A tundish with controlled deflection deformation

A tundish and arc-shaped technology, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of deflection and deformation, so as to improve the service life, increase the number of continuous pouring furnaces, and avoid excessive temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

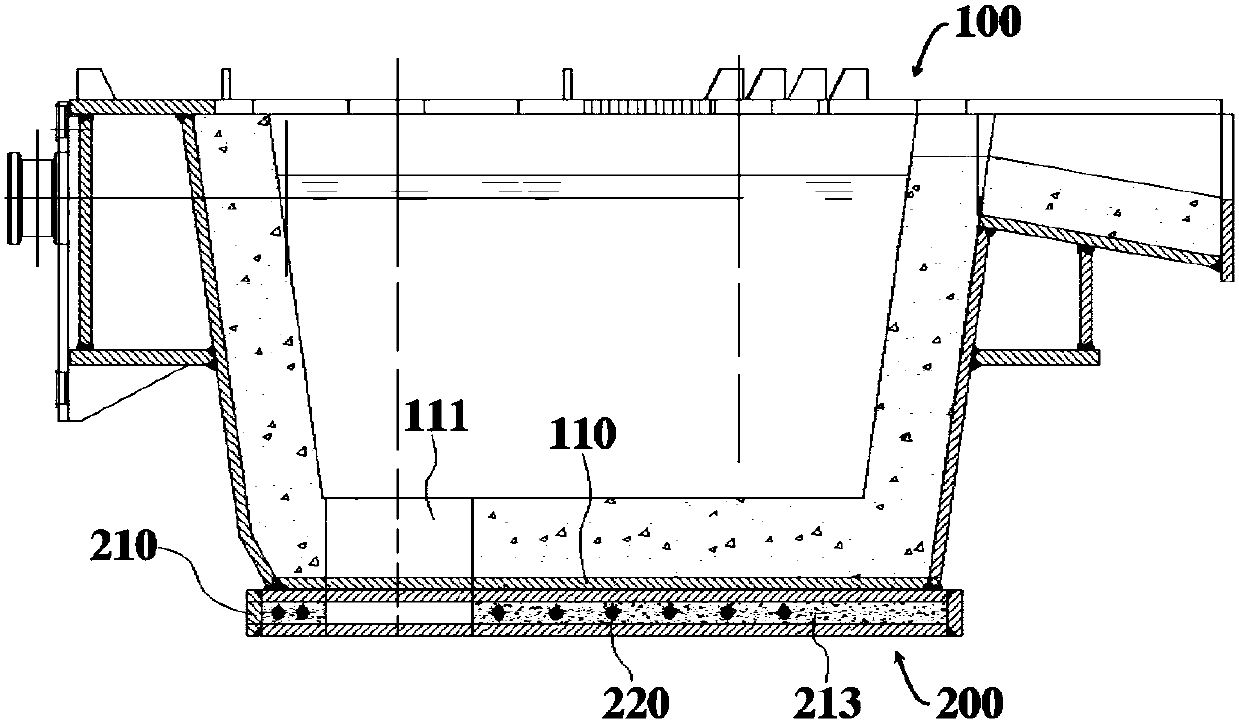

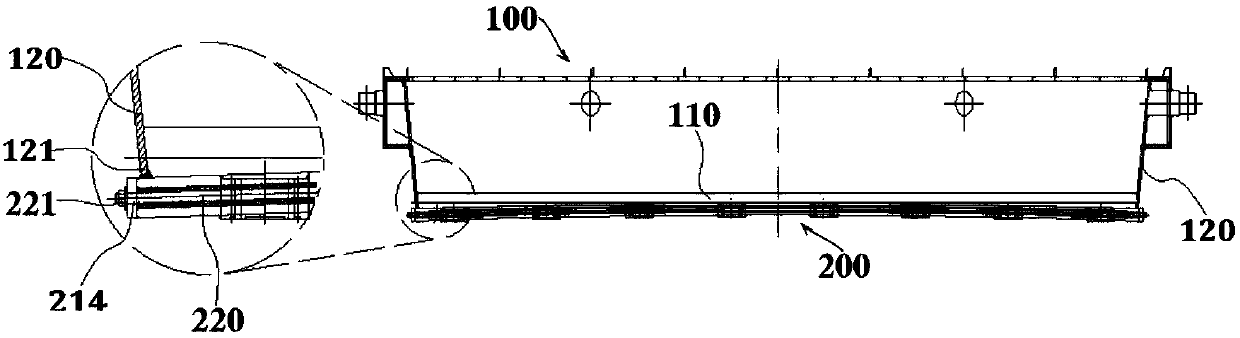

[0038] combine Figure 1-4 As shown, a tundish with controllable deflection deformation of the present invention includes a tundish main body 100 and a prestress applying mechanism 200, the tundish main body 100 includes a tundish bottom plate 110 and a tundish side plate 120, and the tundish bottom plate 110 is horizontal Set, tundish side plate 120 is installed around tundish bottom plate 110, tundish bottom plate 110 and tundish side plate 120 constitute the molten steel container of top opening (as figure 1shown). The tundish nozzle 111 is opened on the bottom plate 110 of the tundish, and the opening 211 corresponding to the nozzle is also provided on the prestressing mechanism 200 .

[0039] The middle part of the above-mentioned prestress applying mechanism 200 is curved upward in an arc shape, and the arc-shaped top 201 of the prestress applying mechanism 200 is in contact with the tundish bottom plate 110, and the arc-shaped top 201 applies prestress to the tundish b...

Embodiment 2

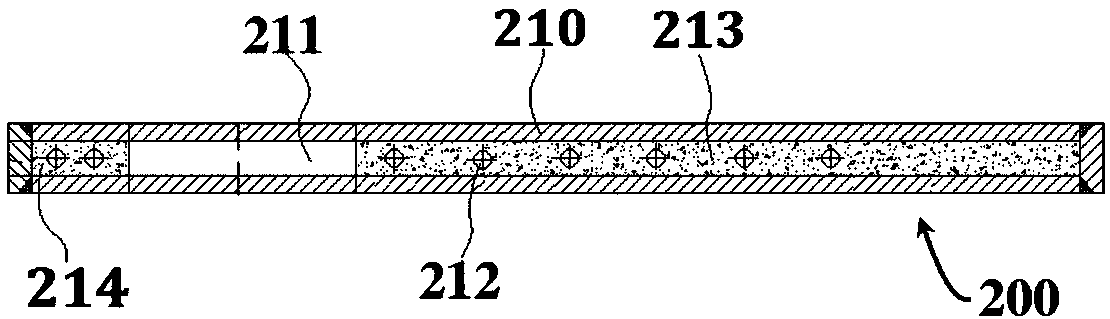

[0075] The basic content of this embodiment is the same as that of Embodiment 1, except that the 10-strand billet continuous casting machine of 3#10 machine of a certain company’s No. 1 and Table 2, it can be seen that the distance between the centers of steel bar sleeves 212 is 100 mm, and the diameter of steel bar sleeves 212 is The diameter of the prestressed steel bar 220 is The deformation of the designed prestress applying mechanism 200 is D=70mm, and the designed prestress of the prestress applying mechanism 200 is 500MPa.

