Special additive for rubber vulcanization accelerator cbs granulation, preparation method and granulation method of the additive

A technology of rubber vulcanization and additives, which is applied in the field of rubber vulcanization accelerator granulation additives and rubber vulcanization accelerator granulation. It can solve the problems of not advocating the use, easy breakage, and affecting rubber products, so as to reduce particles. Broken, the strength is uniform and close, and the effect of reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

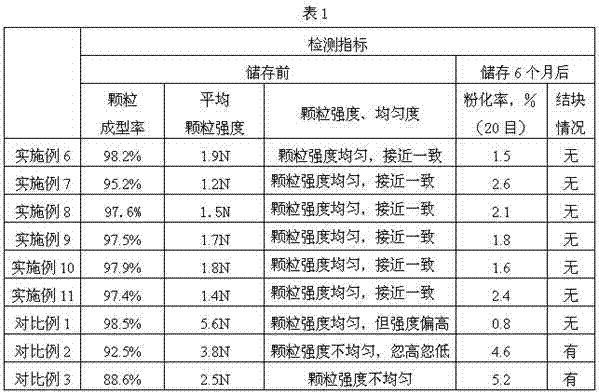

Examples

Embodiment 1

[0028] The additive formula is: alkylphenol polyoxyethylene ether (molecular formula is C 34 h 62 o 11 , average molecular weight 646.85) 600 kg, 15# industrial white oil 200 kg, ethylene-vinyl acetate copolymer emulsion (molecular formula (C2H4)x.(C4H6O2)y, vinyl acetate content: 70% to 95%, average molecular weight 2000) 80 kg, 1120 liters of water.

[0029] The preparation method is as follows: put water, alkylphenol polyoxyethylene ether, 15# industrial white oil and ethylene-vinyl acetate copolymer into a 3000-liter reactor, stir and raise the temperature to 48°C and keep it warm for 90 minutes to obtain the additive product.

Embodiment 2

[0031] The additive formula is: 300 kg of alkylphenol polyoxyethylene ether (average molecular weight 646.85), 300 kg of 15# industrial white oil, 100 kg of ethylene-vinyl acetate copolymer (vinyl acetate content: 70%-95%, average molecular weight 2000) , 1300 liters of water.

[0032] The preparation method is the same as in Example 1.

Embodiment 3

[0034] The additive formula is: alkylphenol polyoxyethylene ether (average molecular weight 646.85) 1000 kg, 15# industrial white oil 100 kg, ethylene-vinyl acetate copolymer (vinyl acetate content: 70% ~ 95%, average molecular weight 2000) 40 kg , 860 liters of water.

[0035] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com