High-quality and low-temperature instant black tea powder and preparation technology thereof

A preparation process and high-quality technology, applied in the field of black tea powder, can solve the problems of inability to meet the requirements of low-temperature beverages, poor quality of tea soup, inability to achieve low-temperature instant dissolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

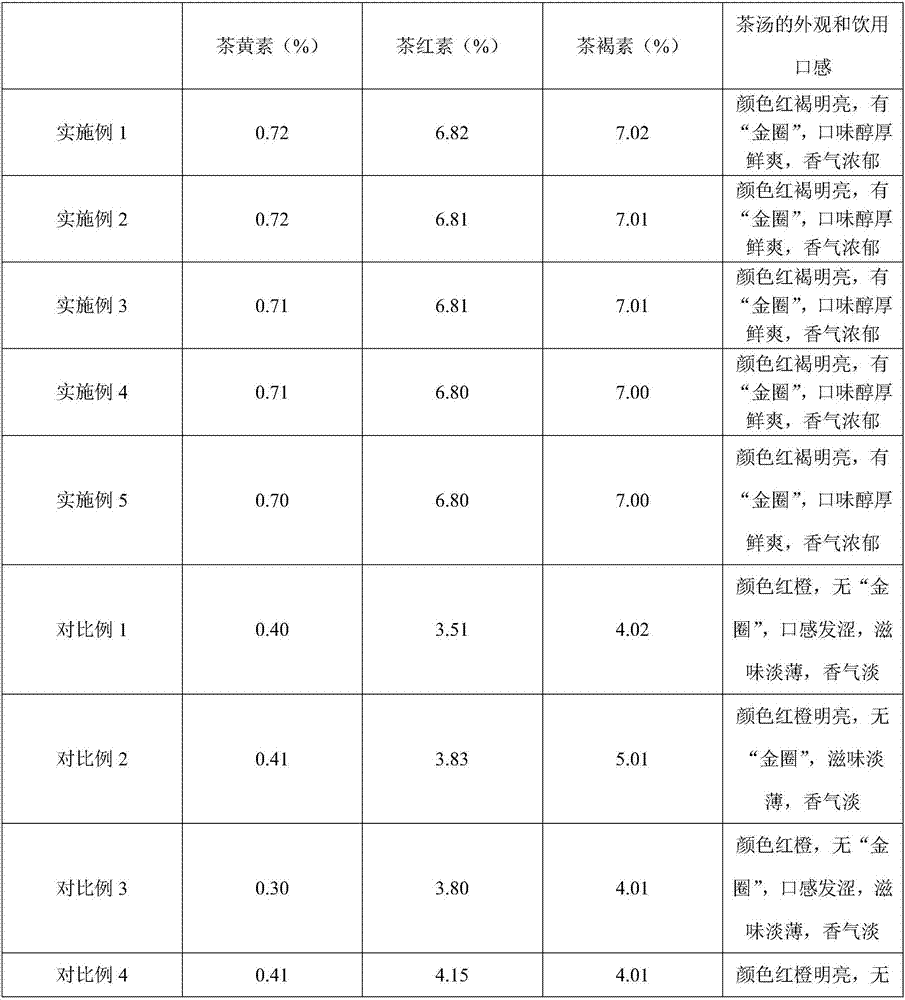

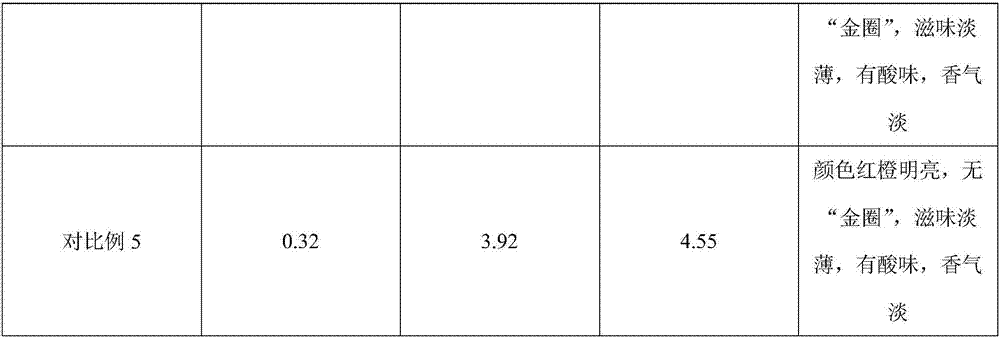

Examples

Embodiment 1

[0029] A kind of preparation technology of high-quality low-temperature instant black tea powder, concrete steps are as follows:

[0030] (1) Select the fresh leaves of tea leaves grown in the current year, and carry out withering, rolling, stacking and first fermentation treatment in sequence;

[0031] (2) Add the tea leaves after the first fermentation into water at 70°C, then add sodium alginate, and stir for 5 minutes while hot. The weight-volume ratio of the tea leaves after the first fermentation, sodium alginate and water is 1g:0.1 g: 200mL;

[0032] (3) Filter to obtain the first filtrate and the first filter residue, freeze and grind the first filter residue in a freezer grinder for 20 minutes to obtain a powder, then add the powder to 1 / 4 weight of the first filtrate while stirring, 300W microwave Treat for 3 minutes to obtain a mixed slurry;

[0033] (4) Add the remaining first filtrate to the mixed slurry, add 0.01 times the weight of lemon juice dropwise to the ...

Embodiment 2

[0039] A kind of preparation technology of high-quality low-temperature instant black tea powder, concrete steps are as follows:

[0040] (1) Select the fresh leaves of tea leaves grown in the current year, and carry out withering, rolling, stacking and first fermentation treatment in sequence;

[0041] (2) Add the tea leaves after the first fermentation to water at 80°C, then add sodium alginate, and stir for 7 minutes while hot. The weight-volume ratio of the tea leaves after the first fermentation, sodium alginate and water is 1g:0.2 g: 300mL;

[0042] (3) Filtrate to obtain the first filtrate and the first filter residue, freeze and grind the first filter residue in a freezer grinder for 30 minutes to obtain a powder, then add the powder to 1 / 4 weight of the first filtrate while stirring, 450W microwave Process for 4 minutes to obtain a mixed slurry;

[0043] (4) Add the remaining first filtrate to the mixed slurry, add 0.02 times the weight of lemon juice dropwise to the ...

Embodiment 3

[0049] A kind of preparation technology of high-quality low-temperature instant black tea powder, concrete steps are as follows:

[0050] (1) Select the fresh leaves of tea leaves grown in the current year, and carry out withering, rolling, stacking and first fermentation treatment in sequence;

[0051] (2) Add the tea leaves after the first fermentation into water at 70°C, then add sodium alginate, and stir for 7 minutes while hot. The weight-to-volume ratio of the tea leaves after the first fermentation, sodium alginate and water is 1g:0.1 g: 300mL;

[0052] (3) Filtrate to obtain the first filtrate and the first filter residue, freeze and grind the first filter residue in a freezer grinder for 20 minutes to obtain a powder, then add the powder to 1 / 4 weight of the first filtrate while stirring, 450W microwave Treat for 3 minutes to obtain a mixed slurry;

[0053] (4) Add the remaining first filtrate to the mixed slurry, add 0.02 times the weight of lemon juice dropwise to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com