Silica gel diaphragm assembly structure for loudspeaker, and preparation method

A silicone diaphragm and assembly structure technology, applied in the speaker field, can solve the problems of substandard adhesive force of the silicone diaphragm and poor waterproof performance, improve waterproof performance and product stability, facilitate access and positioning, and improve waterproof performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

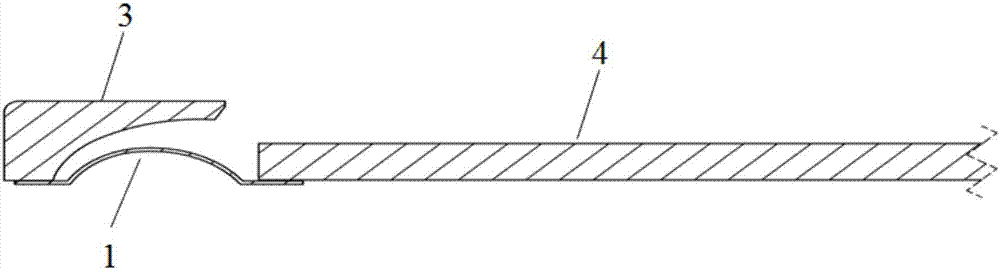

[0046] figure 2It is a cross-sectional view of a silicone diaphragm assembly structure provided in the embodiment of the present application. Wherein, the support ring 2 is a frame, which supports and positions the silicone diaphragm 1 . The silicone diaphragm 1 includes an edge portion 11, a surrounding ring 12 and a central portion 13, which are integrally structured without gaps between each other, and can completely avoid gaps between the edge portion 11 and the surrounding ring 12, and between the central portion 13 and the surrounding ring 12. Waterproof problem.

[0047] The edge portion 11 wraps the outer surface of the support ring 2, and is integrally attached to the outer surface of the support ring 2, so that there is no gap between the edge portion 11 and the support ring 2, and the waterproof performance between the edge portion 11 and the support ring 2 is enhanced. And it can save accessories such as sealing foam and rubber pads pasted on the front cover of ...

Embodiment 2

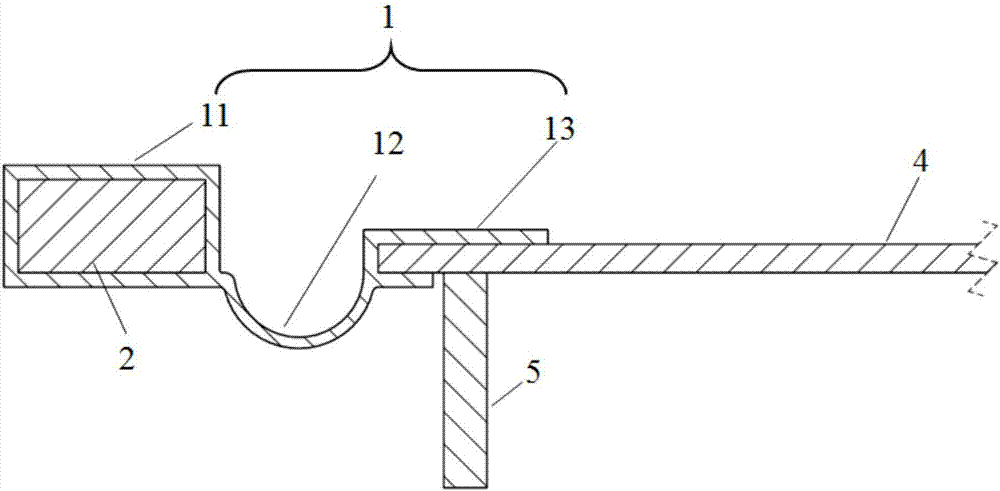

[0051] image 3 It is a cross-sectional view of a silicone diaphragm assembly structure provided in the embodiment of the present application. The support ring 2 is a frame, which supports and positions the silicone diaphragm 1 . At the same time, the support ring 2 replaces the front cover, which simplifies the product structure. The inner side of the support ring 2 is formed with a plurality of slopes, and the edge portion 11 is closely bonded to the multiple slopes with angles inside the support ring 2 , which is stronger than a single plane bonding, and the waterproof performance can also be improved.

[0052] The edge part of the middle sticker 4 is formed as a folded edge 41, and the folded edge 41 is bonded to the central part 13, thereby increasing the bonding area between the central part 13 and the middle sticker 4, and also increasing different bonding surfaces. Compared with the traditional process, only one plane of the middle sticker 4 is bonded, and the waterp...

Embodiment 3

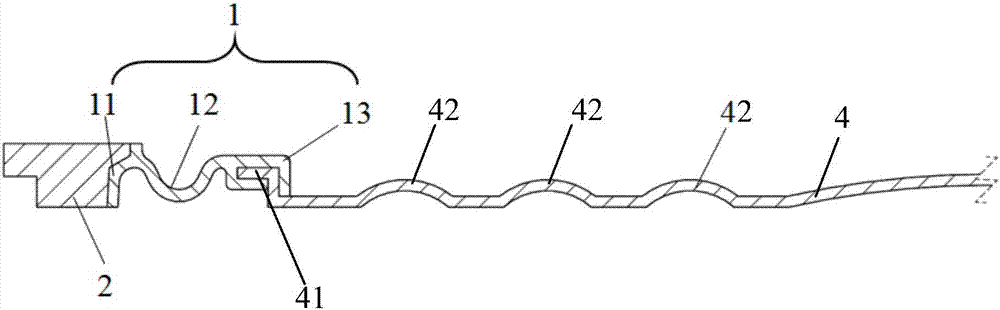

[0055] Figure 4 A cross-sectional view of a silicone diaphragm assembly structure provided in an embodiment of the present application, Figure 5 is an exploded view of the silicone diaphragm assembly structure. The supporting ring 2 is a frame, and plays a role of positioning and supporting the silicone diaphragm 1 during assembly. The edge portion 11 is attached to the upper surface and the inner surface of the support ring 2, and the central portion 13 is bonded to the upper surface and part of the side edges of the middle sticker 4. On the surface, the waterproof performance and adhesion can be improved by increasing the vertical bonding surface or bonding surface.

[0056] The size of the support ring 2 can match the design size of the loudspeaker, or can be larger than the design size of the loudspeaker. When it is larger than the design size of the speaker, after the speaker assembly is completed, it can be cut along the Figure 4 Cut at the position indicated by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com