Temper mill base plate adjusting method

An adjustment method and technology of a leveling machine, which are applied in the directions of cleaning methods and utensils, chemical instruments and methods, and cleaning methods using tools, etc., can solve the problems of difficult control of adjustment amount, long resource occupation time, etc., and achieve high construction efficiency, The effect of good installation quality and reasonable construction process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as Figures 1 to 8 As shown, a method for adjusting the bottom plate of a leveling machine, which includes the following steps:

[0032] 1. Thoroughly clean and treat the surface of the bottom plate: The surface of the bottom plate is thoroughly cleaned and treated by removing the butter on the surface with a spatula, and then scrubbing it with cleaning oil;

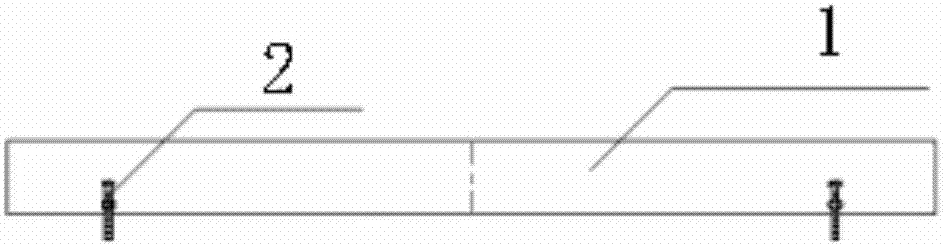

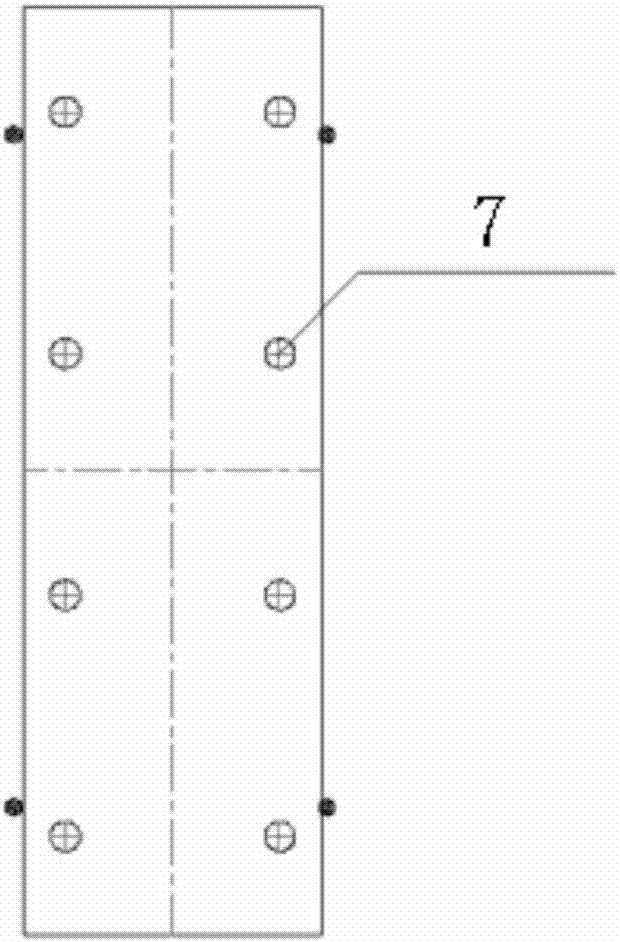

[0033] 2. Make the installation elevation adjustment auxiliary tool 2 on the base plate 1: the installation method of the elevation adjustment auxiliary tool 2 is to weld nuts on both sides of the length direction of the base plate, close to the anchor bolts 7, and the nuts are provided with rotatable screws. The nuts The specification is M48, and the quantity is 4 pieces, such as Figure 1-3 shown;

[0034] 3. Base plate elevation adjustment: use the elevation adjustment auxiliary tool 2 installed in step 2 and the level to adjust the base plate 1 elevation;

[0035] 4. Install the center line adjustment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com