Cavity subdivided type offshore infrastructure and construction method thereof

A basic structure and cavity technology, applied in basic structure engineering, construction, sheet pile wall, etc., can solve the problems of increasing the diameter or wall thickness of the pile foundation, poor geological properties of shallow surface soil, poor physical and mechanical properties, etc. The effect of improving stress characteristics, short construction period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

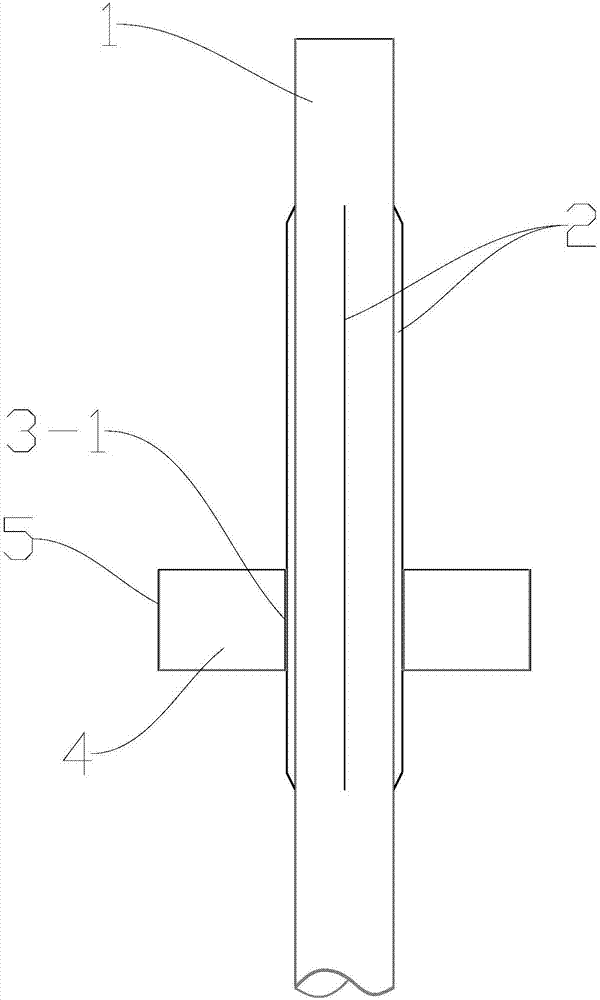

[0036] Embodiment 1: as figure 1 , figure 2 As shown, this embodiment is a cavity subdivided marine foundation structure, which is composed of steel pipe foundation piles 1 and a cavity structure, and is suitable for 6MW offshore wind turbines.

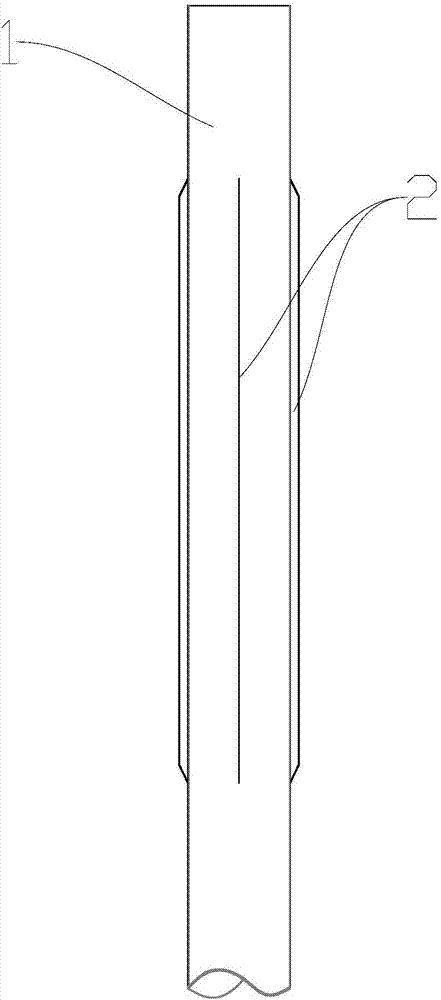

[0037] Such as image 3 Figure 4 As shown, steel pipe foundation pile 1 has a diameter of 4m and a single weight of 400t. Starting from 3m below the top of the pile, four slides 2 are evenly arranged on the side of the steel pipe foundation pile along the axial direction of the steel pipe foundation pile. The slides 2 are made of thick steel plates. The top of the slideway is arc-shaped. In this example, the steel pipe foundation pile 1 and the slideway 2 are welded in the factory.

