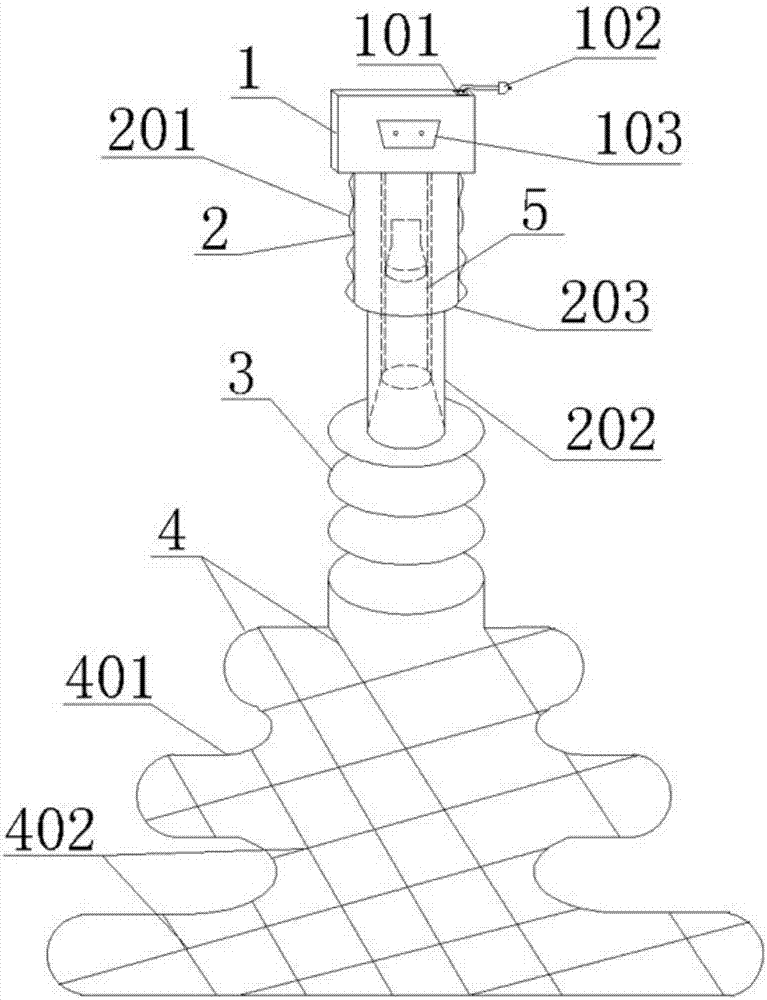

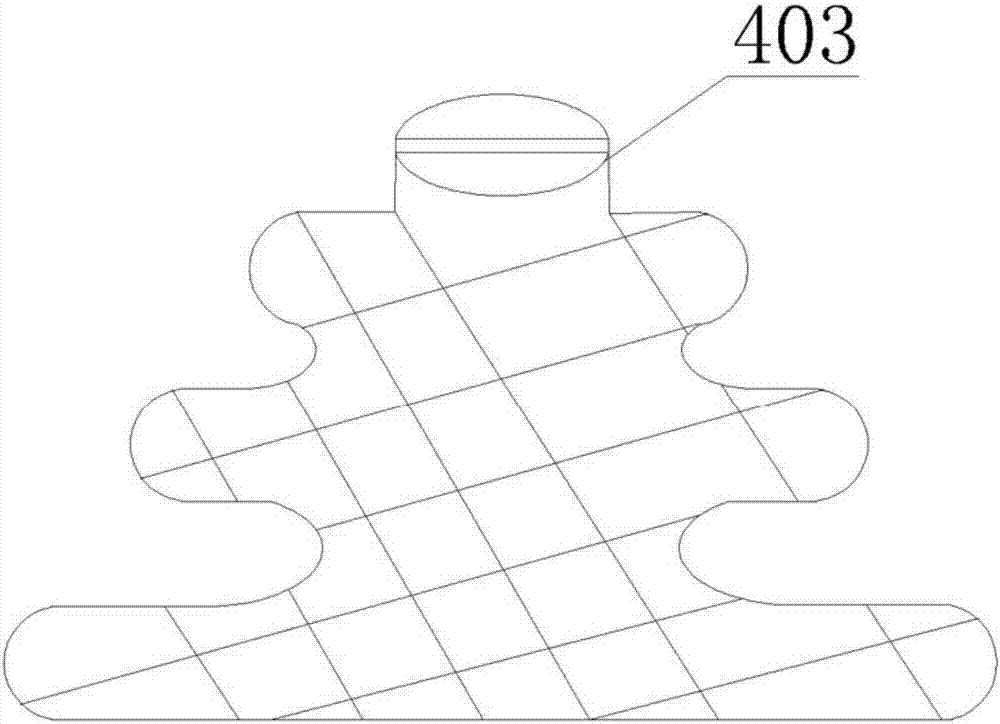

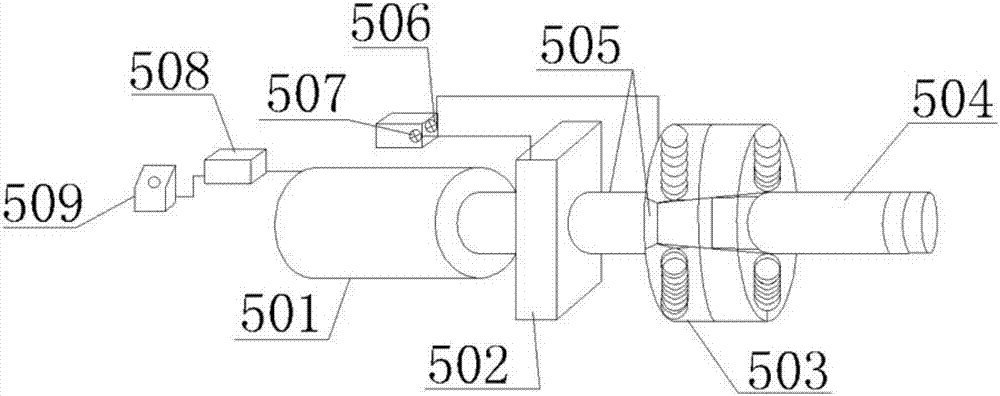

[0014] Referring to the accompanying drawings, an electric adsorption smoothing racket includes a handle 2, a transition soft connection 3, a racket head assembly 4, an electric oscillation system 5 and a protection alarm assembly 1, which is installed on the back of the handle 2. end, the handle 2 is a hollow structure, the electric oscillation system 5 is installed inside the handle 2, the electric oscillation system 5 is connected with the protection alarm assembly 1 and the racket head assembly 4, the transition soft connection 3 is fixed on the front end of the handle 2, and the racket head The component 4 is connected with the electric oscillation system 5 and the transition soft connection 3. The racket head component 4 is installed at the front end of the handle 2. The handle 2 is composed of an insulating rubber handle cover 201, a hollow stainless steel rod 203 and a hollow insulating inner sleeve 202. The hollow insulating inner sleeve 202 is installed inside the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com