Protective film covering method

A technology of protective film and wafer, applied in the direction of electrical components, lasers, electric solid-state devices, etc., can solve the problems of detachment, inability to perform smooth laser processing, etc., and achieve the effect of effective removal and improved cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

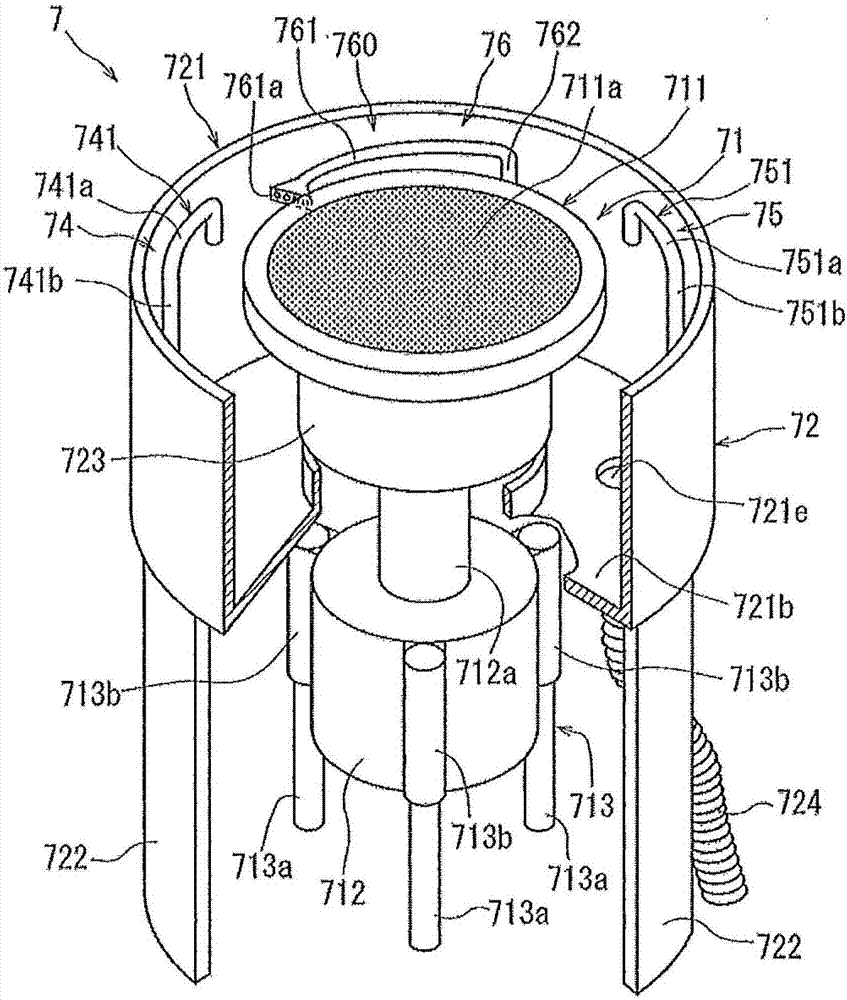

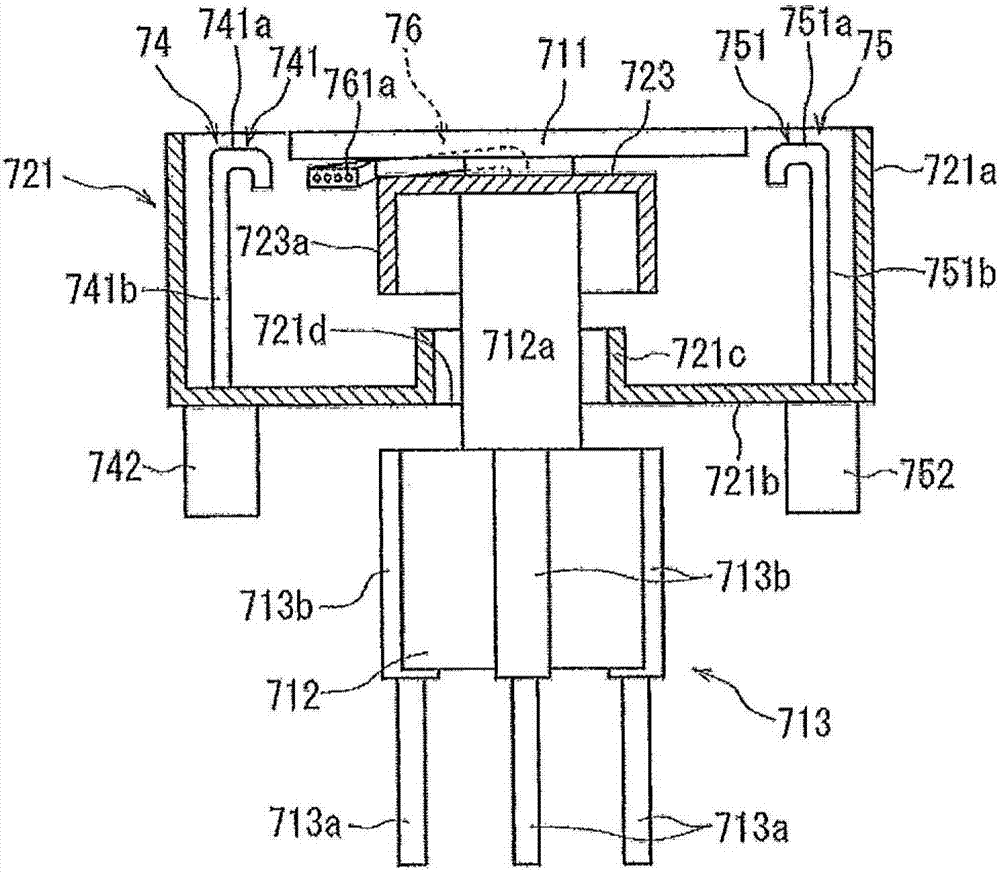

[0030] Hereinafter, preferred embodiments of the protective film coating method of the present invention will be described in detail with reference to the drawings.

[0031] exist figure 1 A perspective view of a laser processing machine equipped with a protective film covering device for carrying out the protective film covering method of the present invention is shown in .

[0032] figure 1 The laser processing machine 1 shown has an approximately cuboid device housing 2 . A chuck table 3 as a workpiece holding unit for holding a workpiece is disposed in the device housing 2, and the chuck table 3 can move in the direction indicated by the arrow X as the cutting feed direction. move. The chuck table 3 has a suction chuck support table 31 and a suction chuck 32 mounted on the suction chuck support table 31, and holds, for example, a disk-shaped semiconductor wafer as a workpiece by a suction unit not shown in the figure. It is held on the mounting surface which is the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com