A stepless and repeatedly switchable fracturing sliding sleeve for horizontal wells

A fracturing sliding sleeve and stepless technology, applied in the direction of production fluid, wellbore/well components, wellbore/well valve devices, etc., can solve problems such as pipe string fracture, complex structure, and inability to realize infinite pole fracturing , to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with accompanying drawing:

[0052] This kind of horizontal well has stepless and repeatedly switchable fracturing sleeves, such as Figure 1 to Figure 34 As shown, it includes a first unit 1 , a second unit 2 and a third unit 3 .

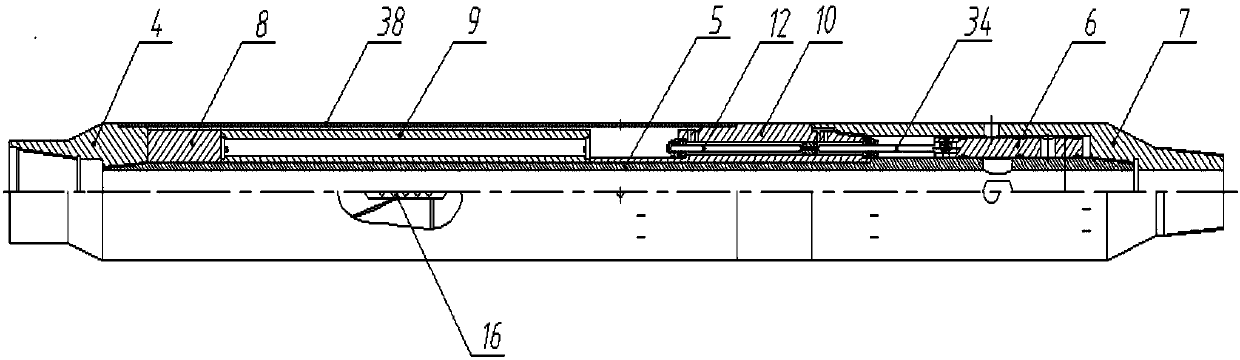

[0053] The first unit 1 is the frame support mechanism of the whole sliding sleeve system, such as Figure 4 As shown, it consists of an upper joint 4, a central pipe 5, a lower joint 7 and a sheath 38. There are four centrally symmetrical sandblasting holes 1 on the center pipe 5 . There are 4 center-symmetric sandblasting holes 2 on the inner sliding sleeve 6 . There are four sandblasting holes 3 on the lower joint 7. Since the diameter of the above sandblasting holes gradually decreases from the inside to the outside, that is, the size of the sandblasting hole 1 is larger than the size of the sandblasting hole 2 and the sandblasting hole 3, so that the overall sandbla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com