[0076] A process of applying prestress to the bottom plate of the tundish in this embodiment:

[0077] The components of heat-resistant concrete are composed according to the following mass parts: 43kg of cement, 25kg of refractory aggregate, 5kg of filler, 8kg of additive, 1kg of antirust agent, 1kg of water reducing agent, and 5kg of water; the above cement is C60 Portland cement , the filler is composed of copper powder, converter wind-quench...

Embodiment 3

[0084] The basic content of this embodiment is the same as embodiment 1, the difference is:

[0085] The components of heat-resistant concrete are composed according to the following mass parts: 40kg of cement, 30kg of refractory aggregate, 8kg of filler, 15kg of additive, 1kg of antirust agent, 1kg of water reducing agent, and 5kg of water; the above cement is C60 Portland cement , the filler is composed of copper powder, blast furnace slag, and gravel in a ratio of 1:1:1, the copper powder is deoxidized copper powder, and the particle size of the filler is continuously graded granular material of 3 to 10 mm. Described additive is made up of water glass and sodium fluorosilicate, and quality is water glass 9kg, sodium fluorosilicate 6kg respectively.

[0086] When the tundish of this embodiment is used for continuous casting, the number of continuous casting furnaces reaches 58 furnaces. The tundish of this embodiment does not have bad plastic deformation, and the overall st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com