Hole bottom fixing device and method utilizing hole bottom fixing device to put sleeve in coal seam for extraction

A fixing device and hole bottom technology, which is applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of tediousness, many accidents in the hole, time-consuming and laborious, etc., and achieve simple and reasonable structure design. Guaranteed grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

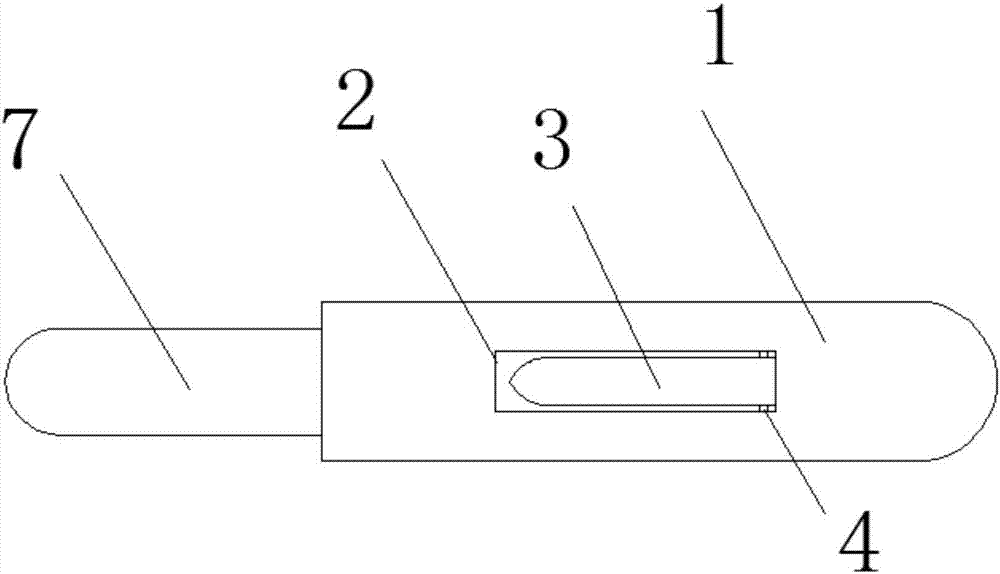

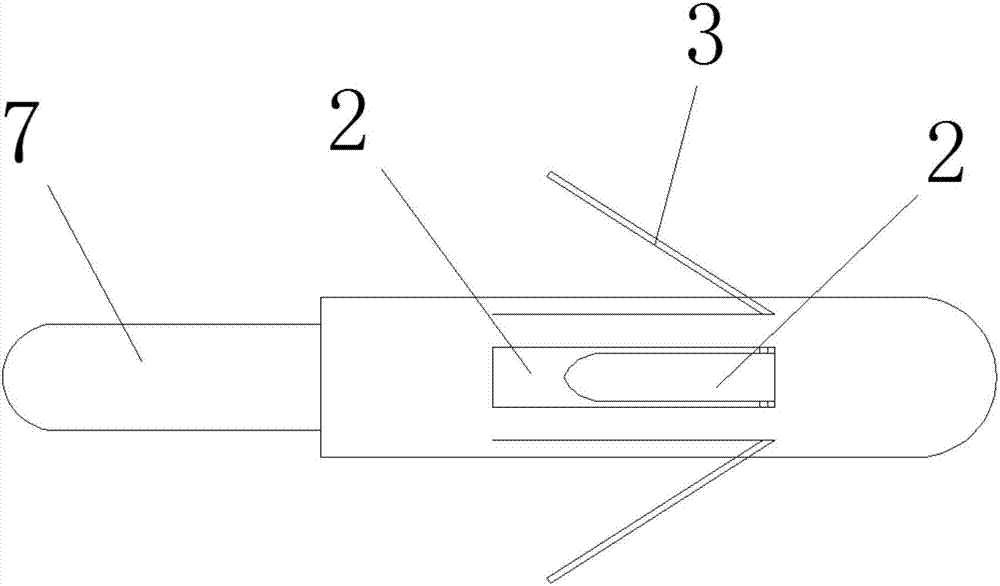

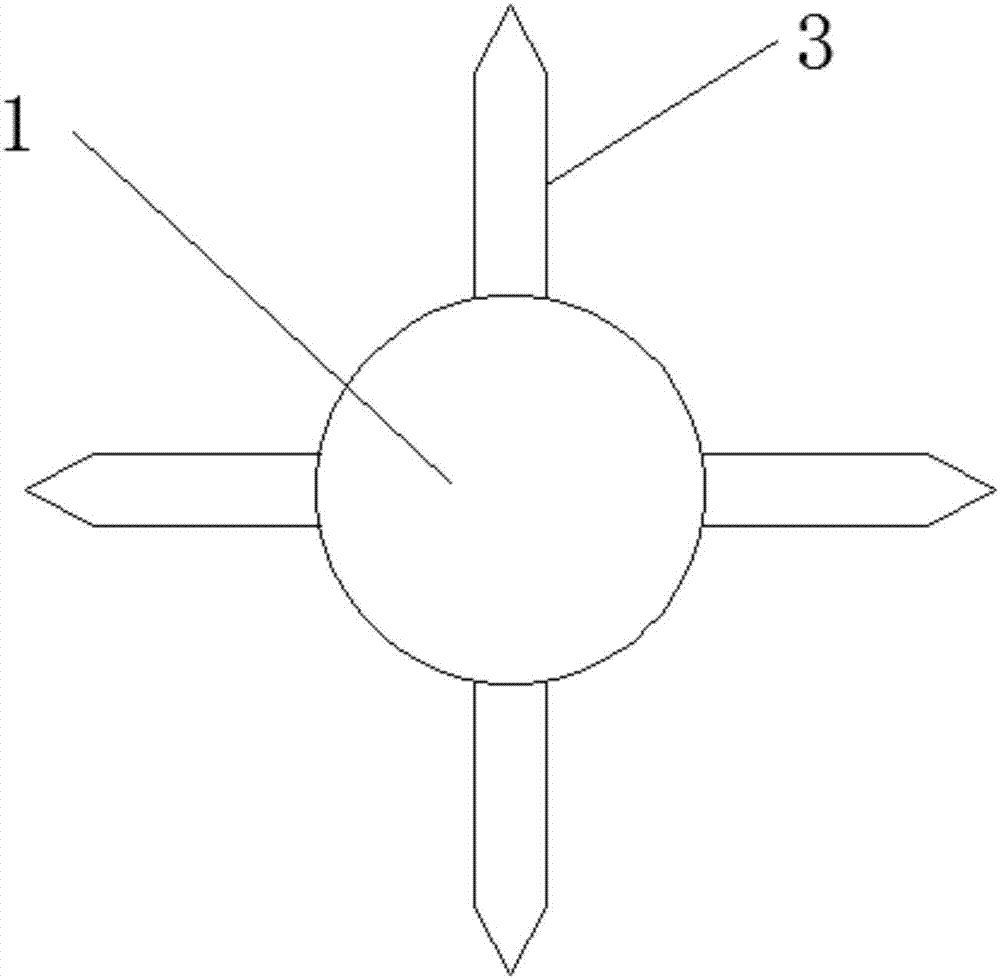

[0029] combined with Figure 1-Figure 3 , a hole bottom fixing device of the present invention, comprising a cylinder 1, a plurality of bar-shaped grooves 2 are evenly opened on the circumferential surface of the cylinder 1, and several fixed wings 3 equal in number to the bar-shaped grooves 2 are also included. The fixed wing 3 is installed in the strip groove 2, one end is rotatably connected to the bottom of the strip groove 2, and the length of the other end can be received in the strip groove 2.

[0030] Further, one end of the strip groove 2 is provided with a rotating shaft 4, and one end of the fixed wing 3 has a shaft hole, and the shaft hole is connected with the rotating shaft, and one end of the fixed wing 3 rotates inside the strip groove 2 Connect, realize the opening of fixed wing 3 by the gravity of fixed wing 3 self here;

[0031] Further, there are four strip grooves 2 and four fixed wings 3 .

[0032] Further, one end of the cylinder 1 is also fixedly conn...

Embodiment 2

[0044] combined with Figure 1-Figure 4 , a hole bottom fixing device of the present invention, comprising a cylinder 1, a plurality of bar-shaped grooves 2 are evenly opened on the circumferential surface of the cylinder 1, and several fixed wings 3 equal in number to the bar-shaped grooves 2 are also included. The fixed wing 3 is installed in the strip groove 2, one end is rotatably connected to the bottom of the strip groove 2, and the length of the other end can be received in the strip groove 2.

[0045] Further, one end of the fixed wing 3 is connected to the torsion spring 5, and the torsion spring 5 is connected to one end of the strip groove 2 through the pin shaft 6, and the fixed wing 3 is normally opened by the action of the torsion spring 5;

[0046] Further, there are four strip grooves 2 and four fixed wings 3 .

[0047] Further, one end of the cylinder 1 is also fixedly connected with a second cylinder 7 with a diameter smaller than that of the cylinder 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com