Beam-to-column joints of prefabricated concrete frames based on partial high-strength bars

A prefabricated concrete and concrete beam technology, which is applied to buildings and building structures, etc., can solve the problems of insufficient shear resistance of beam-column joints, insufficient seismic performance, and inconvenient construction, and achieves improved seismic capacity and strong deformation capacity. , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

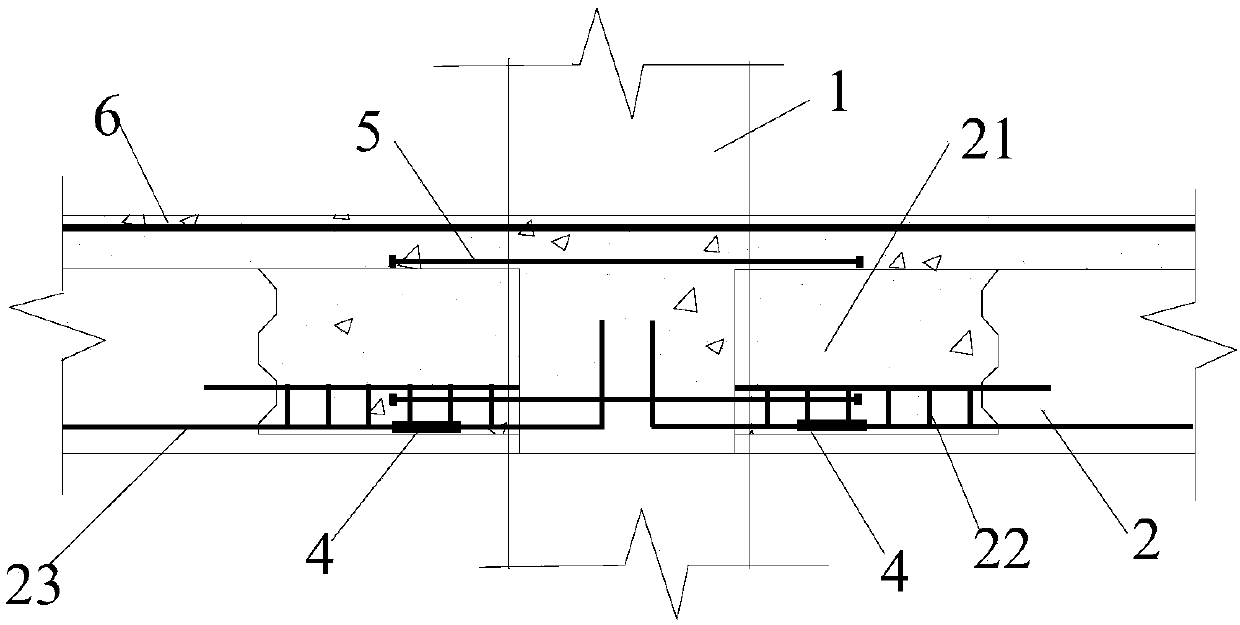

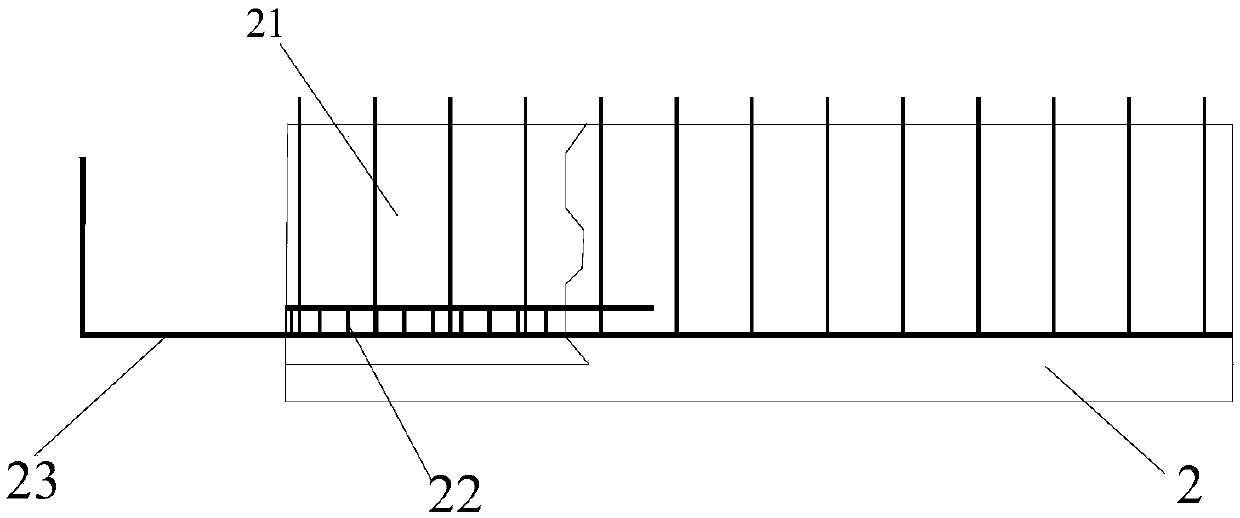

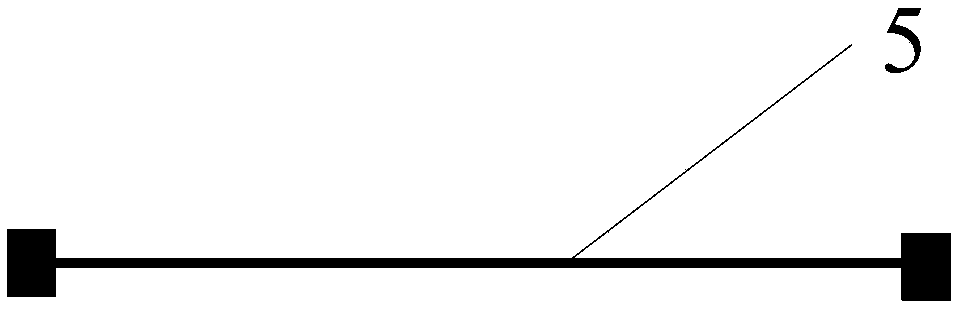

[0024] Such as figure 1 As shown, the present invention is based on some high-strength prefabricated concrete frame beam-column connection nodes, including prefabricated concrete columns 1 and prefabricated concrete beams 2, and one end of the concrete beams 2 rests on the concrete protective layer at the upper end of the concrete column 1 to form In the node core area 3, a U-shaped keyway 21 is left at the end of the concrete beam 2, and a core beam 22 and a PC steel rod 23 are arranged in the U-shaped keyway 21, and the free end of the PC steel rod 23 extends out of the concrete The end of the beam 2; the PVC pipe 4 is used in the keyway to do non-bonding treatment on the PC steel rod; the upper and lower parts of the core area 3 of the concrete beam 2 are respectively provided with short steel bars 5; the upper part of the concrete beam 2 is provided with Have the common steel bar 6 of full length.

[0025] The setting of the U-shaped keyway 21 can be determined comprehens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com