Assembled steel structure with replaceable beam end rotating energy-dissipating hinge and small oblique span lasso

A prefabricated, steel structure technology, applied in the direction of building components, building structures, protective buildings/shelters, etc., can solve the problems of overall stiffness reduction of components, cumulative plastic strain, secondary damage of steel beams, etc., to improve Anti-seismic performance, clear energy consumption mechanism, and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

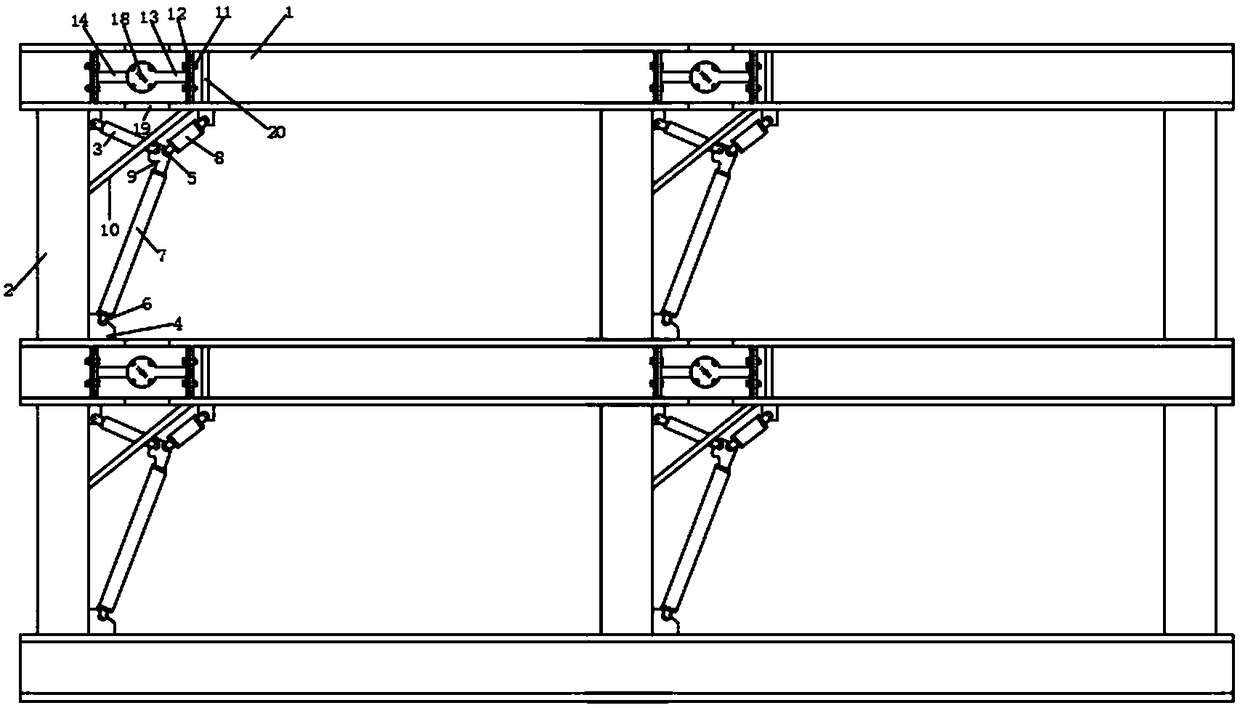

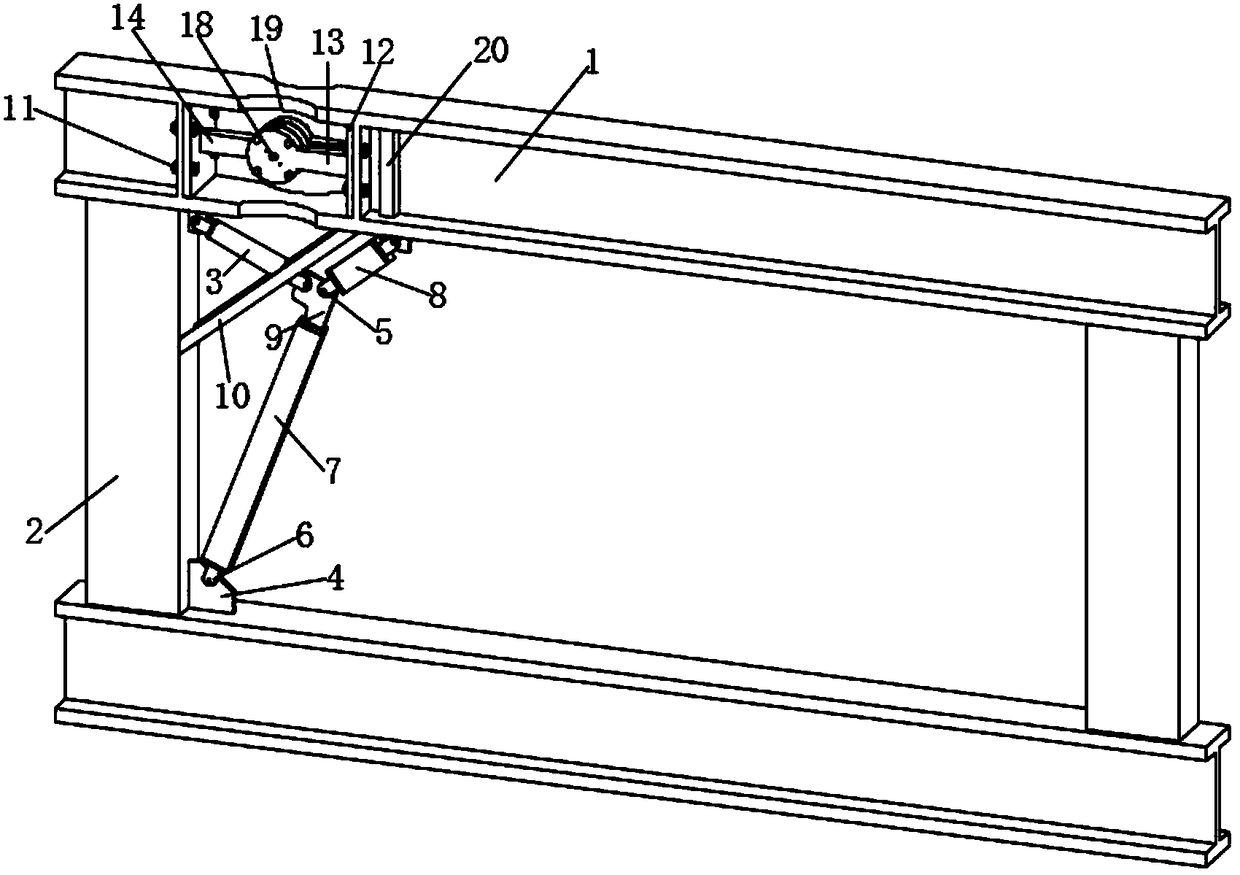

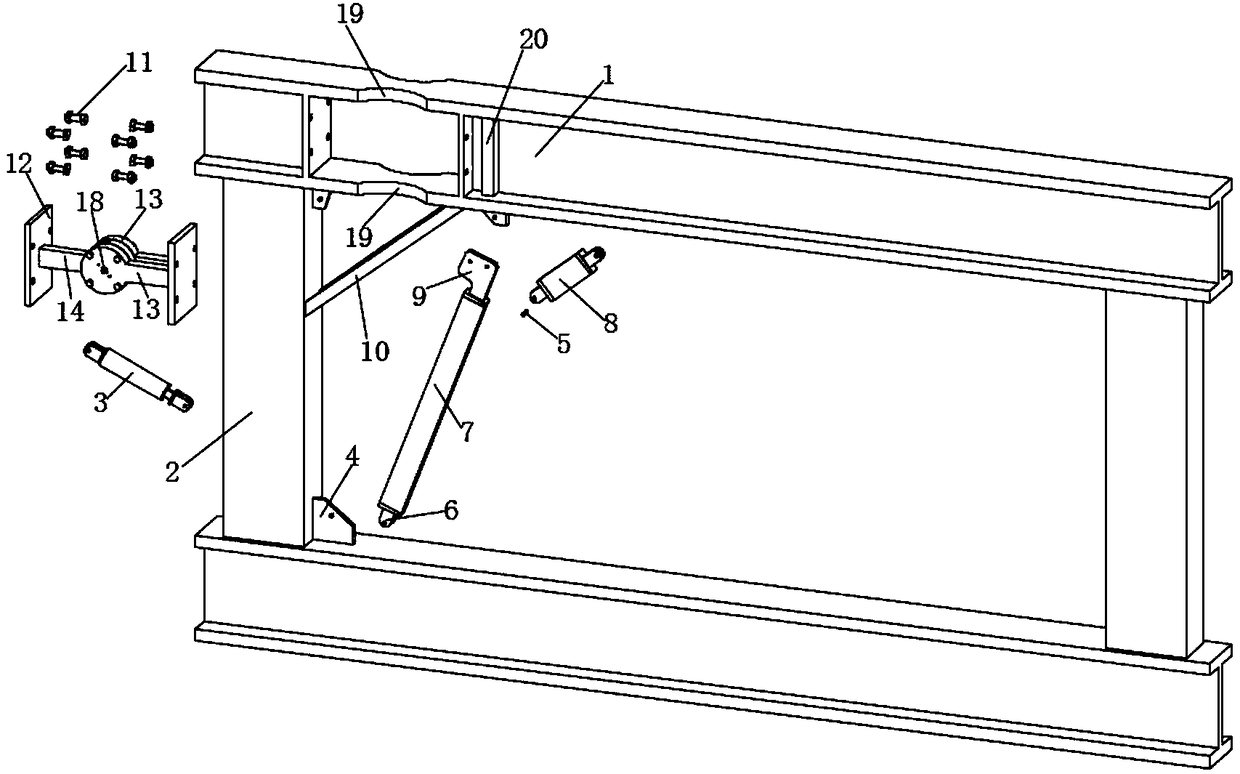

[0039] For a 30-story steel frame structure located in the fortification intensity zone of 7 degrees, according to its seismic requirements, an assembled steel structure with a replaceable beam end rotating energy-dissipating hinge and a small diagonal span lasso is used to achieve shock absorption. Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] as attached figure 1 As shown, it is a design example of an assembled steel structure containing a replaceable beam end rotating energy-dissipating hinge and a small inclined span noose in the present invention, including: assembled steel beams, assembled steel columns, dampers, gusset plates, Pins, lugs, lower links, upper links, connecting plates, trapezoidal haunches, bolts, end plates, front and rear cover plates, rotating plates, annular grooves, shear metal blocks, shear keys, shafts, wings Edge notches, web ribs. The above components are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com