Viscus removing structure used for fish deep-processing and viscus removing method

A technology of deep processing and viscera, applied in the field of visceral removal structure, can solve the problems of low efficiency, low sanitation and high labor intensity of artificial methods, and achieve the effect of improving sanitation, reducing labor intensity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

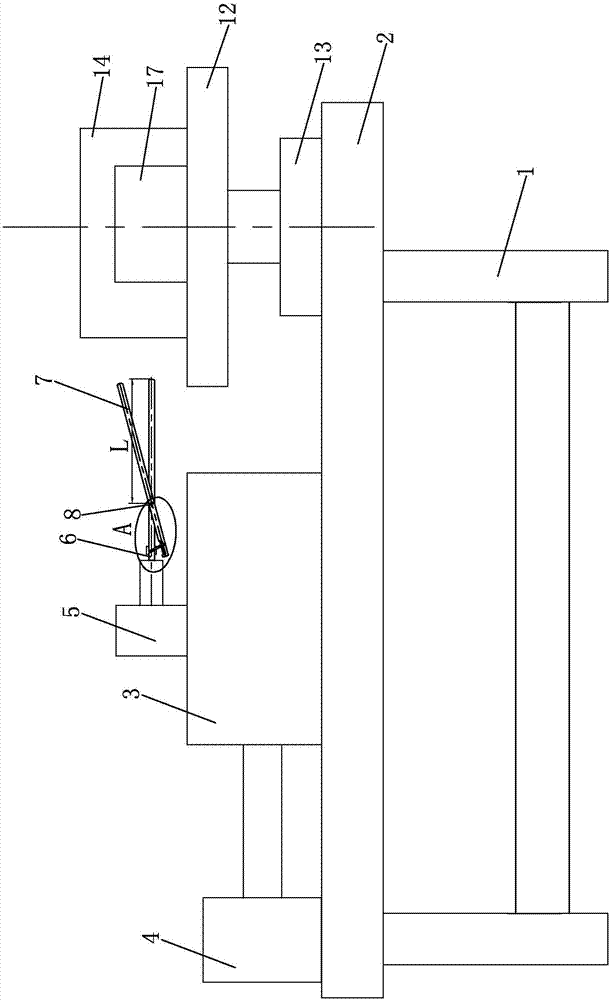

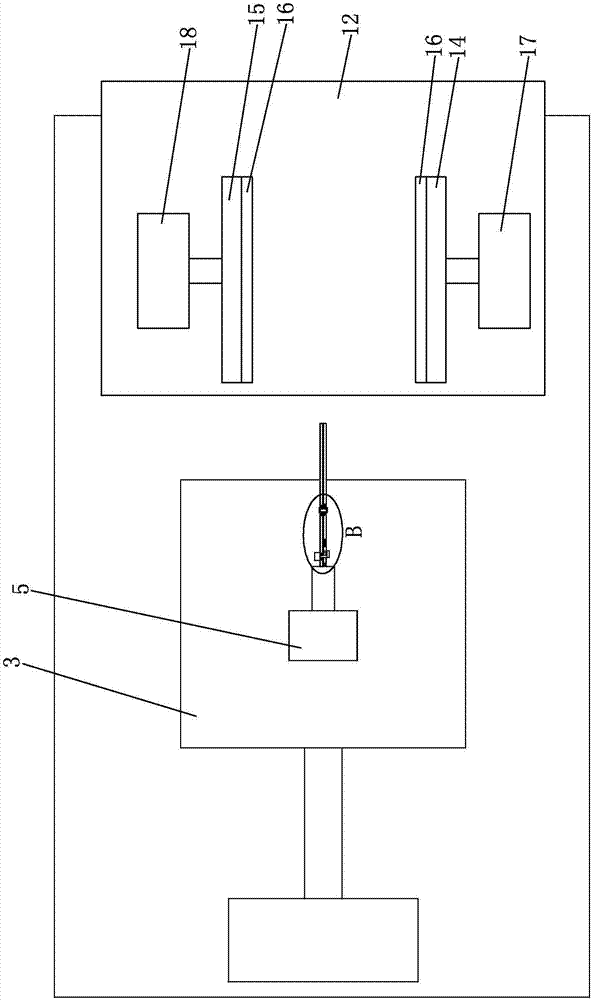

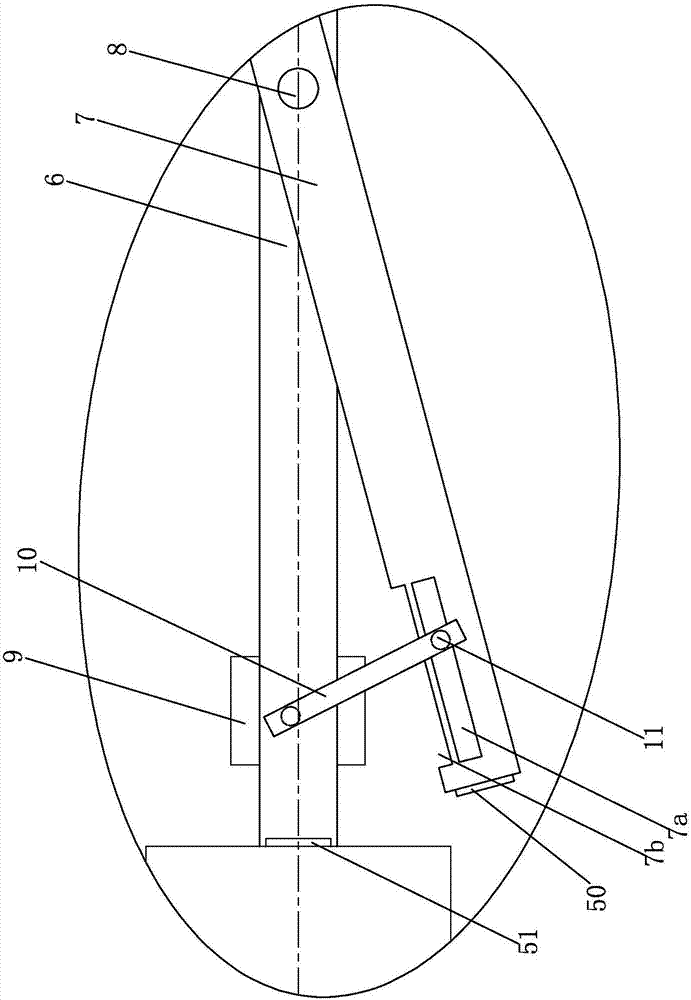

[0033] like figure 1 , 2 , 3 and 4, a fish deep-processing visceral removal structure mainly consists of a support frame 1, a horizontal plate 2, a slide plate 3, a push cylinder 4, a rotating motor 5, the first removal bar 6, the second removal bar 7, the first Parts such as pin shaft 8, small motor 9, connecting bar 10 and the second pin shaft 11 are formed. Wherein, the support frame 1 is a welded frame structure, and a horizontal plate 2 is fixed on the top surface of the support frame 1. The height of the horizontal plate 2 from the ground is 0.9-1.1m, which is convenient for the operator to sit and operate.

[0034] On the horizontal plate 2, a slide plate 3 is slidably fitted by the guide rail slider assembly, and the left end of the slide plate 3 is connected with the push cylinder 4 piston rod on the horizontal plate 2, so that it can slide left an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Straight line length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com