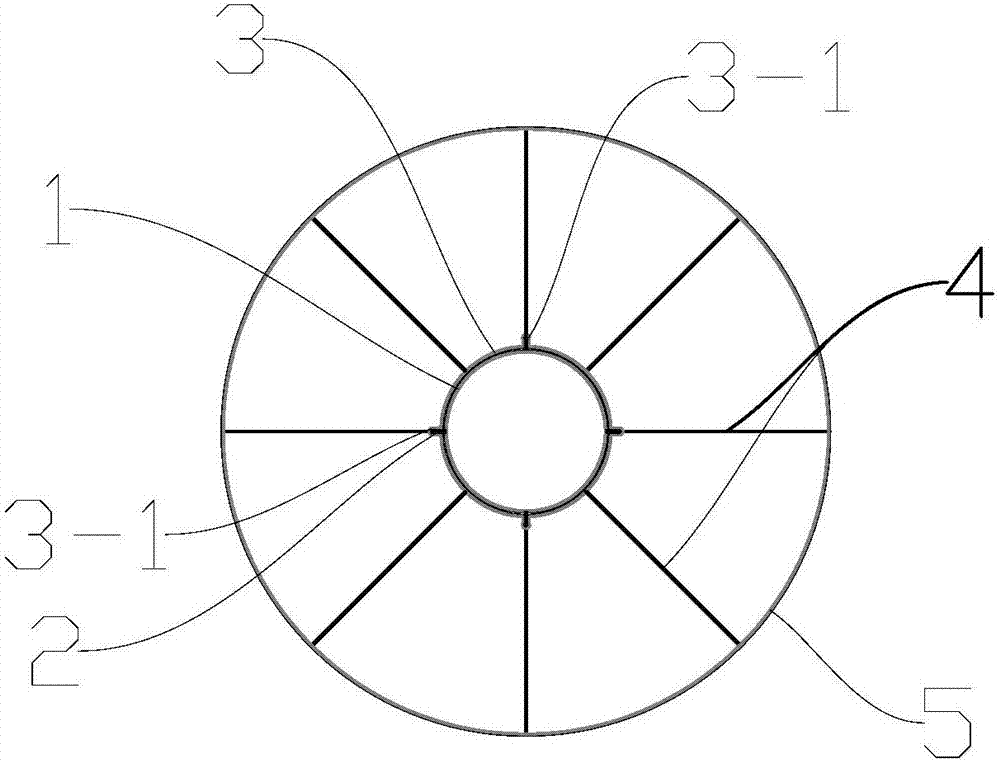

[0038] Figure 5 , Image 6 It is a schematic diagram of the cavity structure in this embodiment. The cavity structure has a circular tubular inner bulkhead 3 and a circular tubular outer bulkhead 5, wherein the diameter of the inner bulkhead 3 is ...

Embodiment 2

[0045] Embodiment 2: as Figure 7 , Figure 8 As shown, the present embodiment consists of two parts, the steel pipe foundation pile 1 and the cavity structure.

[0046] Steel pipe foundation pile 1 has a diameter of 4m and a single weight of 400t. Starting from 3m below the pile top, four slides 2 are evenly arranged on the side of the steel pipe foundation pile along the axial direction of the steel pipe foundation pile. The slides 2 are made of thick steel plates. The top of the slideway is arc-shaped. In this example, the steel pipe foundation pile 1 and the slideway 2 are welded in the factory.

[0047] In this embodiment, the cavity structure has a circular tubular inner bulkhead 3 and a circular tubular outer bulkhead 5, and an annular top bulkhead 6, and the center of the top bulkhead 6 has a hole that matches the size of the inner bulkhead 3. hole. Among them, the diameter of the inner bulkhead 3 is 4.01m (slightly larger than the diameter of the steel pipe foundat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com