Thick-layer spreading cold mixing large gap emulsified asphalt mixture and design method thereof

A technology of emulsified asphalt and design method, applied in computing, chemical informatics, computational theoretical chemistry, etc., can solve the problems of easy aging of asphalt, affecting road performance of large void pavement, and rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

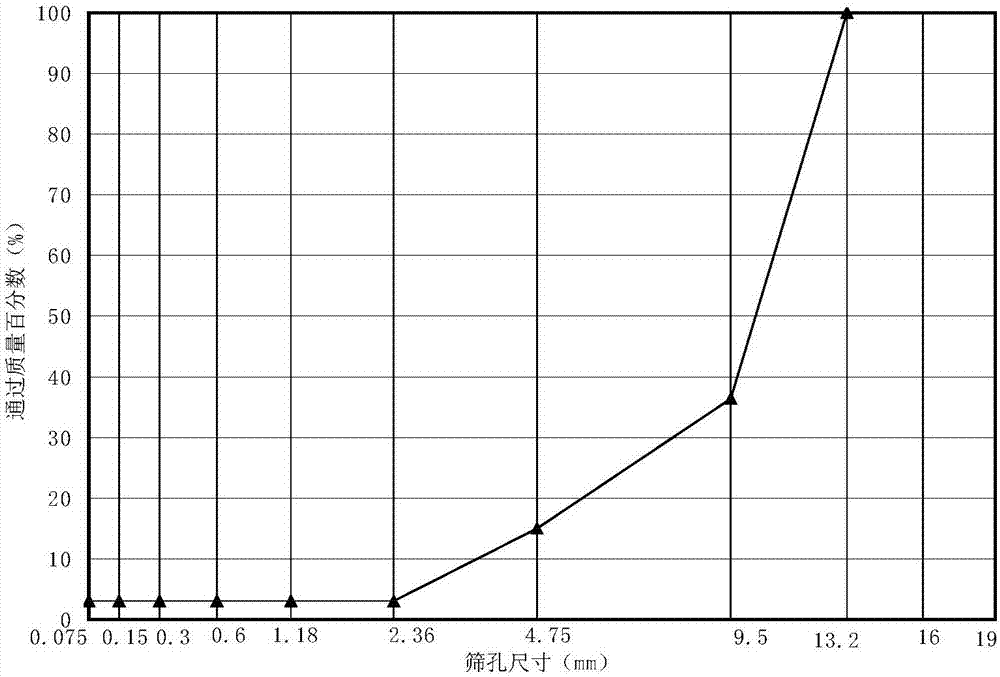

[0062] In this embodiment, the gradation design with target porosity of 22%, 25%, and 28% is taken as an example to introduce the gradation design of the present invention based on the CAVF method. According to the gradation characteristics of the matrix emulsified asphalt mixture, the present invention adopts the broken gradation. The coarse aggregate selects two aggregates with a particle size of 13.2~9.5mm and 9.5~4.75mm, and the fine aggregate selects a particle size of 2.36~ 1.18mm aggregate.

[0063] The void ratio of the main aggregate is an important parameter designed in the CAVF method. According to the relevant method of the "Highway Engineering Aggregate Test Regulations" (JTGE42-2005), the relevant physical indicators of the coarse and fine aggregates and mineral powder are measured, and the relevant physical indicators of the coarse and fine aggregates and mineral powder are measured according to the formula (1 -2) Calculate the void ratio of the main aggregate. Th...

Embodiment 2

[0085] This example provides a formula when the target porosity of the matrix emulsified asphalt mixture is 7%-30%, as shown in Table 9.

[0086] Table 9: Formula of base emulsified asphalt mixture with target air void ratio of 7% to 30%

[0087]

[0088] The emulsified asphalt used in this embodiment is a high solid content emulsified asphalt with a solid content of 70%. The standard viscosity of the high consistency emulsified asphalt is 22.6 Pa·s. The preparation method of the emulsified asphalt is as follows:

[0089] (1) Prepare raw materials in proportion to the formula:

[0090] The emulsifier is selected from France CECA-PC-30; the base bitumen is selected from TOPCO 70# heavy traffic asphalt; the water selection standard is colorless, odorless, clean and free of impurities, pH value: 6~8.5, hardness ≯ 8 degrees; auxiliary material selection PVA (polyvinyl alcohol), CaCl 2 , Hydrochloric acid; the formula is shown in Table 10 below.

[0091] Table 10 Formula of high consistency...

Embodiment 3

[0098] This example provides a preparation method of the matrix emulsified asphalt mixture of Example 2:

[0099] (1) Prepare aggregate, mineral powder, emulsified asphalt and water according to the above formula of matrix emulsified asphalt mixture;

[0100] (2) Mix the coarse and fine materials well and then add water to moisten them, then add emulsified asphalt and mix for 60 seconds, and finally add mineral powder and mix quickly until the mixture becomes brown;

[0101] (3) Put the mixture into the test mold, compact 25 times on the upper and lower sides, cure for 24 hours at a certain temperature (25°C and 110°C), and then compact 25 times on the upper and lower sides, and finally cool and demold.

[0102] This example provides the effect test of the matrix emulsified asphalt mixture of Example 2

[0103] (1) Early and late strength

[0104] The test refers to the North American standards and takes the specimens cured under certain conditions, and the strength at a certain temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com